Functionally integrated lightweight design in electric mobility

EV Battery Enclosures with Lower Carbon Emissions

More charging power, higher range, lower environmental impact: In the COOLBat joint research project, researchers from the Fraunhofer Institute for Machine Tools and Forming Technology IWU have teamed up with partners to develop next-generation battery enclosures for electric vehicles. The objective is to make the enclosures, a central component in any electric vehicle, lighter and cut the carbon dioxide emitted to manufacture them by 15 percent. The project partners aim to achieve this by combining individual systems, packing more functions into a smaller installation space, and using new heat-conductive materials and bio-based flame retardant coatings.

Achieving climate-friendly production of enclosures for battery systems in electric vehicles and thereby shrinking the vehicles’ carbon footprint is the goal for the industry and research sector partners working on the COOLBat project, which focuses on carbon-cutting lightweight construction solutions demonstrated by next-generation battery housings. This is because current battery enclosures, with their structures for load distribution and temperature regulation, frames, lids, and base plates, still offer potential for cutting carbon emissions. In the project, 15 partners are conducting interdisciplinary research on innovative lightweight construction principles to reduce mass and on lightweight construction materials and production methods intended to make production of battery system enclosures ecofriendlier and improve their properties in use. The partners are pursuing a broad-based approach that centers aspects such as circularity and repairability, resource and energy efficiency, safety, and fire protection at the design and material levels. Fraunhofer IWU in Chemnitz is coordinating the project, which is receiving funding from the German Federal Ministry for Economic Affairs and Climate Action (BMWK) as part of the technology transfer program for lightweight construction (TTP-LB) and is supervised by the Project Management Jülich (PTJ).

The principle is simple: The lighter the enclosures, the greater the range of electric cars, as power consumption decreases. “The energy density of present-day battery systems has plenty of room for improvement, and battery enclosures are a key aspect there. Integrating new lightweight construction methods and more functions in a smaller installation space with fewer interfaces makes it possible to reduce weight while also cutting carbon emissions,” says Rico Schmerler, a project manager and scientist in the Battery Systems department at Fraunhofer IWU. “Reducing mass lets us increase energy density, and thus range, even as the number of battery cells stays the same. By making the enclosure lid out of a fiber composite material, we were able to reduce the mass by more than 60 percent compared to the reference out of steel.”

Cooling and load-bearing capacity in one component

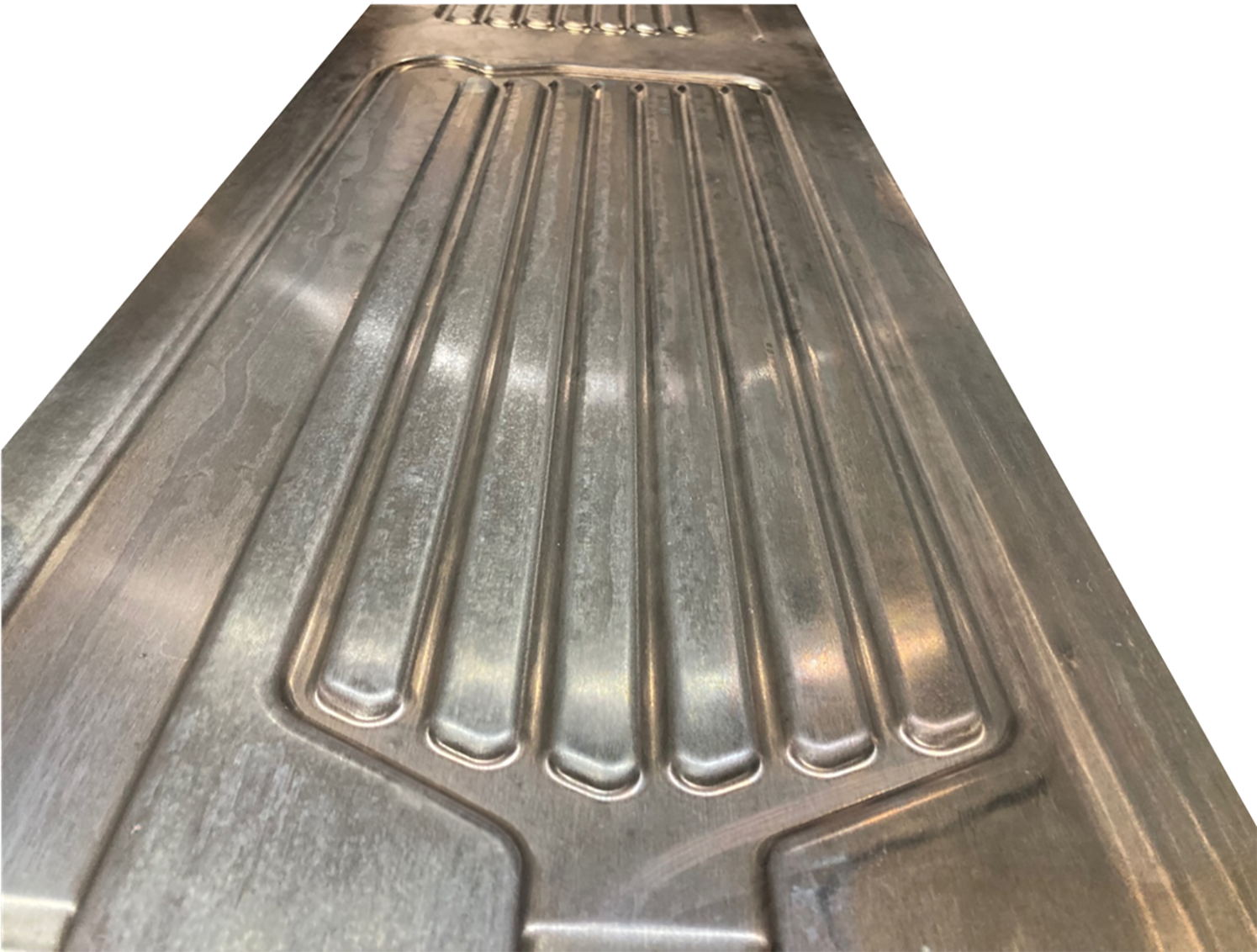

Another avenue the researchers have identified for potentially reducing weight is combining individual systems in the enclosure that previously performed thermal and mechanical functions separately. For example, cooling channels cast at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM are incorporated directly into load-bearing structures such as cross beams.

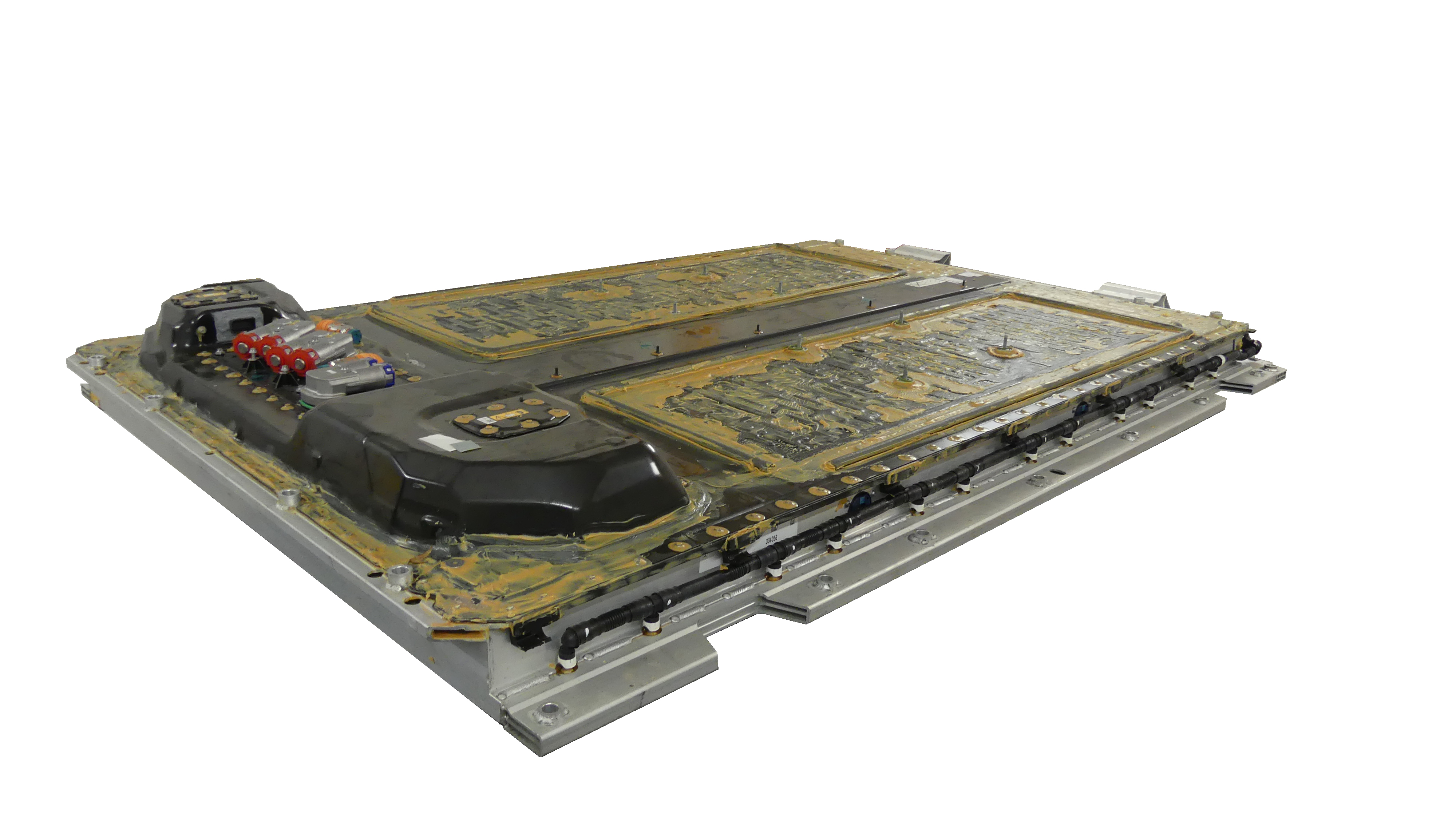

In addition, the cooling unit function is combined with that of underride protection in a single component, the base plate. Aluminum foam inside the base plate absorbs the impact energy from stone impacts and accidents. Combined with a phase-change material (PCM), a kind of wax that can be used to store and later release a wealth of thermal and cooling energy, the aluminum foam also lowers the amount of energy needed to cool the electric battery. The base plate was developed by Fraunhofer IWU and FES/AES and produced at Fraunhofer IWU, including the foam.

This configuration protects the battery cells from mechanical loads and overheating at once. A fluid flows through the channels, cooling the cells not only from below but also from the sides. This reduces the electricity needed to cool the cells and eliminates the need for cooling elements elsewhere in the vehicle. “We’re focusing on functionally integrated structures. Tasks that used to be handled by different modules inside the battery are being integrated into a single component — the base assembly, in this case — to shrink the installation space and streamline interfaces,” Schmerler explains. “These base plates will provide protection from overheating and avert damage to the battery core in case of an accident.” The researchers are using the Mercedes EQS battery as a reference and technological demonstrator.

New thermal pads replace pastes

The quality of the heat dissipation from batteries toward the exterior shell has a significant impact on an electric vehicle’s performance and lifespan. Conductive pastes are typically used to connect the battery module for thermal purposes. One of the aims of this project is to replace these heavy, non-sustainable pastes with ecofriendly heat-conductive materials. To do this, the Fraunhofer Institute for Surface Engineering and Thin Films IST is using a plasma process to metallize open-pored reusable foams that are then placed in the spaces between the battery and enclosure in pad form.

Bio-based flame retardant coatings improve fire protection

A new flame retardant coating developed by the Fraunhofer Institute for Wood Research, Wilhelm-Klauditz-Institut, WKI is helping to improve safety. Applied to the underside of the enclosure lid, it prevents fire from spreading from the battery cells beneath. The coating also contains lignin, a non-flammable bio-based material that takes the place of petroleum-based materials.

Design for reuse

The previous enclosure lid, which was made of steel, has been replaced with a new fiber composite lid structure made of carbon and resin (known as a towpreg), which has not only significantly reduced the component’s mass but also made it possible to reuse the lid. The entire system comprising the lid, frame, and base plate has been designed to be disassembled and removed nondestructively down to the component level. “We are pursuing the concept of a circular economy and material reduction through lightweight construction and reusable materials, which in turn results in a smaller carbon footprint and lower repair costs,” Schmerler says.

Sights set on industry transfer

Future plans call for the project’s various results to be extended to other applications and industries where large batteries are used, such as in trains, aircraft, and boats. The cooling systems could also be used for transporting food and medications, and the fire protection solutions could be used in buildings. Further partners in the COOLBat project are Auto-Entwicklungsring Sachsen FES/AES, INVENT GmbH, Compositence, iPoint-systems, TIGRES, LXP Group, Basdorf, Lampe & Partner, MID Solutions GmbH, Synthopol, TRIMET Aluminium SE, Mercedes-Benz AG, the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM, the Fraunhofer Institute for Surface Engineering and Thin Films IST, and the Fraunhofer Institute for Wood Research, Wilhelm-Klauditz-Institut, WKI.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology