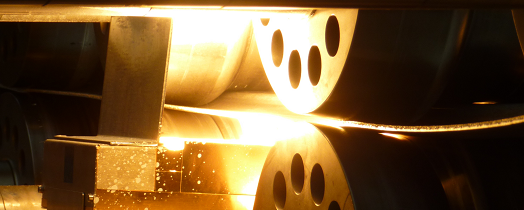

Shape rolling of profiles

Shape rolling is a forming process of bending using rotating tool movement (DIN 8586). Fraunhofer IWU has a shape rolling system with 9 profiling frames that can be arranged flexibly and whose output shafts are driven individually by servo motors. Shaping can be conducted with metal sheets up to a width of 500 mm. Our focus lies on integrating secondary operations (e.g. cutting operations, tempering) and on investigating sheet metal materials relevant for lightweight construction such as press hardening steels and magnesium wrought alloys. We create process designs using FEM, including the software COPRA, Abaqus and LS-Dyna.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology