Small but exact

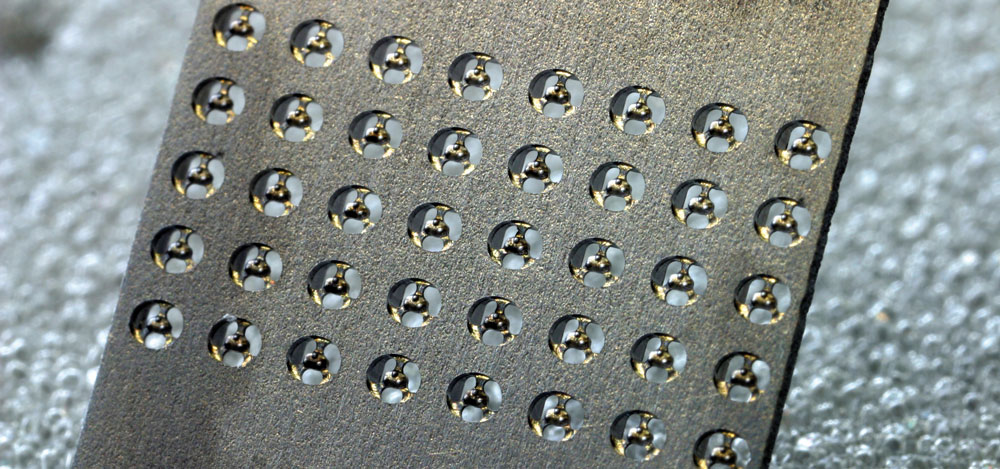

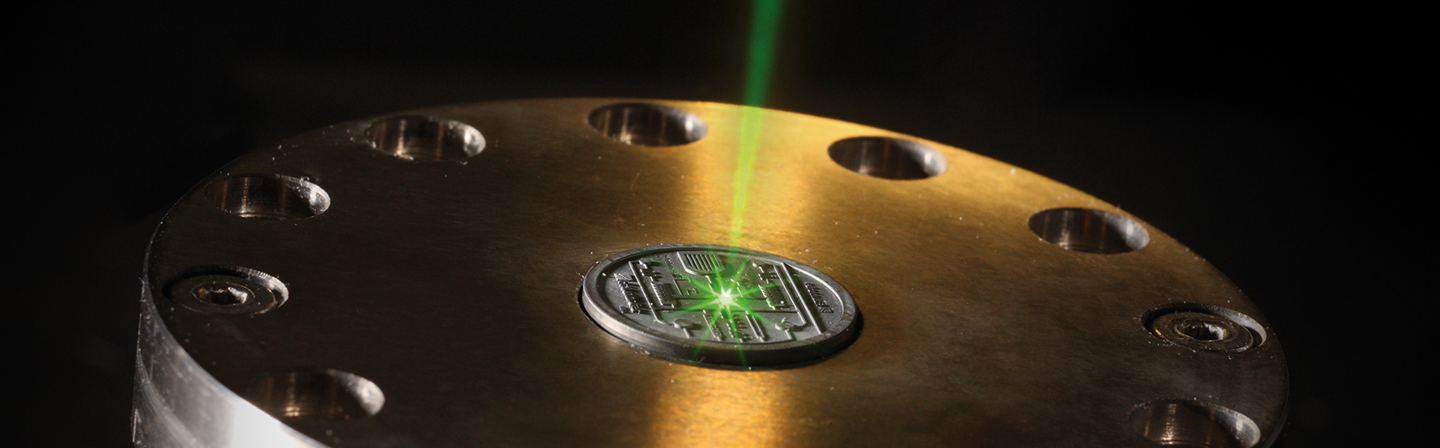

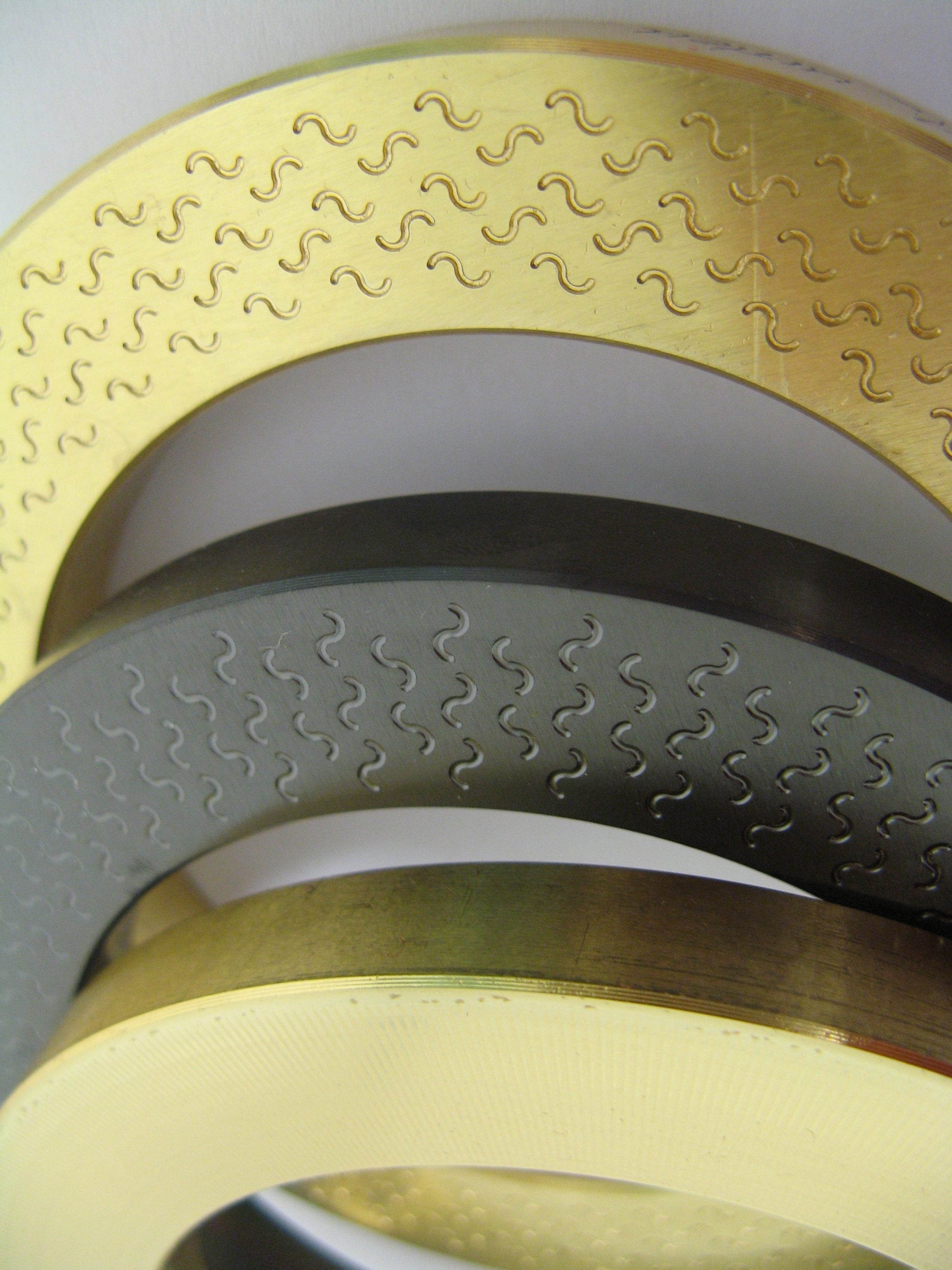

Miniaturization of components and functional elements opens up new potentials in various areas of daily life. In medical engineering, lost body functions can be restored by miniaturized implants, and in chemical applications, using microreactors results in safer chemical reactions with improved control and a lower amount of reagents required. Furthermore, miniaturization of injection holes in fuel injection systems allows for environmentally friendly combustion engines with low consumption levels.

A considerable potential of lightweight construction opens up as part dimensions become smaller. Thus, materials and energy can be saved or other effects and functional principles can be used that are generally not associated with conventional engineering. Changing dimensions of parts and functional elements from the millimeter to the micrometer range significantly alters the ratio of part surface to part volume. Consequently, more intensive and dynamic interaction is possible between the microcomponents and their environment.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology