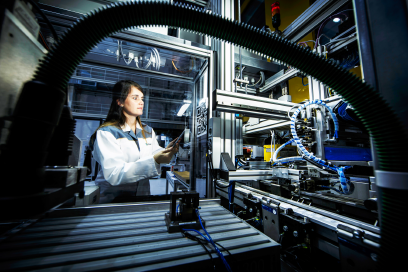

Planning, controlling and linking the factory of the future

We develop implementable solutions for factories to increase efficiency and added value. Our solutions result from a combination of information technology, business organization and mechanical engineering. In order to achieve the best benefits for our clients, we apply our competences and experience from local, national and international projects and offer support from the first idea up to realization. Sustainable solutions and services address the main topics of industrial production in Germany: Our research focuses on efficient use of energy as the main factor of production and on approaches “related to Industry 4.0” to acquire, process, link and use data in production. Moreover, we research active (re)integration of humans into production systems where humans play a central role.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology