Challenges / research priorities

Quality and Reproducibility:

Despite the numerous advantages of the jet dispensing process, the technology still faces challenges in the reproducibility and stability of print quality. Inaccuracies in the printing and post-processing stages lead to variations in conductivity, which can fluctuate by ±10% even in optimized systems. This negatively impacts the functionality and cost of the final products. Additionally, process-related deviations in geometry and line cross-sections further affect functionality.

Insufficient reproducibility of printed structures currently hinders industrial series production. However, precise inline quality control and dynamic process regulation can significantly enhance the reliability of the process.

Objective:

- Optimization of process stability: Development and implementation of process controls to minimize fluctuations in the printing and post-processing stages.

- Inline quality control: Introduction of contactless monitoring methods, such as high-frequency eddy current testing, for real-time verification of conductivity and geometry of printed structures.

Manufacturing and Evaluation of Functional Elements:

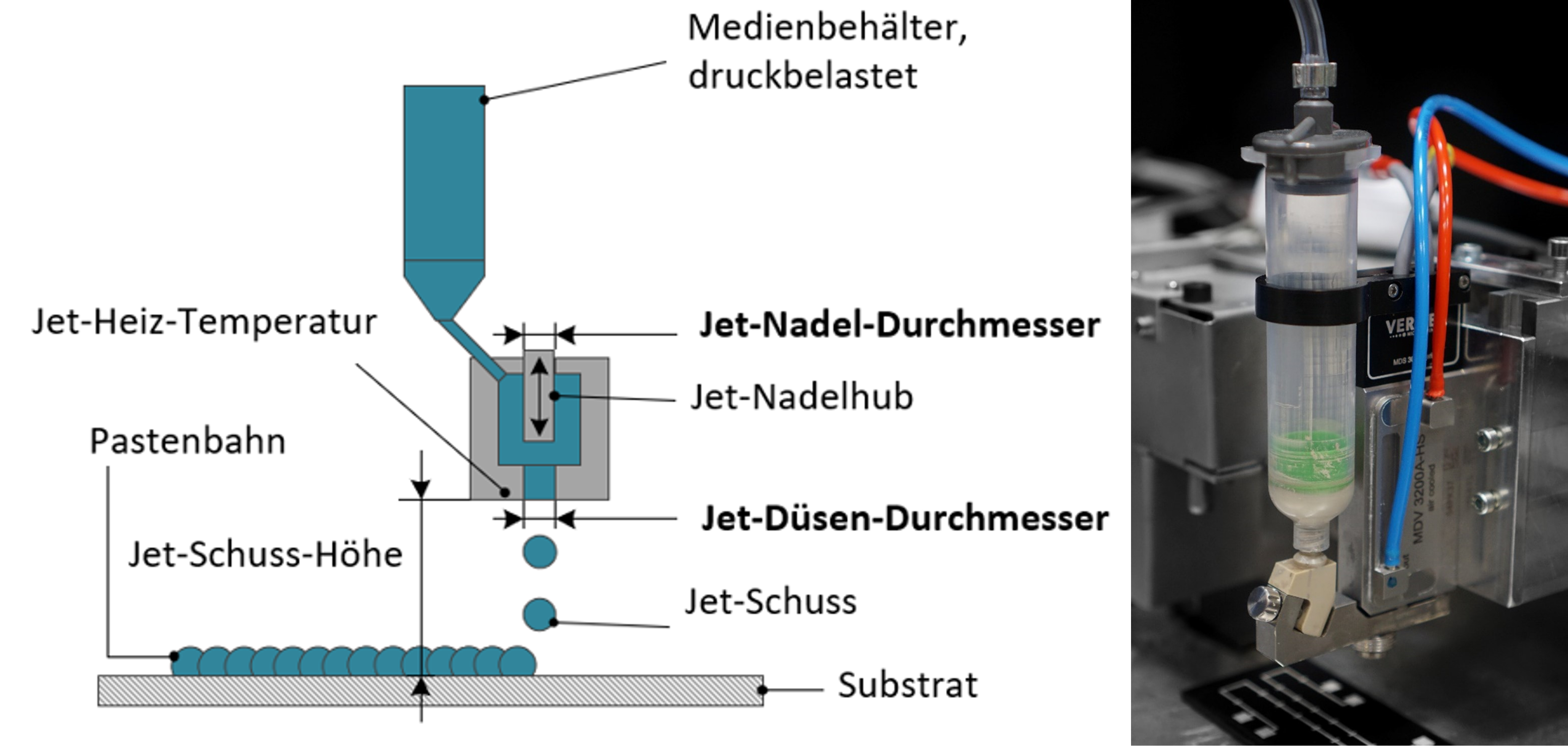

Using jet dispensing, components such as capacitive or piezoelectric sensors, heating and lighting elements, as well as signal and contact lines, can be directly printed onto various substrates—whether glass, ceramics, metals, or flexible plastics.

Special functional materials, such as conductive inks containing silver, copper, or polymers, as well as piezoelectric and resistive materials, are used in the process. The precise handling of these materials imposes high demands on print quality, which is currently one of the biggest challenges. Variations in the production process affect the printing accuracy and conductivity of the printed elements, potentially leading to functional limitations. This variability also increases production costs due to rework or scrap caused by inconsistent results.

To further advance jet dispensing technology for the production of functional electronic components such as sensors and other elements, our objectives focus on the following technological development aspects:

- Printing of commercially available materials: Optimization of the printing process for market-available functional pastes to ensure high compatibility and efficiency in the production of various components.

- Quality and reproducibility testing: Examination of printed elements for precision and repeatability to ensure consistent and reliable product quality.

- Process influence on structural quality: Analysis of the effects of various process parameters (printing speed, drying, etc.) on the structure and functionality of printed components to achieve process optimization.

- Proof of function and endurance tests: Conducting functional tests and long-term tests of printed elements to validate their reliability, lifespan, and stability under real conditions.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology