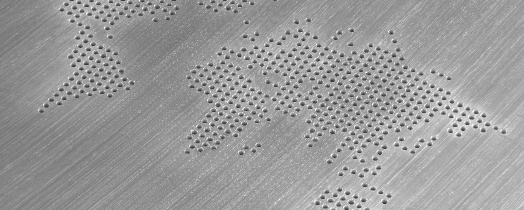

Micro electrical discharge machining – contact-free machining of hard materials

For machining smallest structures with highest precision, the width of the discharge gap has to be reduced. This reduction impedes particle expulsion, especially considering deep cavities such as micro bores, and can lead to a decrease in process speed and stability. Thus, at Fraunhofer IWU investigations are carried out for optimizing micro-EDM to allow for fast and reliable machining of high-precision micro geometries.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology