Small series production: cost-efficient and fast

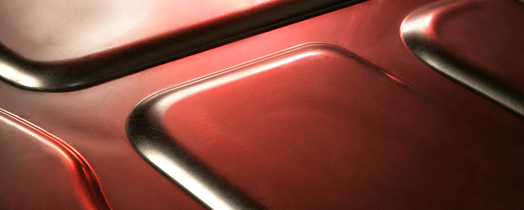

The technology of high-speed gas cutting uses the “airbag effect” for shaping sheet metal parts by applying high pressure. The basic tool includes the required safety and control technology. In addition, the bottom tool part contains the gas producers and the die is integrated into the upper tool part. Since this forming technology is based on active media, the die can be made of plastics or wood - materials suitable for rapid processing. Upon ignition, the pressure is built up within milliseconds and the component is pressed into the die, i.e. it is shaped. Small calibrated radii can be easily generated using this technology.

Due to the nature of the process, high-speed gas cutting is suitable for generating design studies, manufacturing prototypes or for industrial small series production. In particular, the process is characterized by reduced tool cost (only the die has to be manufactured specifically for the component) and by operating independently from the press. Usually the number of gas producers applied in this technology is considerably lower compared to the number built into airbags of mid-range cars.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology