Press information

Here you can find our press information and high-resolution images for your editorial reporting. Publications about the Fraunhofer IWU are explicity desired.

Here you can find our press information and high-resolution images for your editorial reporting. Publications about the Fraunhofer IWU are explicity desired.

On November 4, an Ariane 6 rocket successfully carried the Earth observation satellite Sentinel-1D into orbit. Looking ahead, the new launch vehicle is expected to lift off at short intervals, allowing Europe to remain a key player in space research. A perfectly synchronized production network that manufactures components with the highest precision is essential for aerospace applications. Sensors can play a crucial role here—from physical traceability of parts to condition monitoring and quality management. Advanced sensor technology also helps make energy consumption in production more manageable.

more info

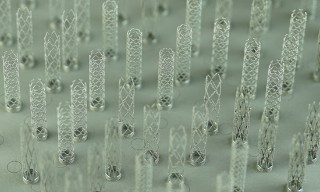

This year’s exhibits at Formnext focuse on materials particularly suited for aerospace applications but so far rarely used in LPBF (Laser Powder Bed Fusion) processes, as well as on printed components with integrated electrical functions. But the booth itself is also a highlight: It is fully 3D-printed, using elements made from biodegradable plastic and recyclable polypropylene (PP). After the event, the modular system will not be discarded. The high-quality exhibition furniture will be reassembled and repurposed for presentation purposes at Fraunhofer IWU.

more info

Under the leadership of Fraunhofer IWU, 28 partners from academia and industry are working to reduce the carbon footprint of electric vehicles by at least 25 percent and significantly increase the share of recycled materials. After a year and a half, the European research project ZEvRA (Zero Emission electric Vehicles enabled by haRmonised circulArity) can already report positive interim results. Examples include vehicle roofs that can demonstrably be converted cost-effectively into new vehicle components, and many aluminum components can be nearly fully made from recycled (secondary) aluminum. Plastics and composite materials with up to 97 percent recycled content have already been processed into the first demonstration parts.

more info

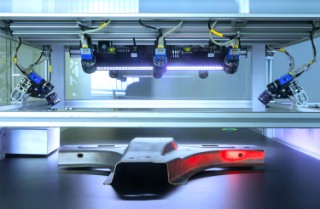

At Formnext 2025, the Fraunhofer IWU will present the latest generation of the WEAM tool (Wire Encapsulating Additive Manufacturing). This technology opens up entirely new possibilities: components can be manufactured with a wide range of integrated electrical functions, offering significantly better performance for sensing and load-bearing tasks compared to paste-, ink-, or powder-based printing methods. The key lies in the use of standard wires and cables, which, due to their homogeneous alloy and constant conductor cross-section, ensure perfect electrical properties.

more info

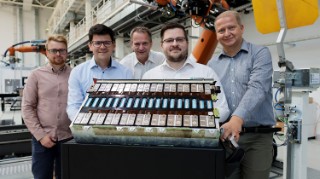

Battery housings in electric vehicles must be impact-resistant, absorb crash energy, protect against short circuits, and be heat-resistant. Efficient heat dissipation is essential, but cells also need protection from excessive cooling. The housing must resist damage from stones and salt, fit the vehicle’s underbody, add rigidity, and, being lightweight, help increase range. Aluminum foam satisfies these requirements.

more info

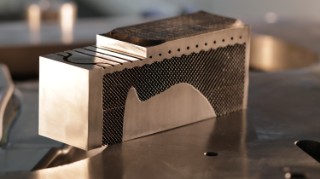

Additive manufacturing, particularly the Laser Powder Bed Fusion (LPBF) process, offers new possibilities in toolmaking due to its considerable design freedom. Fraunhofer IWU is unlocking this potential in two research projects, "AdTopoTool" and "EWAM." The goal is to accelerate the development and production of more efficient tools for sheet metal forming and injection molding. This also improves the quality of the components, which can be produced more efficiently using such tools.

more info

The Franco-German AI initiative is part of a long-term strategic partnership. Since the signing of the Aachen Treaty in 2019, both countries have intensified their cooperation in this area. Specifically, the collaboration between the German Federal Ministry for Economic Affairs and the French Ministry for Economy and Digital Sovereignty pursues a shared goal: to strengthen European competitiveness, drive green and digital technologies, and ensure technological leadership. GreenBotAI is a key example—enhancing the robustness of robotic automation.

more info

After years of use, many traction batteries still have a residual capacity of between 70 and 80 percent. While this may be too little for further use in vehicles, some cells could still serve well in large storage systems for households, businesses, or utility providers. Shredding used modules or entire high-voltage storage systems would thus waste valuable resources. By repairing and remanufacturing these batteries, not only can precious resources be preserved, but the lifespan of the components can also be extended. Cells that have been specifically refurbished and repurposed for new applications can be ready for long-term use again. Dr. Rico Schmerler and his team at Fraunhofer IWU, in collaboration with EDAG Production Solutions, are investigating how components and cells from traction batteries can be extracted efficiently and cost-effectively in a new project.

more info

Hand mobility is often impaired after tendon injuries or as a result of strokes. In therapy, exoskeletons increasingly serve to support recovery. These devices fit over the hand like a second skeleton and can assist with controlled movements of the wrist and fingers. However, only products specifically tailored to an individual hand—and meeting key requirements such as low weight and compact design—offer a real chance of therapeutic success. After all, a support and motion aid that hinders more than it helps will likely end up collecting dust on a shelf.

more info

Hollow embossing is an efficient, resource-saving forming process that offers clear advantages over conventional methods, especially when producing complex hollow structures. At EuroBLECH 2024, Fraunhofer IWU introduced the BPPflexROLL—a highly efficient system for manufacturing bipolar plates (BPP) for fuel cells or heat exchanger plates. Now, the new flexROLLmax expands the production spectrum to include large-format components such as electrolyzer plates. As the “big sister” of the BPPflexROLL, it opens up new segments of the sheet metal sector for embossing components. It handles sheet thicknesses up to 0.5 mm and component sizes up to 1.2 meters in edge length with ease.

more info

Fuel cells convert hydrogen into electrical energy, providing a locally CO₂-free power source for heavy-duty trucks, rail vehicles, ships, automobiles, and aircraft. Starting in October 2025, Fraunhofer IWU will be able to thoroughly test fuel cells and fuel cell systems on behalf of its industrial clients and project partners. The purpose of such testing is to characterize and evaluate performance, durability, reliability, and other critical properties under various operating conditions. Also under scrutiny will be essential components like cooling units, water separators, pumps, sensors, humidifiers, and heat exchangers. The team led by Dr. Carmen Meuser has a clear goal: to accelerate the ramp-up of fuel cell manufacturing.

more info

Trade show debut for the start-up Botfellows GmbH: Since September 2024, the spin-off from Fraunhofer IWU has been advancing the development of innovative robotics software as an independent company. The focus is on the intelligent solution Botfellows Dynamic Safety, which is directly integrated into robot control systems and replaces physically fenced-off workspaces between humans and (industrial) robots with dynamic safety zones. At automatica, visitors can experience a live demonstration featuring an industrial robot operating without safety fences, thus ensuring outstanding productivity.

more info

The first relatively compact, transportable quantum computer in Saxony – and one of the first in the world to operate at room temperature – has been up and running since June 11 at Fraunhofer IWU’s Dresden institute. The IWU will primarily use the new 4-qubit quantum computer system to further develop Industry 4.0 solutions aimed at self-regulating, human-learning (cognitive) production systems. Thanks to the institute’s close ties to manufacturing sectors such as automotive, aerospace, and mechanical and plant engineering, industrial partners will also stand to benefit.

more info

Focusing on self-optimizing systems, flexible and adaptable factories, human involvement in production, and agile process chains, the 17 institutes of the Fraunhofer autoMOBILproduction Alliance are strong industrial partners. At automatica, the Alliance will present clever automation solutions, including quality assurance, hands-on VR and AR applications, and highly robust sensor systems for process control.

more info

The Chemnitz Research Institute presents the ESiP Analyzer – an analysis tool for energy storage applications in production (ESiP). The tool enables technical and economic evaluation of potential uses for energy storage systems in factories. Its goal is to identify energy storage opportunities with minimal effort and to simplify the design and integration of storage solutions. The ESiP Analyzer focuses on two key areas: reducing power peaks at both the machine and factory levels, and enabling intermediate storage of renewable energy.

more info

Passenger aircraft doors are still primarily manufactured by hand. A particularly time-consuming aspect is assembling the door structures using screws and rivets. Numerous intermediate steps are required to prevent direct contact between different materials—which would otherwise lead to corrosion. However, replacing aluminum, titanium, and thermosets with primarily thermoplastic carbon fiber composites (CFRP), which can be welded together automatically without separating layers, makes the process much faster. Manufacturing time for the door structure drops from 110 hours to just 4. A research project by Fraunhofer IWU, Fraunhofer LBF, Trelleborg, and Airbus Helicopters has shown this clearly.

more info

Fraunhofer IWU and the TU Bergakademie Freiberg have achieved a breakthrough in steel casting technology. Their development of a cold-formable, copper-alloyed austenitic steel cast with TRIP/TWIP properties marks a milestone in material science. It also opens up entirely new perspectives for safety-critical applications. The new alloy offers an unprecedented combination of strength and ductility: it is highly load-bearing and can still undergo plastic deformation.

more info

Who does not know the struggle? Whether several hundred pages of car manuals or extensive legal texts, picking out crucial information is often time-consuming. And will you come across all the relevant entries? A glossary that does not know the search term and countless cross-references make things even more difficult. Such trouble could soon be a thing of the past: A team at Fraunhofer IWU is now helping an AI solution by "feeding" it with extensive technical and legal texts. The team prepares the external input so that search queries (prompts) lead to precise and exhaustive information. Retrieval Augmented Generation (RAG) makes this possible.

more info

To survive in global competition over the long term, companies have to be efficient, cost-effective and use resources wisely in their production operations. AI-based monitoring and control of production based on ECC4P (Edge Cloud Continuum for Production) offers medium-sized businesses customized solutions with comprehensive data security from a single source. The research team will be presenting their solutions at the joint Fraunhofer booth at this year’s Hannover Messe trade show.

more info

More specifically, they store electricity generated from solar and wind power in the form of hydrogen (electrolysis) – for extended periods if needed. "Storable" green electricity would be a significant advancement: Today, unused electricity is sometimes given away to neighboring countries on weekends to prevent overloads in the power grid. Conversely, as autonomous energy networks in a compact format, microgrids bridge periods of low energy production, known as "dark doldrums," when there is no wind or sunshine. Fuel cells in the grid then convert the stored hydrogen back into electricity. Thus, these grids are ideally suited for local energy networks and can fit into offshore containers.

more info

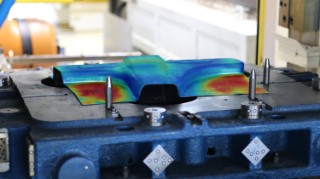

YQuality control in hot forming can often only begin when the workpiece has cooled down. Conventional optical quality assurance methods are limited when dealing with hot parts; as the temperature of the workpiece rises, the blurriness in determining its geometry increases. This finding leads to high scrap rates and unnecessary costs due to process-related quality defects. The GreenHiTemp project offers a promising solution with thermal imaging, enabling reliable predictions during the process instead of relying on post-production checks.

more info

You can find them in many household appliances, building technology, and countless pipe and hydraulic lines: small, cylindrical parts manufactured through deep drawing processes. The material is under strain during shaping: Potential consequences are unwanted thinning, surface damage, or cracks. The solution is ultrasonic vibrations - these reduce friction significantly within the material and in contact with the tools. In the VibroDraw process, Fraunhofer IWU, in collaboration with MARK Metallwarenfabrik GmbH and DEVAD GmbH, has successfully integrated ultrasonic vibrations into industrially relevant deep drawing processes with cycle rates of up to 500 strokes per minute.

more info

The facade defines the first impression of a building. Is it worth taking a closer look? Are there elements that set it apart from its (built) surroundings? Even small design accents can make the difference between 'attractive' and 'does not appeal to me.' The Fraunhofer IWU now offers a solution for architects and builders who seek equally appealing and cost-effective options: striking facade elements with reliefs that have nearly limitless shape and color possibilities and do not require expensive forming tools.

more info

Fraunhofer Institutes for Machine Tools and Forming Technology IWU and for Manufacturing Technology and Advanced Materials Research IFAM have made a breakthrough in materials research. The composite material HoverLIGHT sets new standards for the construction of machine tools: by combining aluminum foam and particle-filled hollow spheres, HoverLIGHT achieves an unprecedented combination of lightness, stiffness, and vibration damping. In a joint project with an industrial partner, the two Fraunhofer Institutes have demonstrated for the first time that HoverLIGHT can dampen vibrations in series machines by a factor of 3. All this comes with a weight saving of 20% compared to the original assembly.

more info

Present-day medical procedures burden patients as little as possible. Surgeons should avoid damaging tissue on the precisely defined path to the site of surgical intervention, which is especially true for operations on sensitive organs such as the brain. For certain brain tumors, surgeons choose the gentlest access to the brain – through the nose. Here, state-of-the-art technology comes into play: it visualizes what the doctor cannot see from the outside. Precise, high-resolution image data of the patient, as provided by magnetic resonance imaging (MRI), serves as a "map" for navigation; the operating surgeon sees this image data as a projection in data glasses. A central component, the handpiece for attaching the surgical instruments, is being developed and 3D-printed at the Fraunhofer IWU.

more info

For 15 years now, researchers at the Dresden branch of the Fraunhofer IWU have been working on the additive technology LPBF (Laser Powder Bed Fusion), in which a laser beam melts metallic powder layer by layer locally at the points where the component grows. In this process, the entire physical and digital process chain must be mastered, to create a functioning component from powder. Adapted scanning strategies that define the sequence, length, alignment, and spacing of the laser paths are a promising approach for LPBF. They help to produce components that are more delicate, homogeneous, dimensionally accurate, and with improved surfaces.

more info

At the new SEAM Research Center, researchers aim to unlock the potential of Screw Extrusion Additive Manufacturing (SEAM) even further. Its centerpiece is Epic3D, a newly developed portal printer that enables the production of large-format plastic components. The continuous deposition process and stiffening structures ensure durable parts, making the technology ideal for producing custom-designed facade elements and other weather-resistant products for the construction industry.

more info

Wire or Fiber Encapsulating Additive Manufacturing (WEAM/FEAM) could significantly simplify the industrial production of components that require the integration of complex yet compact wiring, sensors, actuators, or lighting systems – by directly printing these components into the parts. The FEAM process uses glass fibers instead of wires, which are coated with a polymer and applied to any substrate without affecting its optical properties. This technology enables the creation of customizable lighting elements, sensors, or data conductors on 2D or 3D surfaces. A new development at Fraunhofer IWU: the Automated Cable Assembly (AuCA). Conventional robotics fails to produce and automatically lay flexible cable bundles in vehicles; AuCA, however, manufactures the wiring using a robot-guided way on a component and fixes it with a polymer.

more info

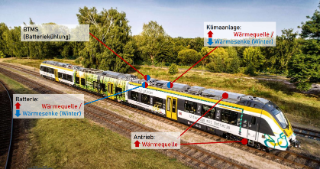

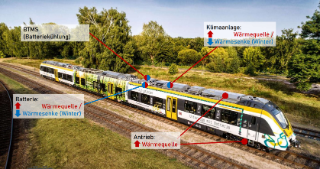

The drive system of a rail vehicle is the largest energy consumer in operation, followed by the systems for temperature management of the passenger compartment and the drive system—regardless of the type of train propulsion. Batteries or fuel cells must be maintained at an optimal operating temperature in electrically powered trains without energy supply via overhead lines or third rails. Many rail operators are considering such trains for the nearly 40 percent of non-electrified tracks in Germany. The overall energy consumption in these trains significantly impacts range and potential operating times.

more info

A book of success stories that inspires young women to take up mathematics, computer science, natural sciences and technology (STEM) with examples from science? That alone would not be enough for the Fraunhofer researchers Manja Mai-Ly Pfaff-Kastner, Esther Packullat, Dr. Isabel Michel, Lisa Martha Kunkel and Prof. Dr. Tanja Manuela Kneiske. »Forscherinnen im Fokus – Wir schaffen Veränderung« (Female Researchers in Focus – We Are Creating Change) wants more: to look at the world of artificial intelligence and simulation through the eyes of extraordinary female scientists and tell exciting, very personal stories in the process. ›Frau N. Hofer‹, as it is known for short, traces a variety of (life) paths in science and, in doing so, »incidentally« draws attention to fascinating opportunities for shaping the future, particularly in applied research.

more info