Finished parts in record time

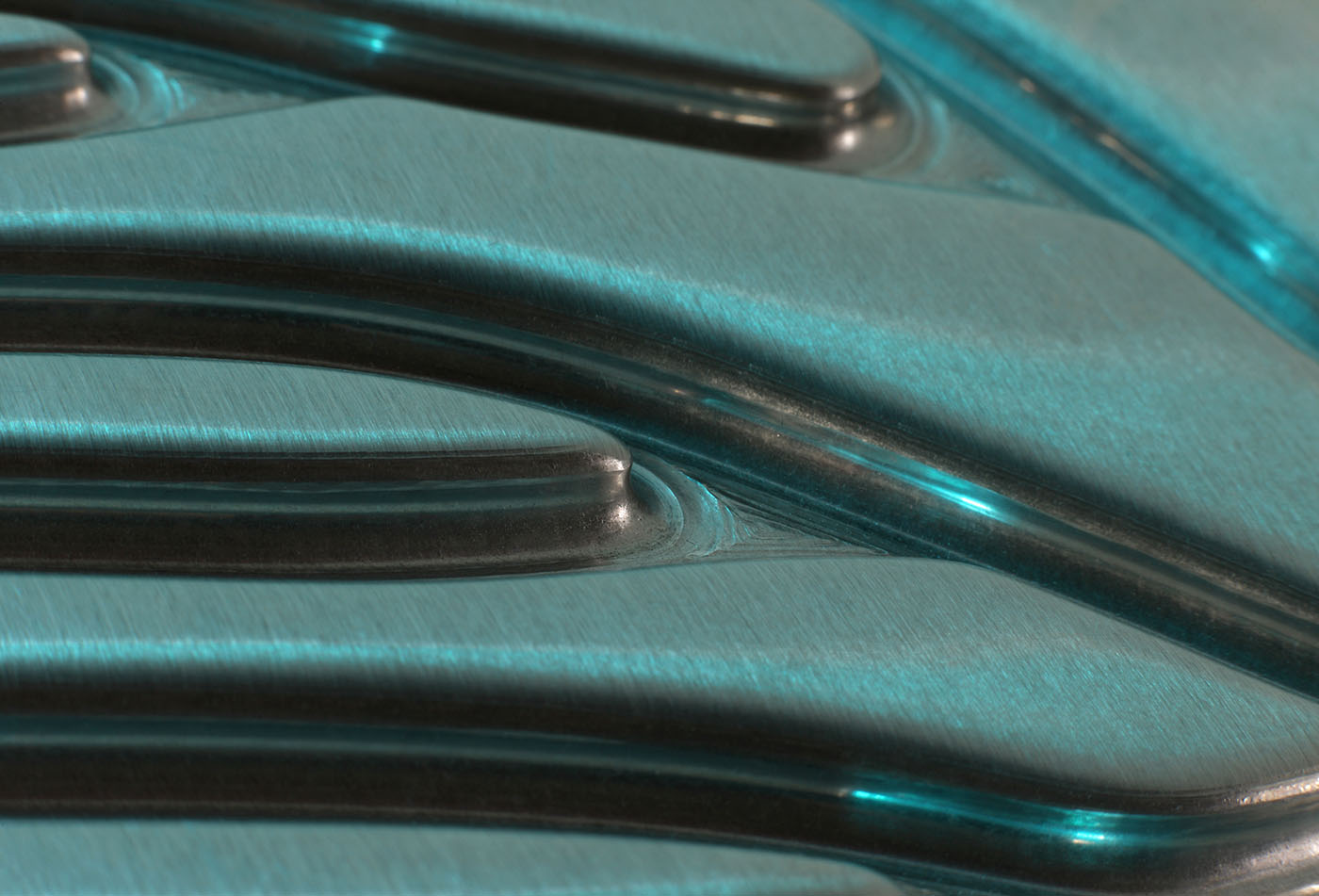

Incremental sheet forming is a forming process used to produce complex components in small quantities. Compared to conventional drawing processes, it eliminates the need for elaborate tools. This reduces tooling costs and the time required to produce the first finished part. These advantages make incremental sheet forming ideal for quantities ranging from 1 to 1,000 parts.

At Fraunhofer IWU, various options for incremental sheet metal production are available. The process variants used can achieve significantly higher degrees of forming than conventional methods. As the term "incremental" suggests, the final shape is achieved through multiple, successive movements. Specifically, these movements are performed by a forming mandrel, which is moved along a CNC path or multiple successive CNC paths. The programmed path directly influences the geometry of the produced component.

Trends:

- Minimal tooling costs

- Component production in the shortest time

- Broad application spectrum (visible and structural components)

- Further processing/individualization of existing components possible

- Surface qualities tailored to your specifications

- Cost-efficiency starting from a quantity of 1

- Component dimensions up to: 4,000 x 2,000 mm (cold) 2,000 x 1,000 mm (max. 250 °C)

- Sheet thicknesses up to 5 mm (Al) can be processed

- Applicable to a wide range of sheet materials

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology