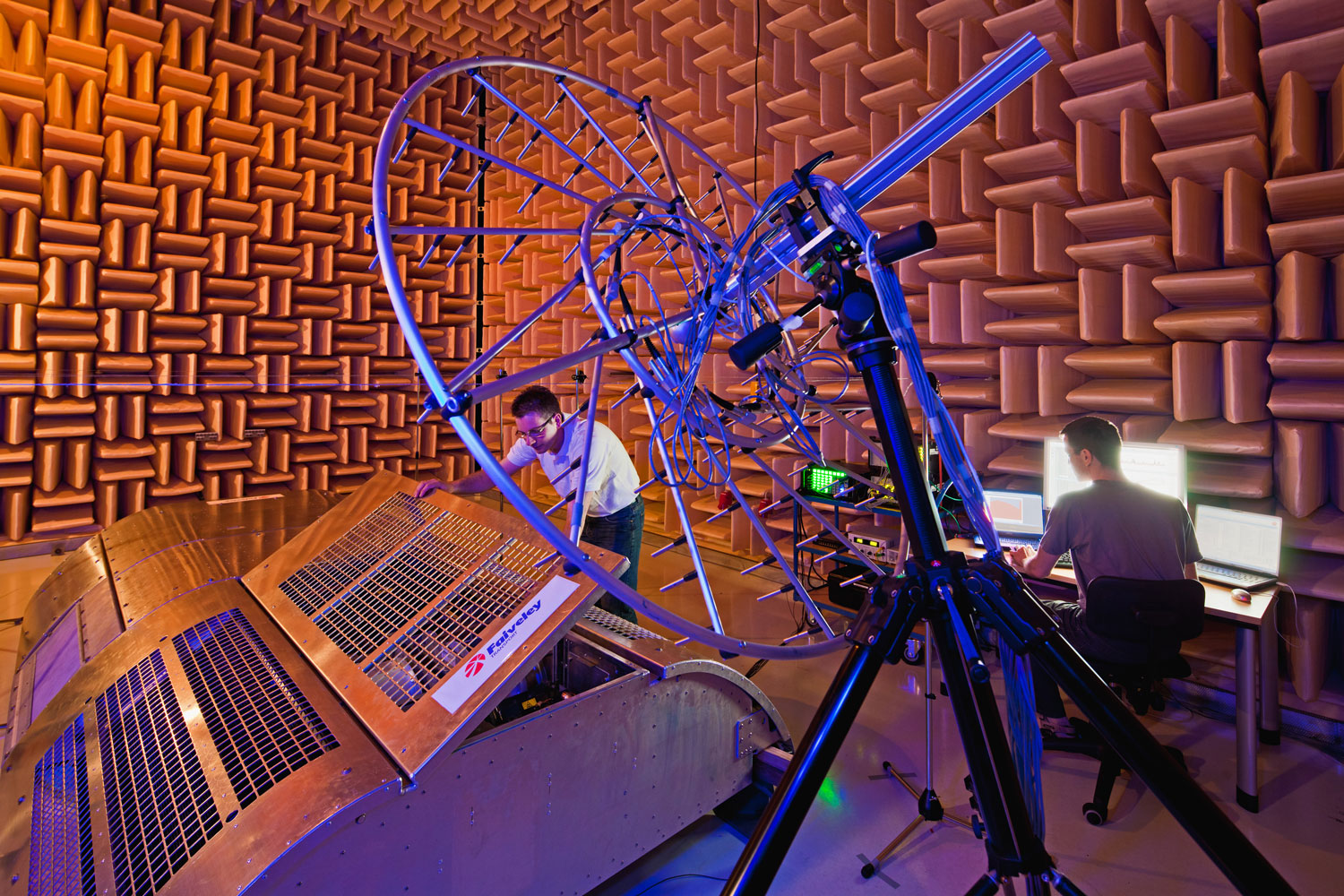

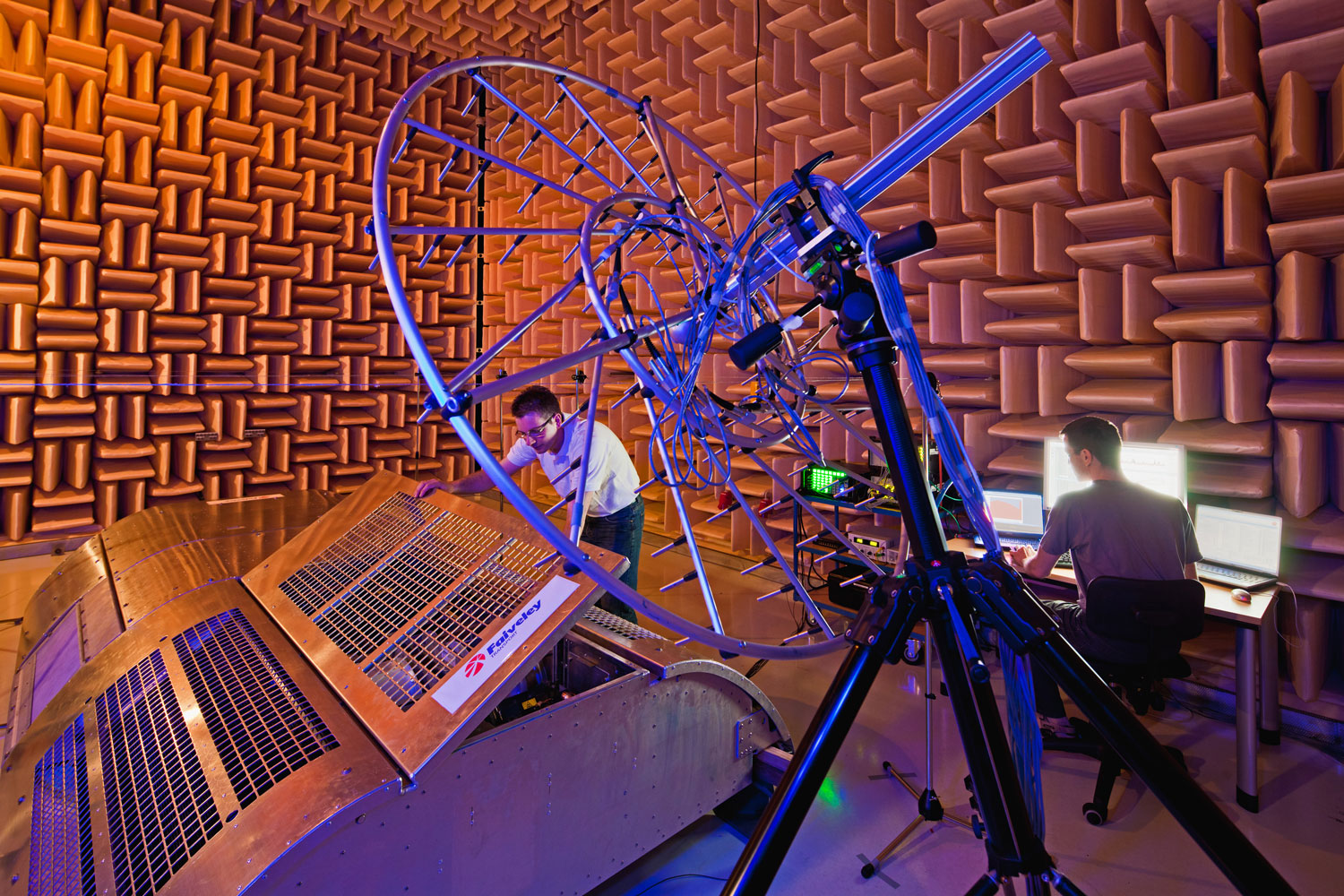

Quiet and light

The Fraunhofer IWU has extensive experience in the field of technical acoustics and uses various methods of analysis and acoustic measurement technology for solving diverse tasks.

The Fraunhofer IWU has extensive experience in the field of technical acoustics and uses various methods of analysis and acoustic measurement technology for solving diverse tasks.

Application examples for microphone array process