Functional integration in sandwich sheets

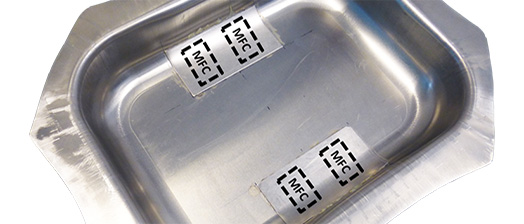

The objective is to develop a technology suitable for mass production for reliable, reproducible manufacturing of formed sandwich components which include functional integration of sensors and actuators. The central approach deals with the integration of planar piezo elements into aluminum sandwich sheets by adhesive bonding, followed by forming to obtain structural components. Significant reduction of the tensile and compressive loads acting on the piezo element is achieved by a floating fixation of the piezo element during forming, i.e. a piezo element is embedded into an adhesive between a sheet metal layer and a top layer; forming occurs in the viscous state of the adhesive. The final component requires a rigid connection between the piezo element and the sheet metal, which takes place due to curing of the adhesive after the forming operation.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology