Fraunhofer IWU at Hannover Messe 2022 in Hall 5, Booth H06

Strong innovations: "Reference-factory.H2", intelligent machine components in adaptive process chains, human-robot interaction and soft robotics demonstrate solutions for industrial green hydrogen, the factory of the future, household, and nursing

May 30 to June 2, Hannover Messe 2022, at the joint Fraunhofer Booth: Advancing the industrial production of electrolyzeres and fuel cells. Considering manufacturing as a whole brings production to an entirely new level. Safe and high-performance soft robotics for near-human tasks. Intuitive programming makes robotics fit for a wide range of applications in industry and trade.

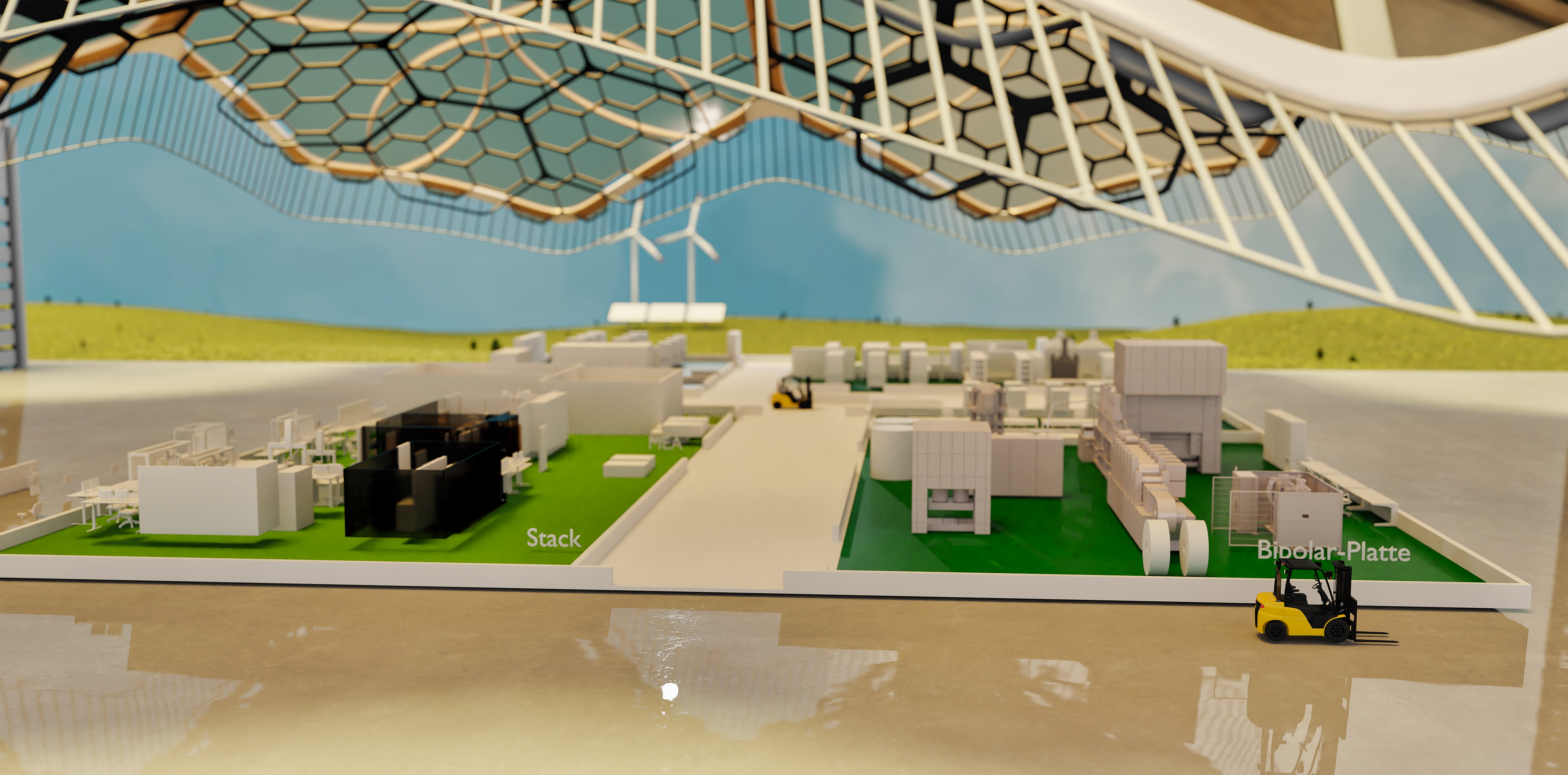

Reference-factory.H2: advancing the industrial production of electrolyzers and fuel cells

Anyone who considers acquiring a photovoltaic system for their domestic roof may consider a significantly lower budget than ten or fifteen years ago, in spite of current price fluctuations. Highly efficient industrial large series production realizes the lower prices. An individual item produced manually would hardly meet today’s requirements regarding durability, efficiency, or resistance against hail, and it would be unaffordable. Be it highly complex products such as cars and smartphones or convenience goods: it is only their production at a high number of pieces using appropriate production processes that makes these products affordable. This is also true for hydrogen. In order to render hydrogen into a backbone of climate-neutral energy supply, it is essential to produce it at market-based prices, in sufficient quantities, in a climate-neutral way, and to use it with a high CO2 reduction factor. For this purpose, essential hydrogen systems have to be transferred into industrial series production, which particularly applies to electrolyzers – they separate water into hydrogen and oxygen by using power, e.g. from wind or solar energy – and fuel cells that convert the generated hydrogen into electrical energy. The Reference-factory.H2 focuses on technologies that shall enable industrial production with significant advances in processes, digitization and cost. Large series production shall become profitable through research on cost-efficient materials, component quality, longevity, improved production technologies, scalability of the production processes, their automation, the linking of production lines, the establishment of efficient supply chains and on factory planning. Dr. Ulrike Beyer, Head of the Hydrogen Task Force at Fraunhofer Institute for Machine Tools and Forming Technology IWU and coordinator of the project, says: ”Production has to make a considerable contribution to a breakthrough of hydrogen. This is exactly what we deal with at the Reference-factory.H2.” A total of 30 million euros of federal funds are available to meet this challenge.

From May 30 to June 2, Reference-factory.H2 will be presented for the first time at Hannover Messe 2022 at the joint Fraunhofer Booth in Hall 5, Booth A06.

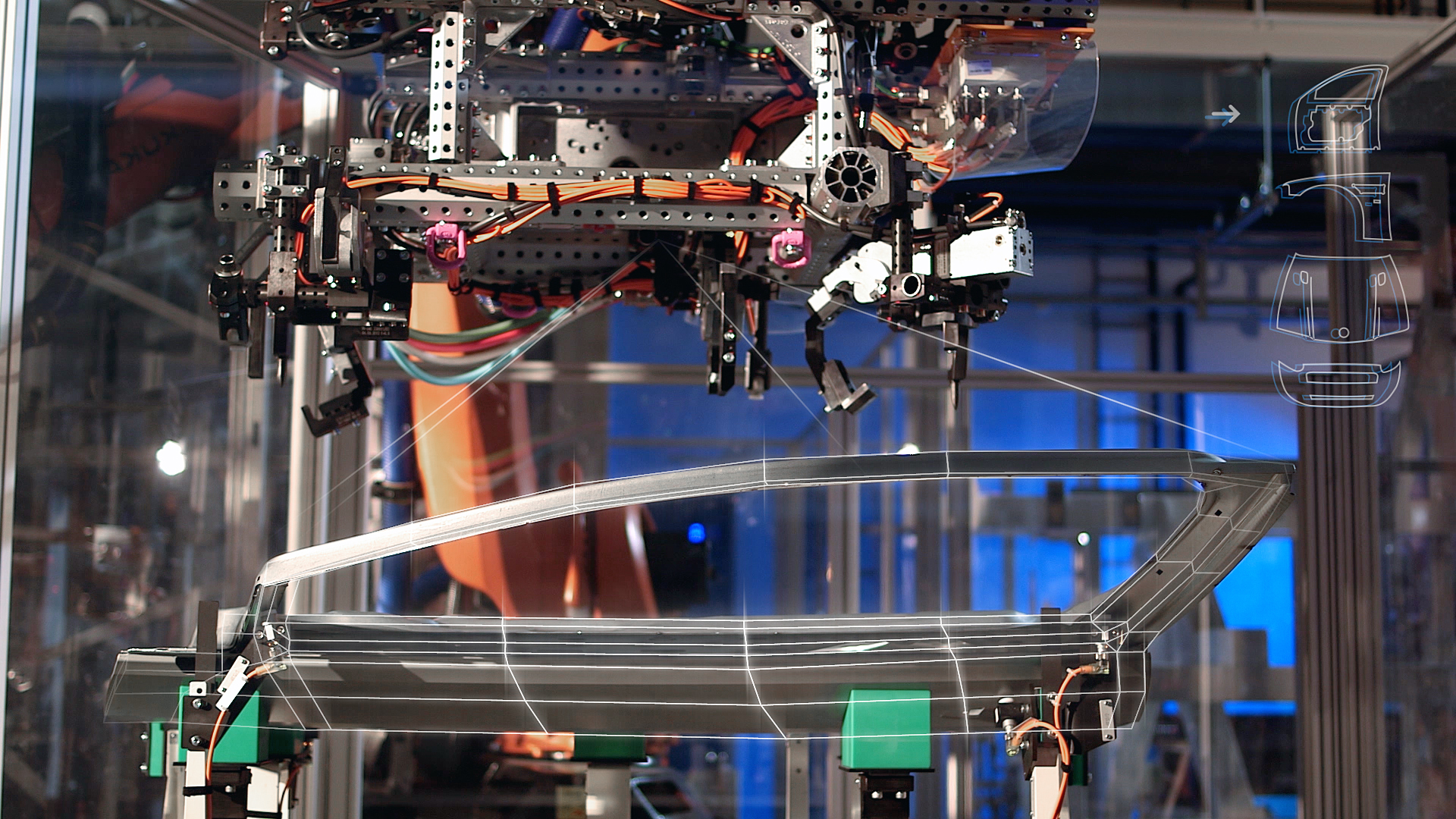

Adaptive process chains: considering manufacturing as a whole brings production to an entirely new level

Modern efficient factories use humans as examples. As a learning system, the human capability to adapt flexibly to changing environmental conditions is a good example for every production system. In our day-to-day life, we are always dealing with variance, we can adapt to different situations in a flexible way. All humans have to eat and drink, although without adhering to a fixed time schedule. If there was no time for a big lunch, dinner will be larger. If our checkout line is long, we can also pay our shopping at a different checkout. Procedures and routines correspond to processes in factories – and they can still learn a lot from humans regarding their adaptability.

Modern production processes as a result of continuous optimization

In industrial production, efficiency, stability and production quality comprise important factors. Employees in production can further develop simple processes without any trouble, and they can detect and correct errors. If the manufacturing of complex products in sophisticated supply chains is to be improved, sensors will help detect potentials for optimization at the considered manufacturing stage while artificial intelligence will help structure them and actuators will enable their realization. How will this improvement match the previous or subsequent production stage? It is essential to understand all interactions in the entire process chain, including logistics and upstream and downstream processes. What does improving mean in this context? That depends on the goal: It may be reasonable to scrutinize specific tolerances of individual components without questioning the required quality of a product as a whole. Thus, the deviation could be accepted in an individual process, if it can be compensated later without problem. If the same overall goal can be achieved with less effort, the effort can be reduced accordingly. Less standstill, less need for intervention and lower cost would be the desirable effect. Dr. Wolfgang Zorn, Head of the Business Unit Adaptive Process Chains at Fraunhofer IWU, explains the basic idea of such adaptive process chains: “Components do not always have to be perfect, but they have to be perfectly compatible.”

Fraunhofer IWU recognizes a huge potential for future production processes in the adaptivity of process chains. In the project "AdaProQ", Fraunhofer IWU - together with twelve consortium partners under the direction of Grammer AG - develops generic methods for mastering the production quality in complex process chains. The focus lies on automotive manufacturing. AdaProQ covers a project volume of 19.1 million euros and is funded by the Federal Ministry for Economic Affairs and Climate Action. Fraunhofer IWU contributes a broad spectrum of competencies that is coordinated by Dr. Wolfgang Zorn as the project manager.

Fraunhofer IWU pursues a long-term strategy for establishing methodical competence in its business unit. The complexity of this task is considerably increased when dealing with a supply chain since complex logistical process have to be considered. Artificial intelligence, sensors, actuators and data management form the backbone of adaptive process chains. In Hall 5, Booth A06 at the Hannover Messe Fraunhofer IWU shows three selected projects and their first approaches toward adaptive process chains.

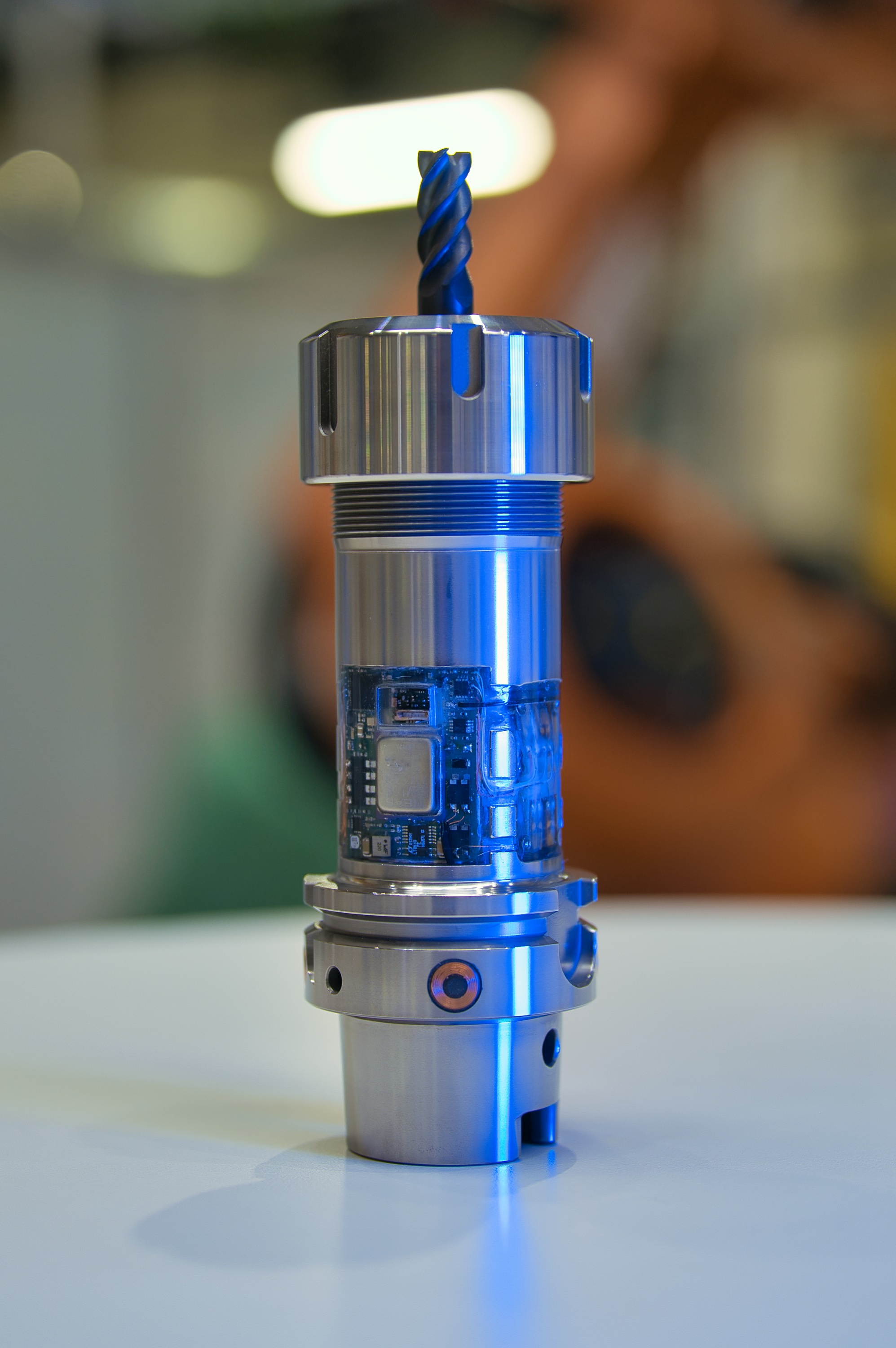

Intelligent tool holder in cutting: "smartTOOL"

For quality and productivity in cutting, it is more important than ever to be able to monitor processes as close as possible to the point of action. The intelligent tool holder smartTOOL is a very economical solution which thanks to its independent energy supply is also suitable for retrofitting. It is able to record valuable process data close to the cutting process. Process forces, vibrations and temperatures can be recorded, evaluated with the appropriate algorithms and converted into process parameters. These parameters in turn serve as a basis for monitoring or even adaptive process control - smartTOOL thus gathers the data needed to get also older machines fit for the production of the future.

Adaptive profile rail guide for higher economic efficiency of machine tools

Setting the profile rail guide in machine tools means determining a pressure level, i.e. a preload class, in advance. In day-to-day operations too much preload is usually applied, which means that the machines wear out unnecessarily early. Fraunhofer IWU has developed a solution to this problem: the preload class can be set in a highly dynamic manner during operation using piezo actuators. Thus, the contact pressure can be controlled as needed. Existing machine tools can be retrofitted with this technology, resulting in more economic operation.

Miniaturized actuators as key elements of production plants

Actuators are key elements in almost any production plant and machine. Actuators based on thermal shape memory alloys (SMA) can be used where the space is too small for conventional actuators (e.g. piezo, pneumatic or hydraulic actuators). In the project HochPerForm developed by Fraunhofer IWU together with Fraunhofer IPM and IFAM, the cooling process is to be accelerated by a factor of 100 using switchable heat pipes. Thus, the working frequencies can be increased to over 1 Hz. For further miniaturization, additive manufacturing processes are used, which are intended to enable optimal use of the available installation space.

Safe and high-performance soft robotics for near-human tasks

When mowing the lawn, we have already become accustomed to their support – in other near-human tasks regarding household or nursing, there are hardly any approaches for robots. Using novel switchable stiffness in robots, Fraunhofer IWU unites the required force with the appropriate safety. At the Hannover Messe, the researchers present a robot arm that can support humans in their direct environment.

Interaction³: multimodal ways of human-robot interaction

Programming robots has never been this easy: using the multimodal interaction system developed by Fraunhofer IWU, production workers will be able to use their fingers to program the motion processes of robots. The programming by finger tracking and voice command can even take place remotely. Using this technology, robotics can be used efficiently and much more flexibly, even for batch size 1 (e.g. painting and polishing in crafts). Dr. Mohamad Bdiwi and his team are looking forward to visitors who want to train a robot intuitively at the joint Fraunhofer booth.

- Press kit for the Hannover Messe 2022 (fraunhofer.de)

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology