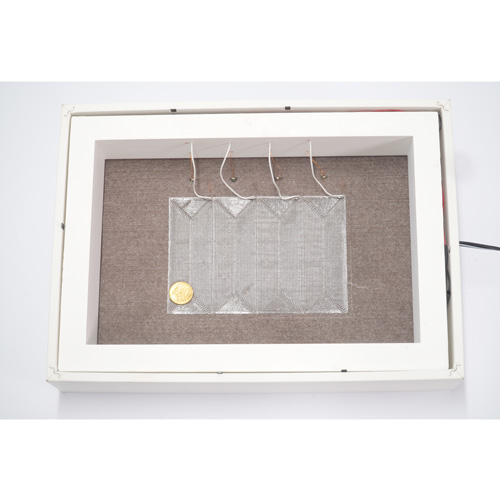

Printed proximity sensors on wood veneer – Shy Tech for vehicle interiors or home furnishings

Challenge

If components are to perceive their environment, it means that additional components must be integrated into the part. This usually leads to the need for planning and assembling additional parts, which can disrupt the original function of the component in the worst case. The integration of sensors can help implement this close to the point of action without significantly affecting the component, but it often requires manual processes. For these reasons, we are working on methods for the automated integration of sensors for stress, temperature, proximity, and touch. These should enable individual components to be manufactured more intelligently, compactly, and lightly.

Solution

To achieve repeatable integration, automated methods must be applied. This process must also be capable of implementing various types of sensors. Since many sensor principles can be traced back to functional wires, integration can be carried out using the WEAM process. Sensors can be created directly where the most relevant sensor response is expected through additive processes. Additionally, the high material freedom allows sensors to be fixed in polymer materials using an identical polymer, resulting in no mechanical influences.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology