Innovative processes for lightweight construction and composite design

Innovative joining technologies are the basis for the implementation of sustainable component concepts. For example, we develop processes for joining high-strength steels with light metal alloys based on aluminum, magnesium and titanium as well as for joining material combinations of metals and fiber-reinforced plastics. The process optimization of joining tasks with regard to quality, reproducibility as well as energy and resource efficiency is another research focus. This includes the description of the entire production process for car body assemblies with the help of a consistent experimental and numerical analysis of the process chain (forming, joining and paint drying).

Trends

- Cost-effective joining of identical and dissimilar materials

- Lightweight and mixed construction: development of energy-efficient alternatives to resistance spot welding and other thermal joining processes

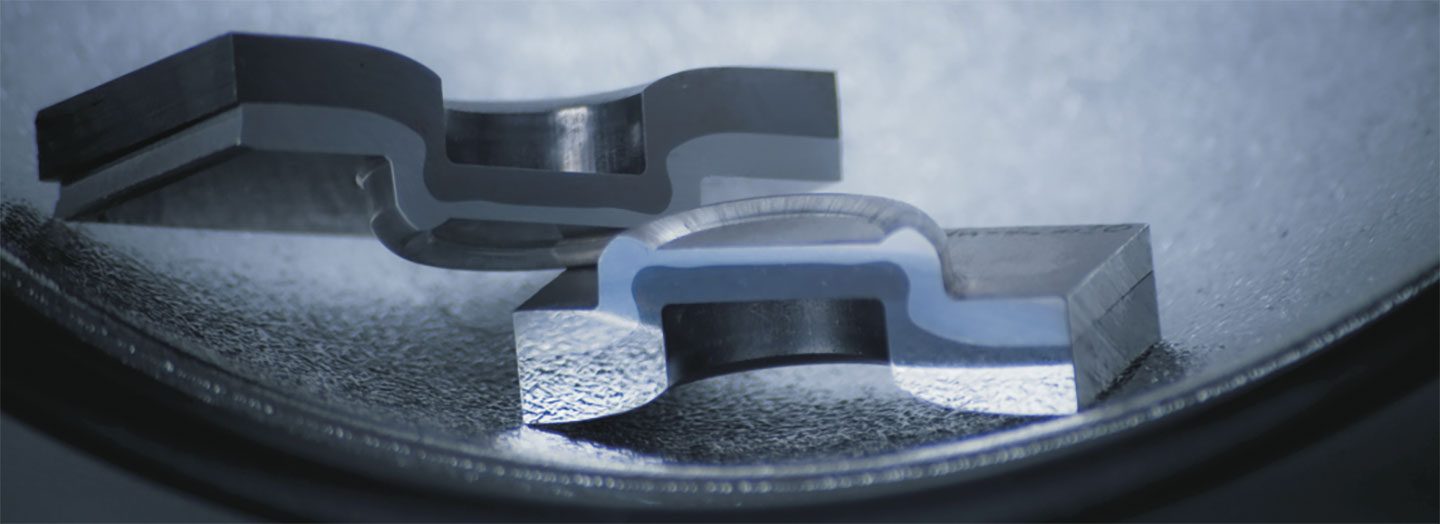

- Overcoming process limits and combining advantages through the use of hybrid joints (clinching, punch riveting, gluing, seam bonding)

- Targeted optimization of process influencing variables using simulation

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology