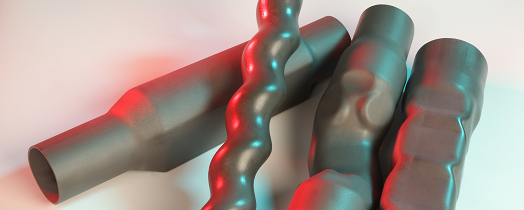

The hydroforming process (HF) uses internal pressure acting in all directions to force closed profiles against a die cavity, thus forming them in a controlled manner. The forming dies usually consist of an upper part and a bottom part with a corresponding parting plane. The active medium is introduced via axial sealing punches, which use axial pressure to reliably seal off the component from the environment. Depending on the component shape and sealing concept, additional material can also be forced into the forming zone in order to extend the range of component shapes that can be geometrically realized. This process makes it possible to produce unique component geometries that are impossible or extremely complex to produce using other production processes.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology