Precision cutting: an alternative to fine blanking

The innovative process of precision cutting is characterized by single-stroke shearing of sheet metals using a plane blank holder and overarm as well as rounded cutting edges and a small die clearance.

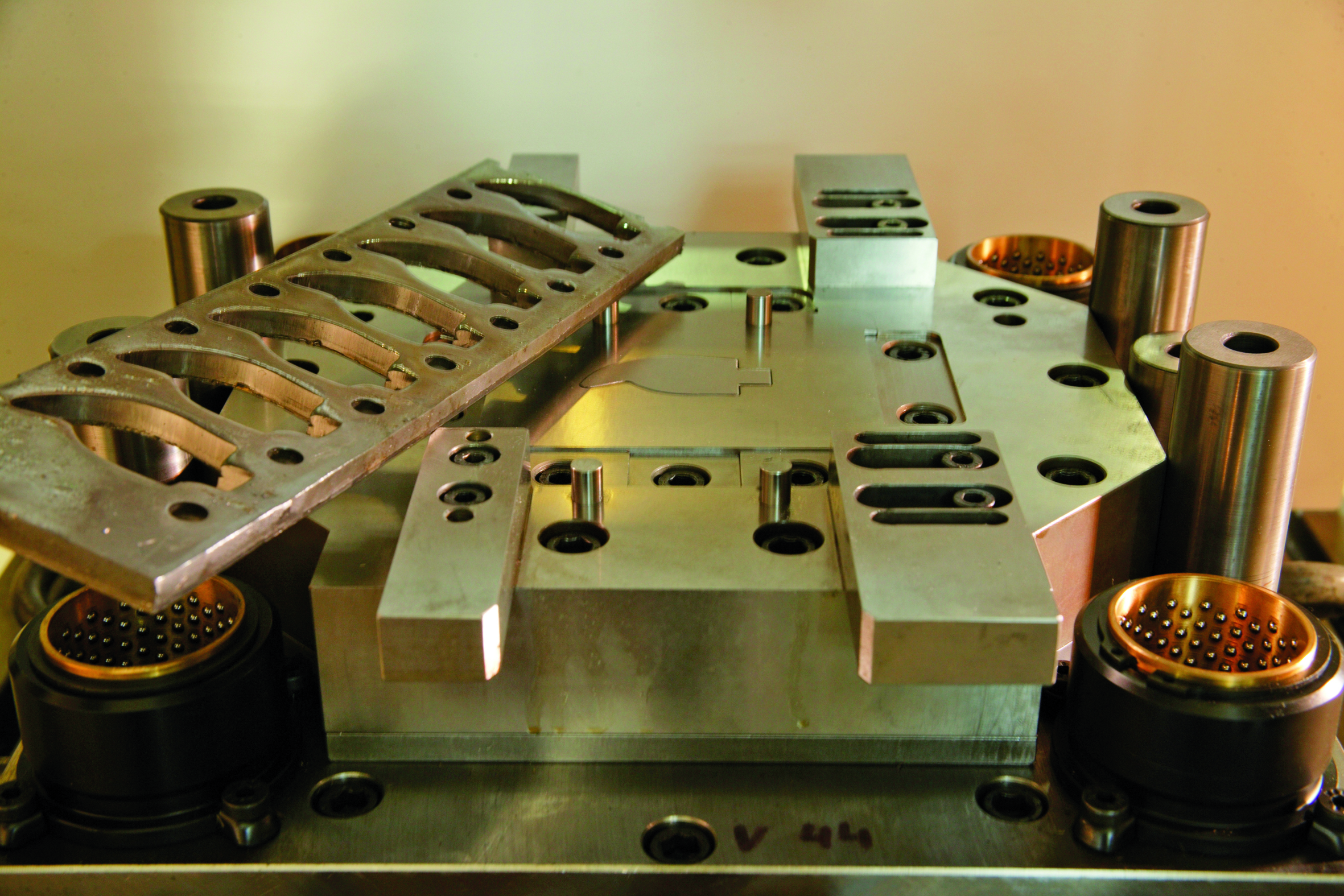

Precision cutting is regarded as a process between shearing and fine blanking. Tolerances between IT 9 and IT 11 can be realized utilizing relatively simple equipment. In terms of cost and achievable dimensional tolerances, precision cutting is the first process closing the gap between shearing and fine blanking. Applying this process makes it possible to obtain large proportions of smooth cut in progressive compound dies. In contrast to fine blanking, precision cutting does not require any tools with limited installation space or specific presses.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology