From grip to print: automated cable laying rethought

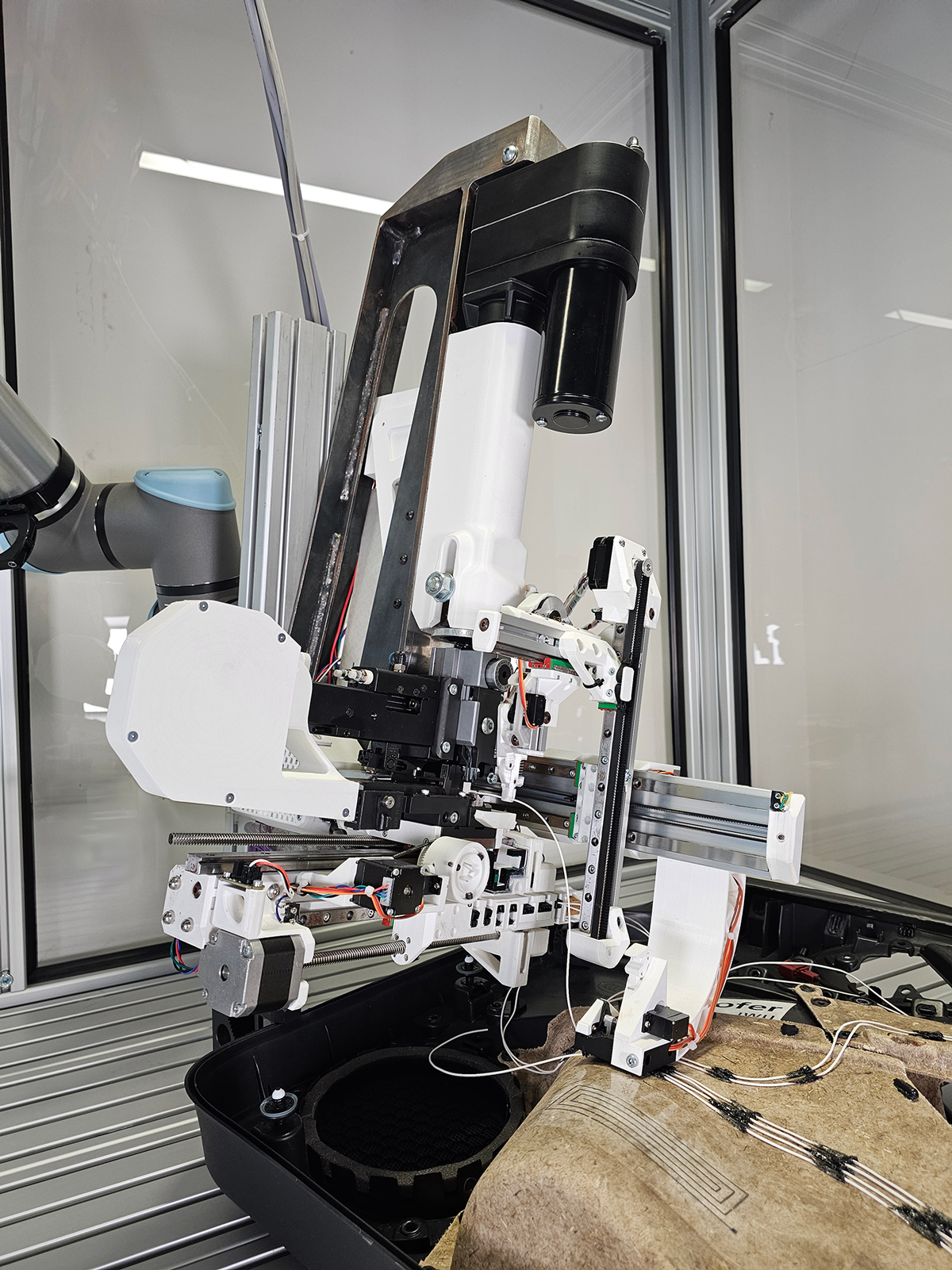

Handling and automated assembly of a wiring harness consisting of multiple cables with different lengths, cross-sections, and end contacts is extremely difficult for a robotic system to manage. For this reason, solutions typically involve a significant amount of cameras, software, and processing. In the AuCA system, cable laying has been completely rethought and combined with 3D printing technology, so that the flexible cables no longer need to be "gripped" but are laid from an endless reservoir

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology