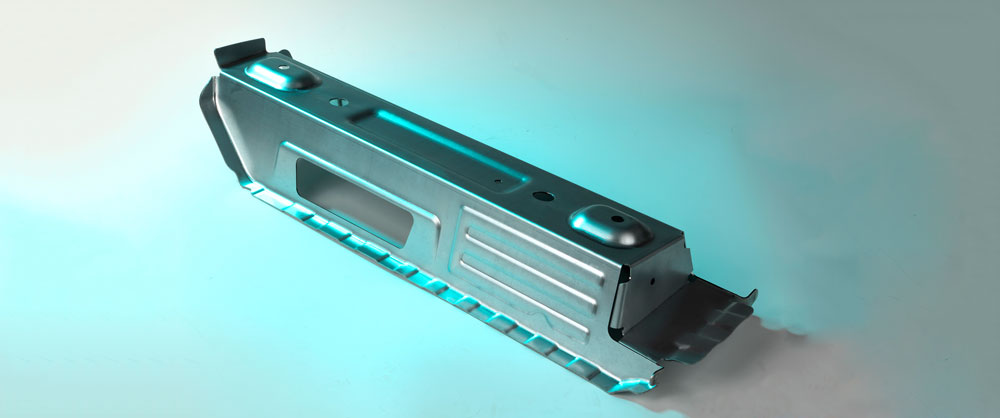

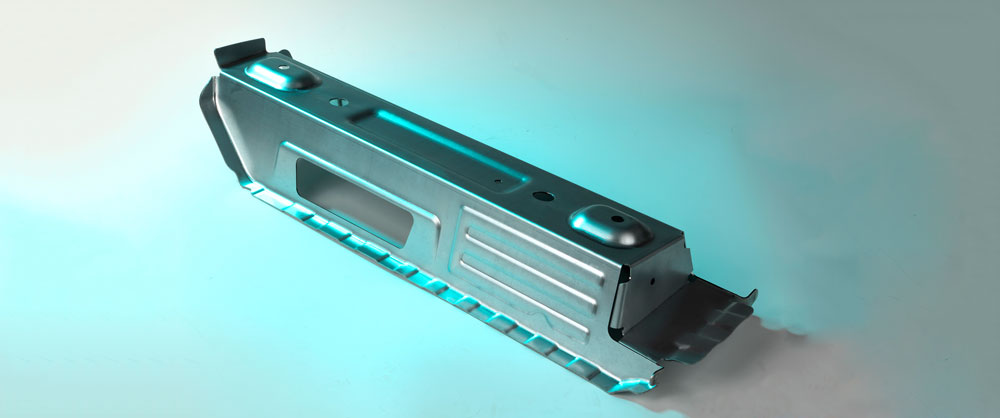

StaBiFü® - economical alternative to deep drawing of sheet metal structural components

Challenge

As vehicle manufacturers (passenger cars, commercial vehicles) expand their model ranges while overall vehicle production in Europe stagnates, the quantities of sheet metal components per derivative decrease. The use of large and gigacast parts further reduces the demand for sheet metal parts, pushing conventional manufacturing processes (deep drawing) in press shops to their economic limits, as the high costs of component-specific forming tools can only be amortized over large quantities.

Objective The goal is to develop alternative process chains characterized by tool-reduced or tool-free manufacturing. In addition to improving pure economic efficiency in terms of cost per component for small and medium quantities, further advantages in agility and sustainability are achieved. This allows complete process chains from coil to ready-to-install, paintable components to be implemented, adapted to various conditions, and optimized according to different target specifications.

Social Relevance

Tomorrow's value creation requires new approaches that enable investment-lean, agile, and highly flexible manufacturing of sheet metal structural components. Additionally, the technological approach makes significant contributions to improving sustainability. Minimizing direct material usage (approx. -20%) conserves material resources, as does the significant reduction in operating material requirements. This can lower the CO2 footprint to 10% or 1 per mill compared to conventional manufacturing methods.

Approach / Solution

Unlike the manufacturing of sheet metal structural components through linear, rigidly linked processes, the StaBiFü® approach develops a highly flexible, adaptive manufacturing method similar to matrix production. By adjusting the degree of automation in the linkage, this manufacturing method offers high flexibility and is particularly suitable for short response times and investment-sensitive applications. Most current component designs can be manufactured with minor adjustments using the new approach. A geometric analysis of the components provides insights into which areas should be redesigned. These geometric features can be assigned to multiple manufacturing technologies, forming a variety of technological graphs that, when linked with available resources, serve as the starting point for numerous optimizations. These can be used for planning purposes but also offer the option to adapt process chains based on ongoing production and capacity utilization.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology