Pulling together - not just an approach, it's our passion

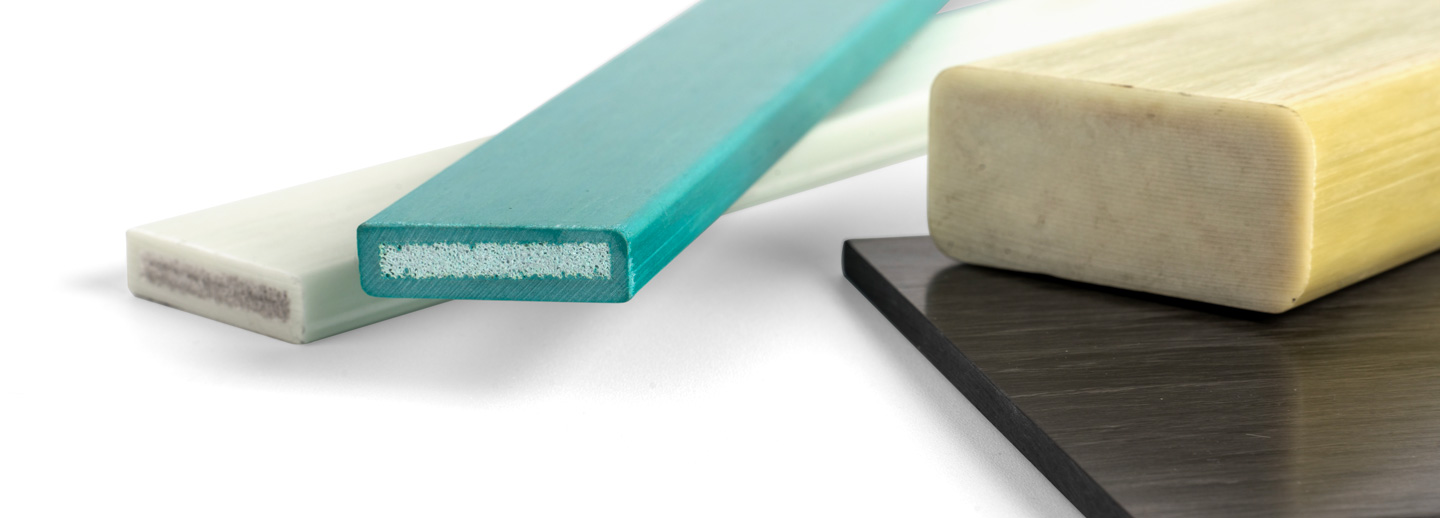

Continuous fibre-reinforced plastic profiles can be produced efficiently and economically using the pultrusion process, also known as the strand drawing process. Starting with dry fibres or textile semi-finished products, these are impregnated with a matrix system in the next process step, which then cures in a heated mould to form a solid profile. Thanks to their customised reinforcement structure, they can withstand high loads. At the same time, they are very lightweight and therefore have enormous potential for lightweight construction. In addition to the production of straight profiles, the Fraunhofer IWU can also manufacture constantly curved structures. Various cross-sectional geometries can be realised, from solid profiles to complex multi-chamber hollow structures. Due to the continuous process sequence and the high pull-off speeds of up to 2,500 millimetres per minute, the process is very economical and predestined for medium and large-scale production.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology