Premiere at the Fraunhofer IWU | B2B Production Forum on Sept. 16 - 17 in Chemnitz

Leading the Way in Industrial-Scale Hollow Embossing: Fraunhofer IWU Presents flexROLLmax for Larger Components and Material Thicknesses

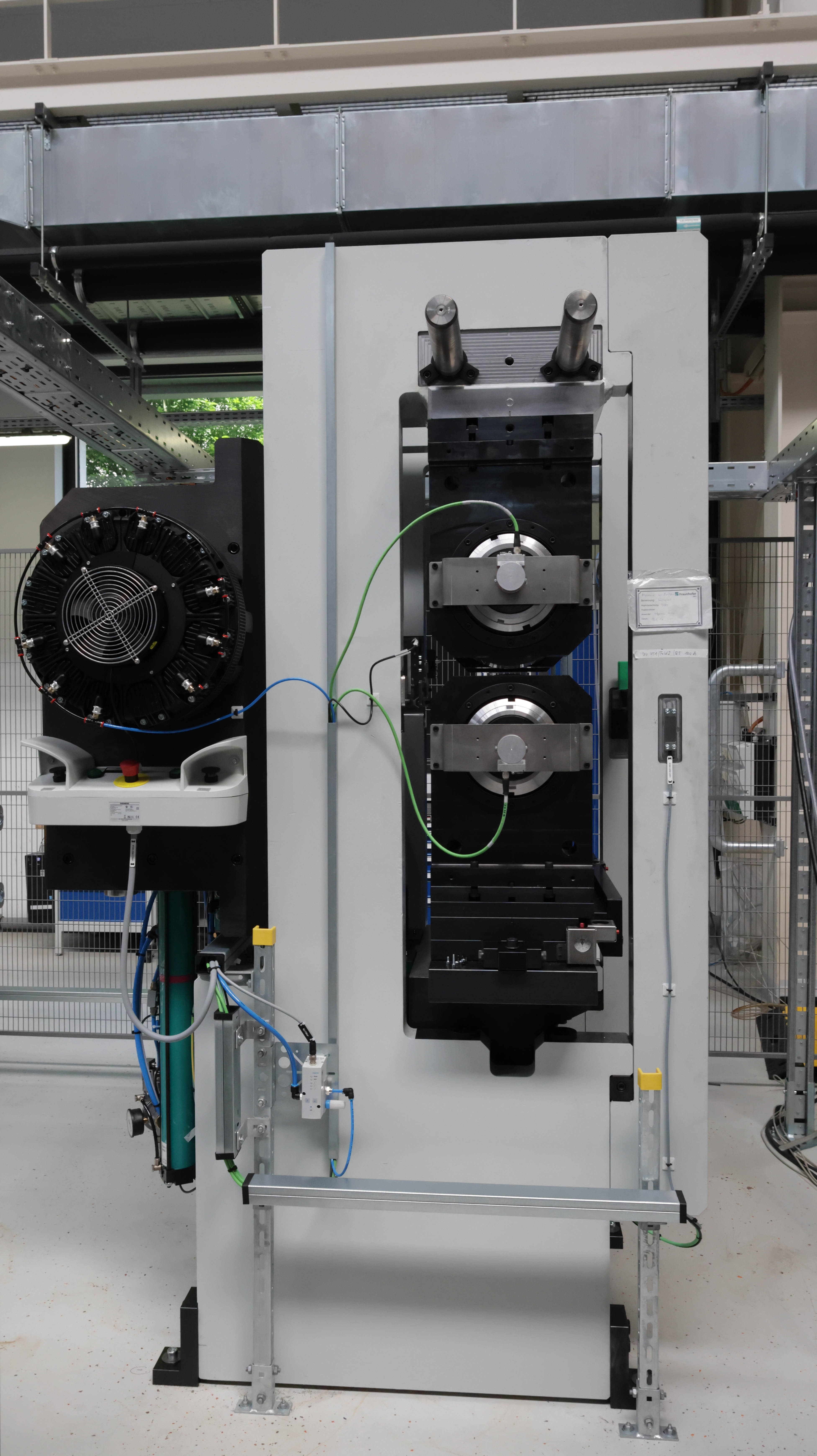

Hollow embossing is an efficient, resource-saving forming process that offers clear advantages over conventional methods, especially when producing complex hollow structures. At EuroBLECH 2024, Fraunhofer IWU introduced the BPPflexROLL—a highly efficient system for manufacturing bipolar plates (BPP) for fuel cells or heat exchanger plates. Now, the new flexROLLmax expands the production spectrum to include large-format components such as electrolyzer plates. As the “big sister” of the BPPflexROLL, it opens up new segments of the sheet metal sector for embossing components. It handles sheet thicknesses up to 0.5 mm and component sizes up to 1.2 meters in edge length with ease.

The flexROLLmax complements the existing machine portfolio of the Fraunhofer IWU, which already boasts unique expertise in processes and machinery for embossing reliefs on metallic surfaces. In collaboration with interested partners, the Chemnitz-based research institute aims to extend hollow embossing to entirely new product categories. Structural and functional components for household and building technology, as well as the electrical industry, are just a few examples of potential applications. Key Advantages of Hollow Embossing are:

High Production Rates and Cost Efficiency

Unlike discontinuous processes such as classical hollow embossing or high-pressure sheet metal forming, where one press stroke produces a part, followed by a pause, hollow embossing is a continuous process using a pair of rollers. This characteristic enables a significant increase in output and creates economies of scale. Ultimately, this results in much lower production costs per part, supporting the market viability of industrial products.

Reduced Process Forces and Compact Machine Design

Thanks to its incremental nature (forming in small, successive steps), hollow embossing dramatically reduces process forces by a factor of approximately 10 compared to conventional methods. Lower forces mean smaller, lighter, and more cost-effective machine components. In turn, more compact machine components mean reduced investment costs, space requirements, and energy consumption.

Flexibility and Adaptability

Both the BPPflexROLL and the flexROLLmax are modular and flexible in design, making them easy to relocate and reconfigure; the number of roller sets required depends on the specific geometry of the component. These characteristics increase production flexibility, as different geometries will be producible on the same machine with minimal changeover.

Potential for Process Monitoring and Quality Control

Fraunhofer IWU is working to evolve hollow embossing into a “cognitive forming process.” By integrating sensors and intelligent algorithms, it is possible to monitor and ensure part quality during the forming process, thereby minimizing scrap.

flexROLLmax Premieres at the Fraunhofer IWU | B2B Production Forum

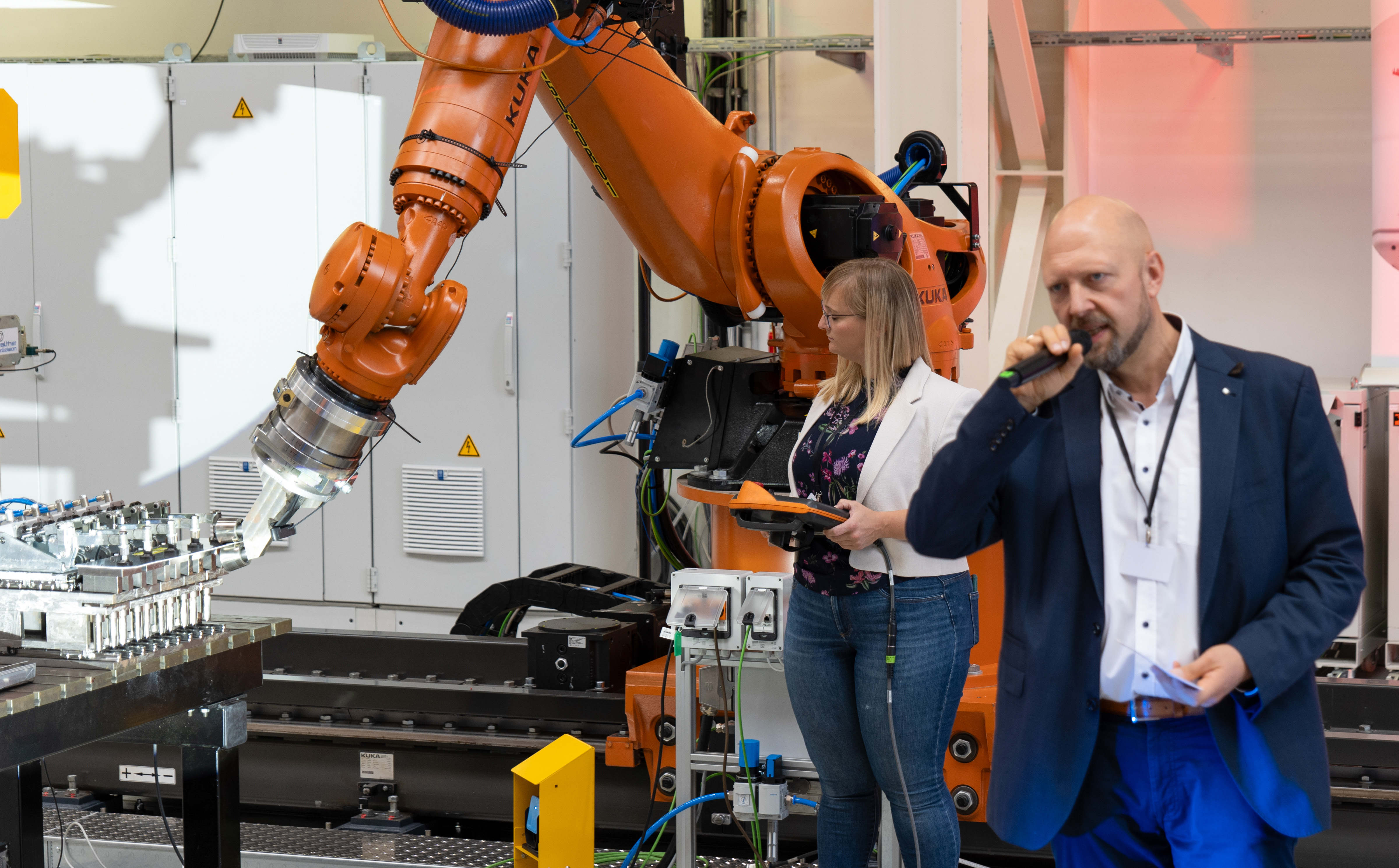

Fraunhofer IWU and fourteen partners will host the B2B Production Forum in Chemnitz on September 16 - 17, 2025, bringing together researchers and industry professionals. The flexROLLmax will be a featured highlight in the section “Profile Processing in Sheet and Solid Forming.” Other key topics in keynote talks, workshops, and live demonstrations include:

- Finishing and Grinding: Development trends and new processes

- Digitalization in Manufacturing: Seamless process integration, cloud services, and industrial service solutions, including process monitoring in metal-cutting machines and "Hands-On Shopfloor Digitalization“

- Hydrogen System Production: Latest manufacturing technologies, system design, and applications

- Precision Toolmaking and Functional Surfaces: Subtractive processes for toolmaking and the design of functional surfaces

- CNC Robotics: Easy integration of robots into manufacturing processes

- Automated Assembly and Disassembly: Efficient design of assembly and disassembly workflow

- 3D Printing: Speed and precision in industrial plastic and metal additive manufacturing

- Batix New Work: Digitalization in production technology

More information and registration Fraunhofer IWU Open House | B2B Production Forum (in German)

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology