More efficiency in component properties

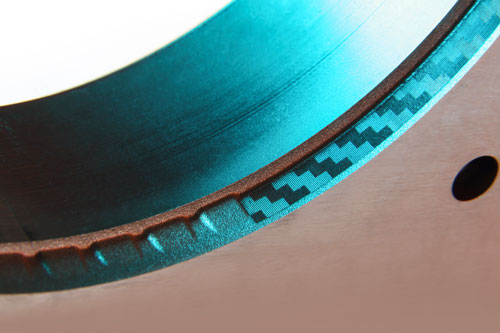

Finishing processes or downstream structuring processes can modify microstructures of boundary layers and surface profiles, which provides surfaces with specific functions. The focus lies on sliding properties, wetting behavior or biocompatibility of applications in the automotive industry, in tool making and medical engineering.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology