Efficient Accuracy Prediction and Monitoring for Machining (AccuMonit)

Precision machining plays a significant role in the manufacturing industry, such as CNC machining, additive manufacturing, etc. Since high accuracy is always accompanied by higher efforts and resource requirements, companies often face the dilemma of either achieving high accuracy with low productivity or pursuing high productivity with a high risk of scrap, especially in small-batch production. This risk originates from the behaviour of the machine, the tool, and the workpiece during machining. The information about the workpiece accuracy during machining enables the user to react quickly and effectively in case of impending out-of-tolerance machining. Thus, the risk related to the accuracy is significantly reduced. Since the information is based on virtual sensors, their models can help avoid the big hidden cost when production strategy and process conditions are determined. The timely reporting of the part geometry also enables an early intervention to avoid further machining in case the part is going to be out of tolerance so that first-time production can be achieved. Proposed optical measurement and data driven methods add another layer of faster reporting. All of these lead to making parts within a short delivery time. These benefits are also very important for the machine tool builders since they are acting like enablers and equipping their machines with the new measuring system will enhance the competitiveness of the machines.

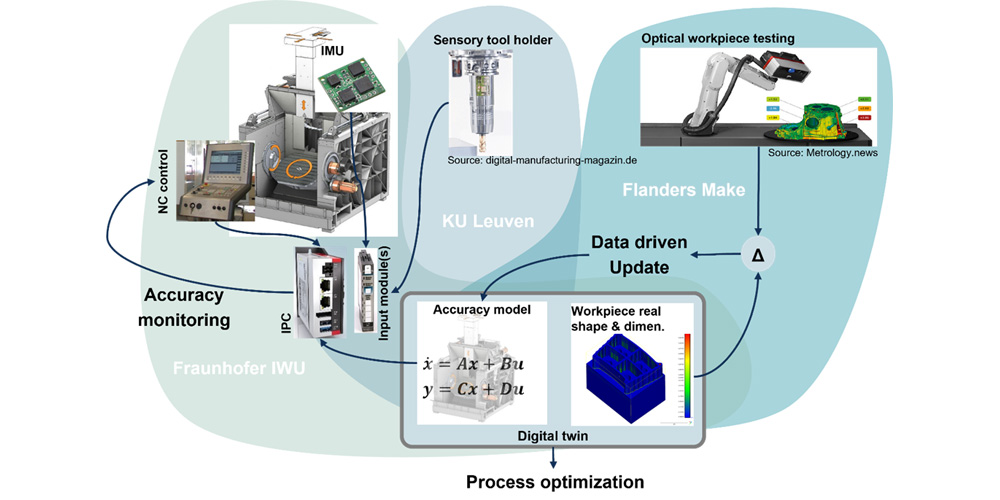

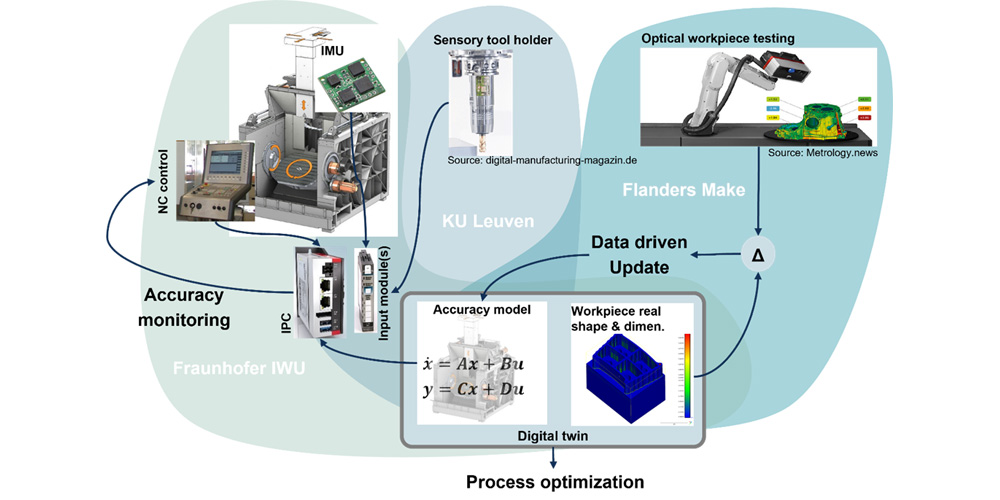

The overall goal of this project is to provide a new solution for monitoring the part accuracy during machining within reasonable costs and efforts. This solution is composed of four innovations:

- new measurement system based on inertial measurement units (Fraunhofer IWU)

- implementation of virtual sensors for accurate estimation of tool position (KU Leuven & Fraunhofer IWU)

- fast 3D scanning technology for work piece inspection close to machine (Flanders Make)

- deploying data-driven techniques for updating models in the virtual sensors (Flanders Make)

Project duration

October 2023 – September 2025

Founding

CORNET / DLR Projektträger

Project number

IGF 367 EBR/1

Project partners

- Flanders Make (BEL)

- VDW-Forschungsinstitut (DE)

- KU Leuven (BEL)

- Fraunhofer IWU

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology