Press information

Here you can find our press information and high-resolution images for your editorial reporting. Publications about the Fraunhofer IWU are explicity desired.

Here you can find our press information and high-resolution images for your editorial reporting. Publications about the Fraunhofer IWU are explicity desired.

On November 4, an Ariane 6 rocket successfully carried the Earth observation satellite Sentinel-1D into orbit. Looking ahead, the new launch vehicle is expected to lift off at short intervals, allowing Europe to remain a key player in space research. A perfectly synchronized production network that manufactures components with the highest precision is essential for aerospace applications. Sensors can play a crucial role here—from physical traceability of parts to condition monitoring and quality management. Advanced sensor technology also helps make energy consumption in production more manageable.

more info

This year’s exhibits at Formnext focuse on materials particularly suited for aerospace applications but so far rarely used in LPBF (Laser Powder Bed Fusion) processes, as well as on printed components with integrated electrical functions. But the booth itself is also a highlight: It is fully 3D-printed, using elements made from biodegradable plastic and recyclable polypropylene (PP). After the event, the modular system will not be discarded. The high-quality exhibition furniture will be reassembled and repurposed for presentation purposes at Fraunhofer IWU.

more info

Under the leadership of Fraunhofer IWU, 28 partners from academia and industry are working to reduce the carbon footprint of electric vehicles by at least 25 percent and significantly increase the share of recycled materials. After a year and a half, the European research project ZEvRA (Zero Emission electric Vehicles enabled by haRmonised circulArity) can already report positive interim results. Examples include vehicle roofs that can demonstrably be converted cost-effectively into new vehicle components, and many aluminum components can be nearly fully made from recycled (secondary) aluminum. Plastics and composite materials with up to 97 percent recycled content have already been processed into the first demonstration parts.

more info

At Formnext 2025, the Fraunhofer IWU will present the latest generation of the WEAM tool (Wire Encapsulating Additive Manufacturing). This technology opens up entirely new possibilities: components can be manufactured with a wide range of integrated electrical functions, offering significantly better performance for sensing and load-bearing tasks compared to paste-, ink-, or powder-based printing methods. The key lies in the use of standard wires and cables, which, due to their homogeneous alloy and constant conductor cross-section, ensure perfect electrical properties.

more info

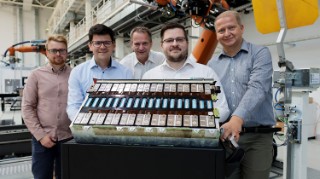

Battery housings in electric vehicles must be impact-resistant, absorb crash energy, protect against short circuits, and be heat-resistant. Efficient heat dissipation is essential, but cells also need protection from excessive cooling. The housing must resist damage from stones and salt, fit the vehicle’s underbody, add rigidity, and, being lightweight, help increase range. Aluminum foam satisfies these requirements.

more info

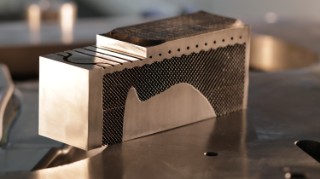

Additive manufacturing, particularly the Laser Powder Bed Fusion (LPBF) process, offers new possibilities in toolmaking due to its considerable design freedom. Fraunhofer IWU is unlocking this potential in two research projects, "AdTopoTool" and "EWAM." The goal is to accelerate the development and production of more efficient tools for sheet metal forming and injection molding. This also improves the quality of the components, which can be produced more efficiently using such tools.

more info

The Franco-German AI initiative is part of a long-term strategic partnership. Since the signing of the Aachen Treaty in 2019, both countries have intensified their cooperation in this area. Specifically, the collaboration between the German Federal Ministry for Economic Affairs and the French Ministry for Economy and Digital Sovereignty pursues a shared goal: to strengthen European competitiveness, drive green and digital technologies, and ensure technological leadership. GreenBotAI is a key example—enhancing the robustness of robotic automation.

more info

After years of use, many traction batteries still have a residual capacity of between 70 and 80 percent. While this may be too little for further use in vehicles, some cells could still serve well in large storage systems for households, businesses, or utility providers. Shredding used modules or entire high-voltage storage systems would thus waste valuable resources. By repairing and remanufacturing these batteries, not only can precious resources be preserved, but the lifespan of the components can also be extended. Cells that have been specifically refurbished and repurposed for new applications can be ready for long-term use again. Dr. Rico Schmerler and his team at Fraunhofer IWU, in collaboration with EDAG Production Solutions, are investigating how components and cells from traction batteries can be extracted efficiently and cost-effectively in a new project.

more info

Hand mobility is often impaired after tendon injuries or as a result of strokes. In therapy, exoskeletons increasingly serve to support recovery. These devices fit over the hand like a second skeleton and can assist with controlled movements of the wrist and fingers. However, only products specifically tailored to an individual hand—and meeting key requirements such as low weight and compact design—offer a real chance of therapeutic success. After all, a support and motion aid that hinders more than it helps will likely end up collecting dust on a shelf.

more info

Hollow embossing is an efficient, resource-saving forming process that offers clear advantages over conventional methods, especially when producing complex hollow structures. At EuroBLECH 2024, Fraunhofer IWU introduced the BPPflexROLL—a highly efficient system for manufacturing bipolar plates (BPP) for fuel cells or heat exchanger plates. Now, the new flexROLLmax expands the production spectrum to include large-format components such as electrolyzer plates. As the “big sister” of the BPPflexROLL, it opens up new segments of the sheet metal sector for embossing components. It handles sheet thicknesses up to 0.5 mm and component sizes up to 1.2 meters in edge length with ease.

more info