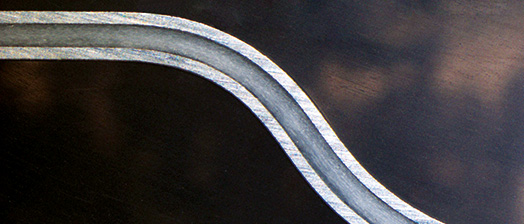

Forming of hybrid materials

Every construction material has specific properties which imply specific main fields of application. Often one single material cannot optimally meet the increasing component requirements regarding strength, stiffness, mass and damping behavior. Intelligent combination of various materials offers the potential of implementing the required component properties. Thus, metal materials are combined with other metal materials (e.g. tailored blanks of aluminum and steel), but metal materials are also combined with polymers or fiber-reinforced polymers. The processes of conventional sheet metal forming are predestined for economic, large-scale processing of these hybrid materials. Fraunhofer IWU develops customized process chains for forming of hybrid materials. This development comprises characterization of the hybrid materials and their individual components, process design (simulation, fundamental forming experiments), tool design, process control and process monitoring.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology