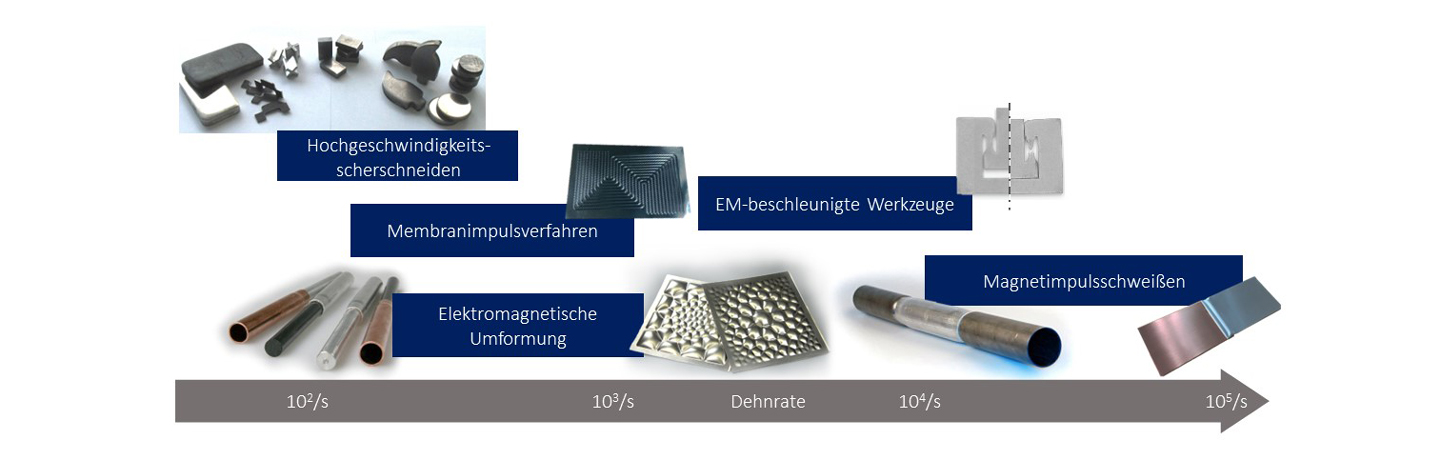

Leveraging speed effects in production technology offers significant technological and economic advantages. Many materials, such as aluminum, magnesium, and titanium alloys, as well as certain steels and copper alloys, exhibit enhanced formability at high strain rates. This effect is utilized in high-speed forming, allowing for the creation of geometries—such as sharp-edged details—that are difficult or impossible to achieve with conventional methods, often requiring multi-stage processes and heat treatments. High-speed forming typically occurs without external heat input, making it an energy-efficient alternative to hot forming. Additionally, defects such as wrinkles, necking, and springback can be reduced compared to conventional forming processes.

High-speed forming, often referred to as impulse forming, can be used not only for shaping but also for cutting and joining in forming technology. The duration of the actual forming process in impulse forming ranges from microseconds to a few milliseconds. The achievable cycle time is therefore largely determined by secondary process times, such as component handling or charging the energy storage system. The latter is necessary to make the required energy available quickly. For industrial applications, electrical (capacitive) or mechanical (e.g., hydraulic) energy storage systems are particularly suitable. Energy transfer to the workpiece can be mechanical, through accelerated tools or working media (e.g., membrane impulse methods), or electromechanical, based on active energy or Lorentz forces (electromagnetic forming). The force acts only for a very short duration, allowing for the use of simple clamping devices instead of costly press technology.

Advantages of the Process

- Forming complex geometries from materials that are conventionally difficult to form

- Reduced wrinkles, necking, and springback compared to conventional forming processes

- No costly press technology required

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology