Fraunhofer IWU at Formnext, November 19–22, 2024, Hall 11.0/Booth E38

Custom Print Heads for 3D Printing: Achieving Individual and Highly Efficient Functional Integration

Wire or Fiber Encapsulating Additive Manufacturing (WEAM/FEAM) could significantly simplify the industrial production of components that require the integration of complex yet compact wiring, sensors, actuators, or lighting systems – by directly printing these components into the parts. The FEAM process uses glass fibers instead of wires, which are coated with a polymer and applied to any substrate without affecting its optical properties. This technology enables the creation of customizable lighting elements, sensors, or data conductors on 2D or 3D surfaces. A new development at Fraunhofer IWU: the Automated Cable Assembly (AuCA). Conventional robotics fails to produce and automatically lay flexible cable bundles in vehicles; AuCA, however, manufactures the wiring using a robot-guided way on a component and fixes it with a polymer.

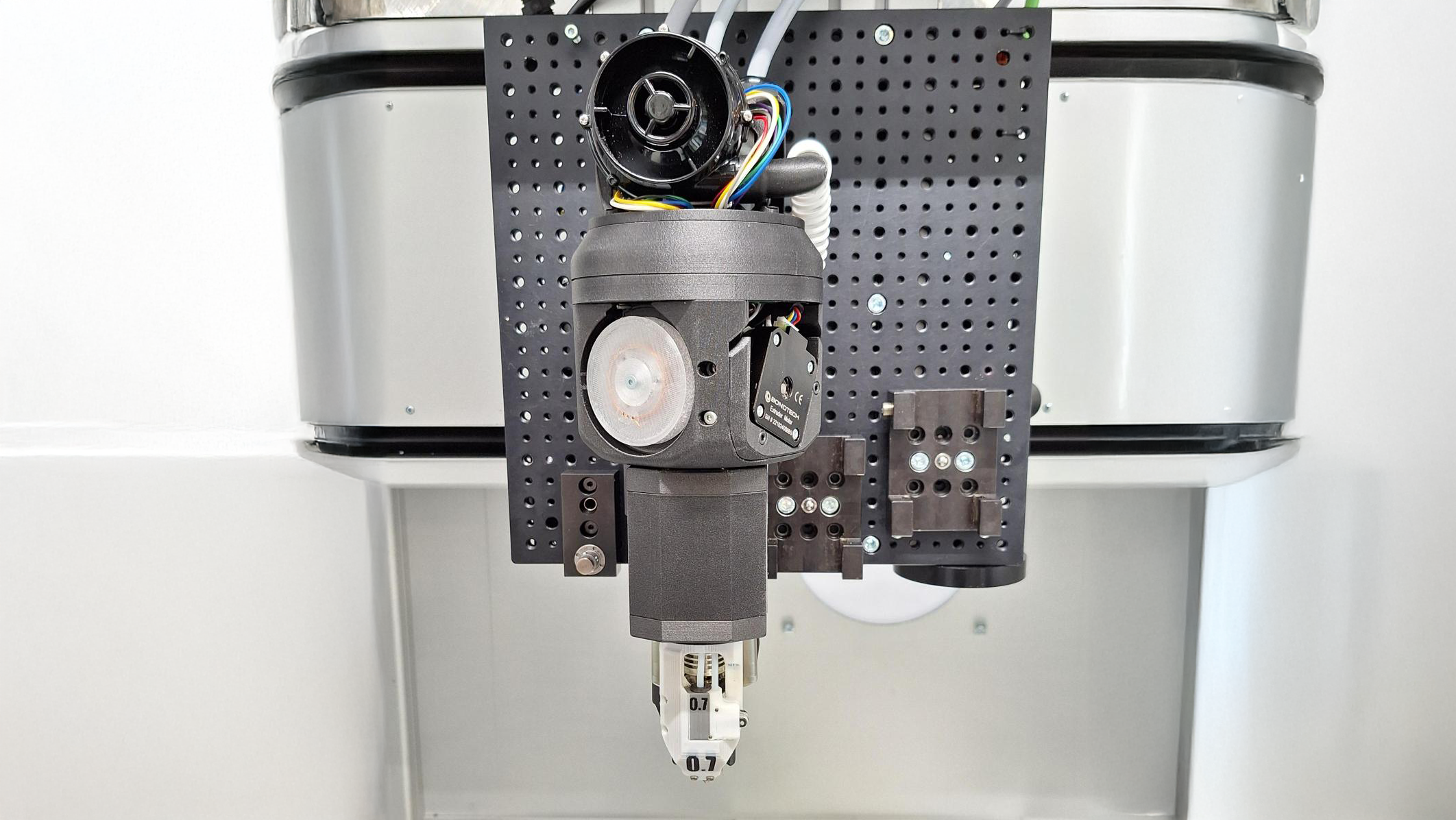

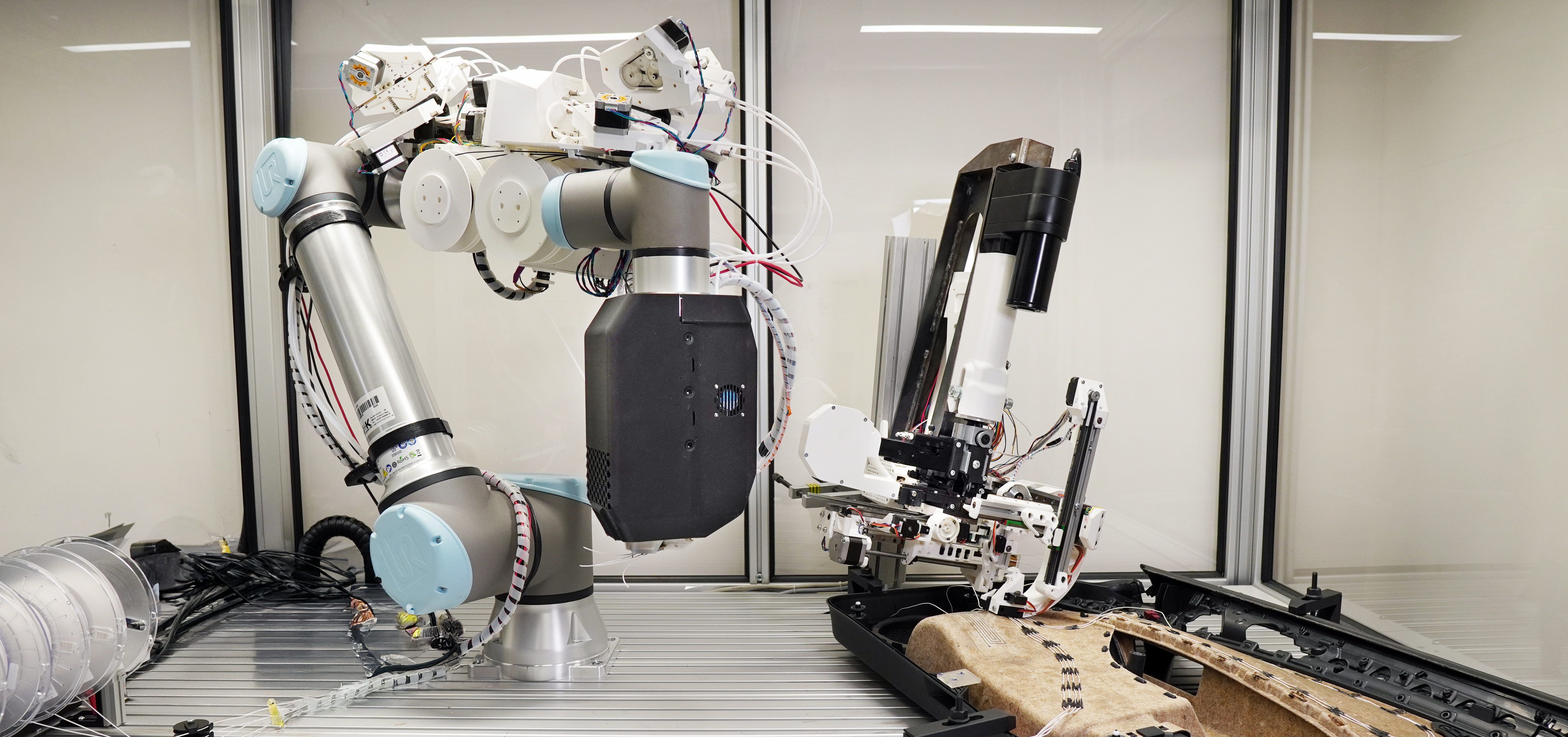

The team led by Lukas Boxberger at Fraunhofer IWU offers a variety of print heads for a wide range of manufacturing tasks, which the IWU team can further customize to specific product requirements.

Printing custom wiring harnesses in a car plant

A wiring harness for an automobile consists of several cables with different lengths, cross-sections, and terminal connectors. For a robotic system, both the assembly and installation of a cable system several kilometers long would be extremely difficult to manage. Such processes would require numerous cameras, sensors, and intricate processing steps. For this reason, even today, the entire process chain from assembling the cables to installing them in the vehicle is still characterized by a lot of painstaking manual labor.

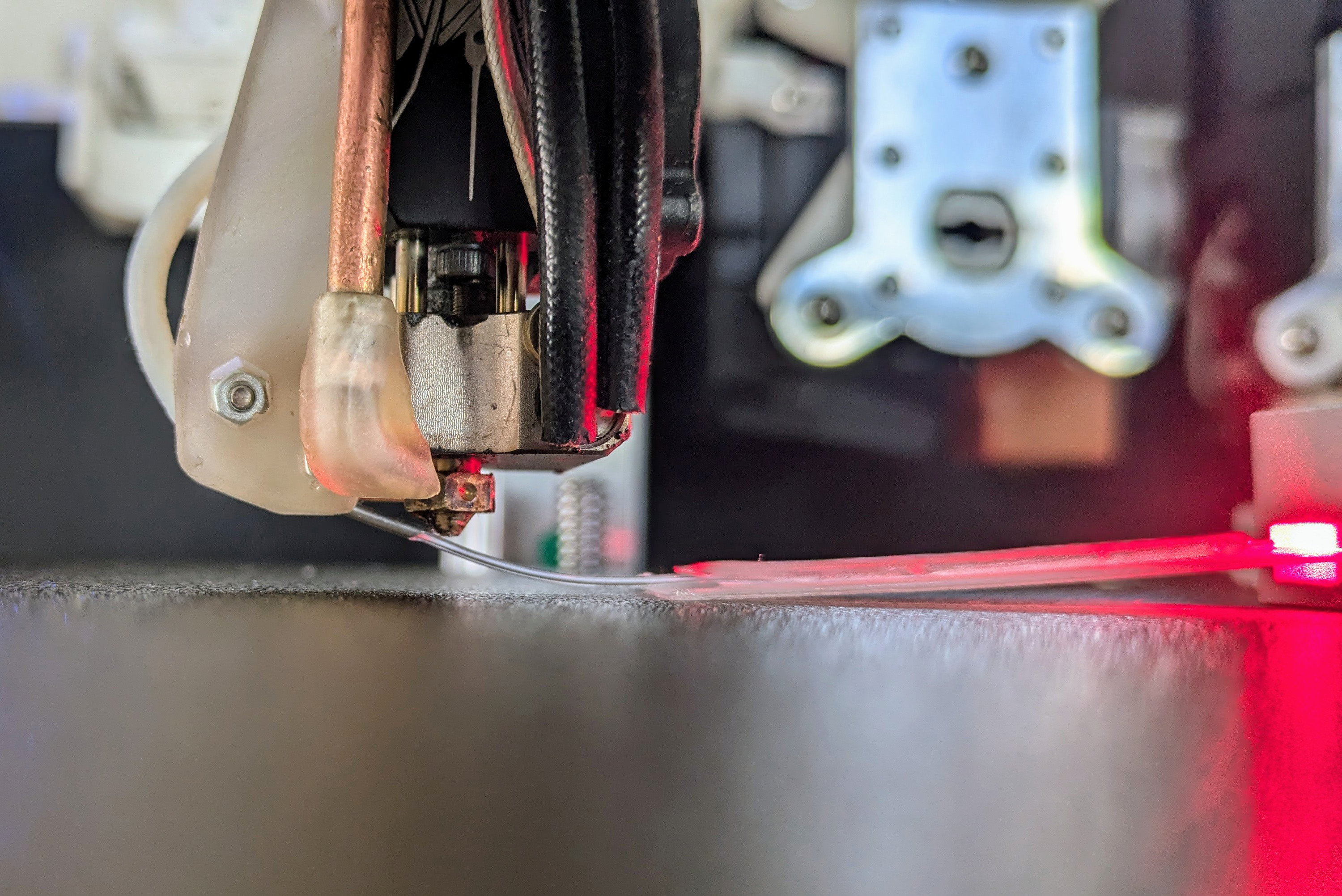

With the Automated Cable Assembly (AuCA), Fraunhofer IWU has completely rethought cable laying and combined it with 3D printing technology, allowing flexible cables to be deposited directly from an endless reservoir without the need to handle them manually. In addition, the researchers have developed a tool head that equips the laid cables with. The cable-laying concept is automated, does not require image processing, and uses an efficient laying system directly on the final component. This technology eliminates the need for cable pre-assembly, harness configuration, transport, and installation. Such a system can thus replace several manual labor stations and apply wiring harnesses on the component next to the production line of a car, for example. AuCA reduces the wiring harness to its core components: individual cables, necessary contacts, and application-specific adhesives. This approach saves weight and eliminates the need for additional materials for transport protection.

Applications similar to automotive wiring harnesses exist in all areas of cable integration, from control cabinets to consumer electronics.

Using FEAM to leverage the benefits of fiber optics for faster data transfer or create flat, flexible, and lightweight lighting ystems

Instead of (coated) cables, fiber optic strands can also be applied to various substrates using printing technology. In Fiber Encapsulating Additive Manufacturing, a single fiber or fiber bundle is printed onto the component by a print head and encapsulated with a polymer coating. This approach allows for depositing fiberglass tracks directly onto the final component in any desired shape. With the FEAM technology, the researchers aim to push the boundaries of fiber optic integration to develop cost-effective and design-flexible solutions for industrial applications. Fraunhofer IWU is working on methods that enable fully automated integration of fiber optic elements and is developing print head systems that are faster, more precise, and more efficient in manufacturing. Products with optical fibers that can be directly applied to (injection-molded) parts require shorter processing times and fewer components.

Comparable cost benefits can be achieved when this technology is used to directly apply optical fibers onto components. At Formnext, Fraunhofer IWU will showcase a print head that can achieve deposition speeds of up to 50 millimeters per second for fiber diameters ranging from 0.2 to 1 millimeter, without the need for special requirements for the coating material. For example, side-emitting fiber optics (SEFOs) with a protective transparent casing can be applied to an injection-molded part to create a powerful, flat light element.

- Functionalizing technologies (iwu.fraunhofer.de)

- WEAM - Wire Encapsulating Additive Manufacturing (iwu.fraunhofer.de)

- FEAM - Fiber Encapsulating Additive Manufacturing (iwu.fraunhofer.de)

- AuCA - Automated Cable Assembly (iwu.fraunhofer.de)

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology