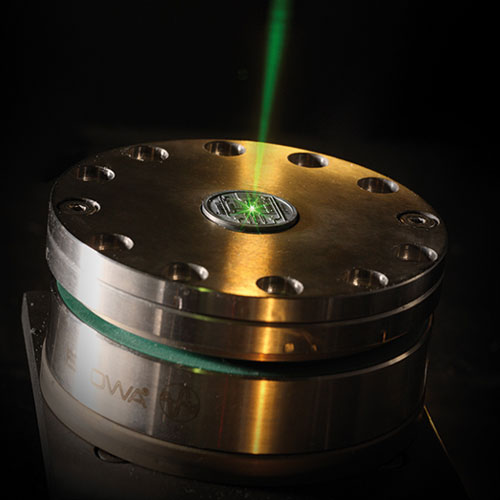

Laser structuring of shapes and surfaces

Microstructuring by laser enables precise machining of various microstructures. Materials, which are very difficult to structure using conventional manufacturing processes, can be machined by this method regardless of hardness, toughness and electrical conductivity. At the same time, structures can be generated with dimensions in the micrometer range.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology