High-Speed Shear Cutting

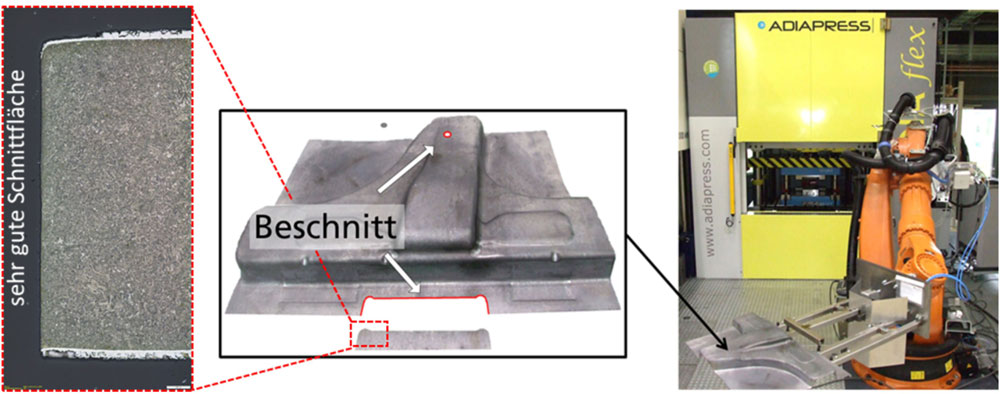

In high-speed shear cutting (HSSC), there are fundamental differences compared to conventional cutting, especially regarding the different process phases. The punch impacts the sheet at high speed, and after elastic deformation, the sheet material in the area between the cutting edges of the die and punch is rapidly plastically deformed. In HSSC, complete sliding of the punch through the punch grid is generally not required, so the component can be ejected due to kinetic energy even if the punch is stopped at approximately 1/3 of the sheet thickness. Depending on the material and process parameters, local strain rates increase due to the localization of plastic deformation. Localization is favored by high strain rates, low strain rate sensitivity, and low thermal conductivity. Due to high plastic deformation and the resulting conversion of deformation energy into heat, as well as friction combined with short process time and low heat conduction, high temperatures can occur in the localization zone. This can lead to plastic instabilities, such as the formation of an (adiabatic) shear band. The ratio of cutting forces in HSSC and conventional shear cutting depends on the material. The appearance of the cut surfaces is also significantly influenced by the increased process speeds. Only minimal edge draw-in, virtually no smooth cut, and very little burr are produced. The separation surface in HSSC is thus almost entirely characterized by the fracture surface. The fracture surface, in turn, exhibits a fracture angle close to 90° and low roughness, unlike conventional cutting. In addition to high straightness in HSSC, the formation of adiabatic shear bands allows for the targeted influence of local microstructures, resulting in exceptional (surface) property combinations. This can enable the use of surfaces produced by HSSC as functional surfaces.

HSSC is suitable for a wide range of materials. For very ductile materials, the draw-in is significantly reduced compared to conventional shear cutting. For very hard or hardened materials, HSSC enables general trimming with excellent cut surface properties due to high local heat and associated local thermal softening. Sheet thicknesses from 0.2 to 10 mm can be cut at the Fraunhofer IWU.

Insight into the Project

Key data for the project

Duration

until 2026

Coordination

DFG - FOR5380

Project partners

TU Chemnitz (WOT, LWW), TU Dortmund (IUL), TU München (utg), Fraunhofer IWM

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology