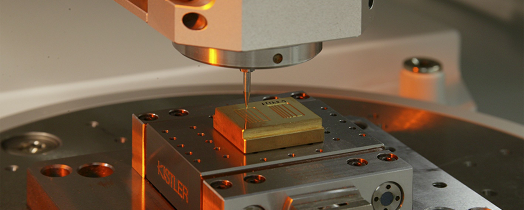

Flexible microstructuring by micro cutting

Micro cutting technologies enable manufacturing of the smallest structural details in dimensions of up to approx. 30 µm. Applications include die and mold making as well as manufacturing of microstructural components as prototypes. Micro cutting can be used very flexibly for a large variety of geometrical shapes and a wide range of materials, even hard machining is possible up to 65HRC.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology