Magnesium sheets

Magnesium is characterized by low density (1.78 g/cm³), great strength and stiffness and almost unlimited availability. For these reasons magnesium, and particularly wrought magnesium alloys, become more and more significant as lightweight materials.

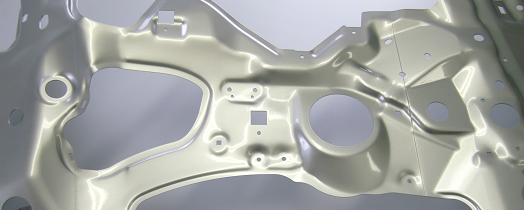

Thus Fraunhofer IWU develops processing technologies enabling the use of magnesium in various fields of application. Using two technological automotive demonstration units as an example, development and implementation was performed for the processes of deep drawing, stretch drawing, tube bending, shape rolling, hydroforming, extrusion and laser welding. Furthermore, characteristic material values were determined for tempering, which clearly facilitated FE models.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology