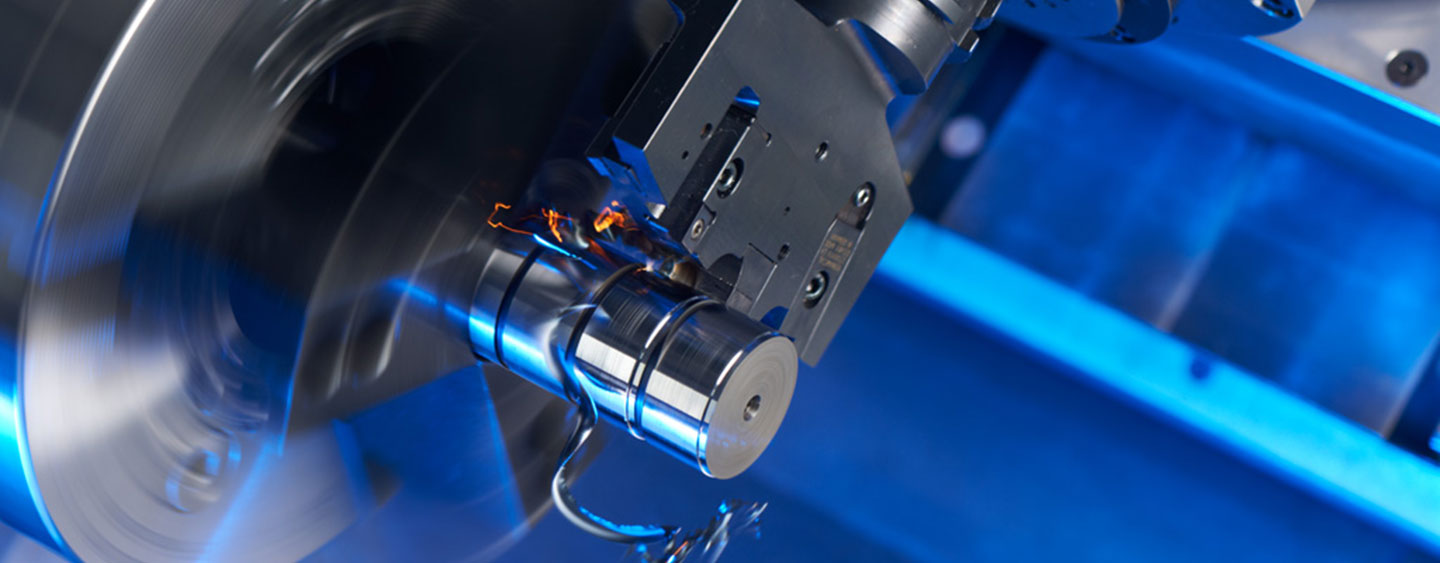

Processes, tools and high-performance components for cutting and removal

Current challenges in production technology comprise designing processes to be more resource-efficient, more energy-efficient and more reliable. Furthermore, the manufactured components shall possess additional effects such as less friction, lower wear or consumption. As a result, our field of action is highly complex, ranging from energetic evaluations of manufacturing processes to designing resource-efficient process chains, extending process limits and developing process combinations or substituting operations, developing specific tools and machine technology.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology