Steel-Aluminum-Sandwich

Steel-Aluminum-Sandwich

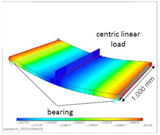

Calculation results of the centric loaded Steel- Aluminum-Sandwich with boundary conditions

Information

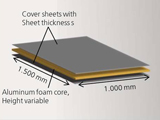

- Steel plate: S235 (St 37)

- Foam: aluminum basis

- Length x width: 1.500 mm x 1.000 mm

- Composite: metallic bond or glued joint

- Fields of application

Applications

- Automotive industry (car body knots, longitudinal beams)

- Engineering (fast moving devices, devices with high damping requirements)

- Building industry (light and bearing floor elements/ columns)

- Shipbuilding industry (hatches, doors)

- Aircraft industry (floor slabs)

Characteristics

Plate dimensions uncut:

1.500 x 1.000 x Sandwich thickness [mm³]

| Sandwichthickness [mm] |

15 | 20 | 25 | 25 | 30 | 30 |

| Steel sheet thickness s [mm] |

2 | 2 | 2 | 3 | 2 | 3 |

| Overallmass [kg] | 58,7 | 63,9 | 69,2 | 90,6 | 74,4 | 95,9 |

| Max. deflection due to own weight [mm] |

0,523 | 0,299 | 0,198 | 0,195 | 0,144 | 0,137 |

| Max. reference stress due to own weight [N/mm²] |

3,99 | 3,02 | 2,48 | 2,42 | 2,14 | 2,03 |

| Max. deflection [mm/1000N] | 1,447 | 0,759 | 0,466 | 0,349 | 0,314 | 0,233 |

| Max. reference stress [(N/mm²)/1.000 N] | 14,7 | 10,2 | 8,0 | 6,4 | 6,7 | 5,4 |

| Lightweight construction factor LCF=1/(mass*deflection) *1000 |

11,8 | 20,6 | 31,1 | 31,6 | 42,8 | 44,8 |

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology