Motivation

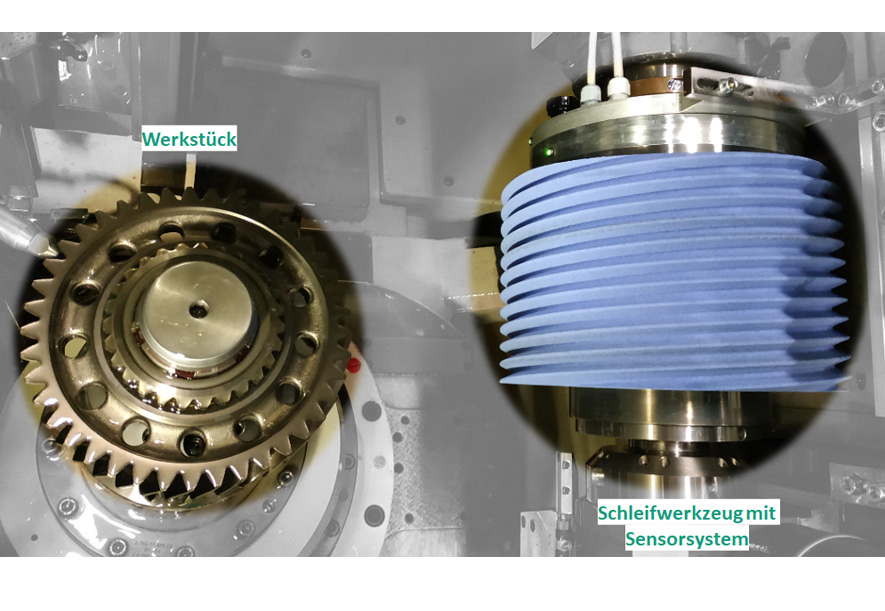

Gear grinding is a key process for hard finishing of gears and usually takes place at the end of the value chain of a component. The quality of the machined part is critically dependent on the condition of the grinding worm. A grinding worm can lead to grinding burns, increased roughness, or geometric deviations. Currently, a reliable assessment of the grinding worm condition during the process is hardly possible. As a result, high safety factors are considered in process design, leaving valuable potential for productivity improvement untapped. To exploit this potential, a process monitoring system is needed that captures and evaluates the condition of the grinding wheel in real-time.

Solution

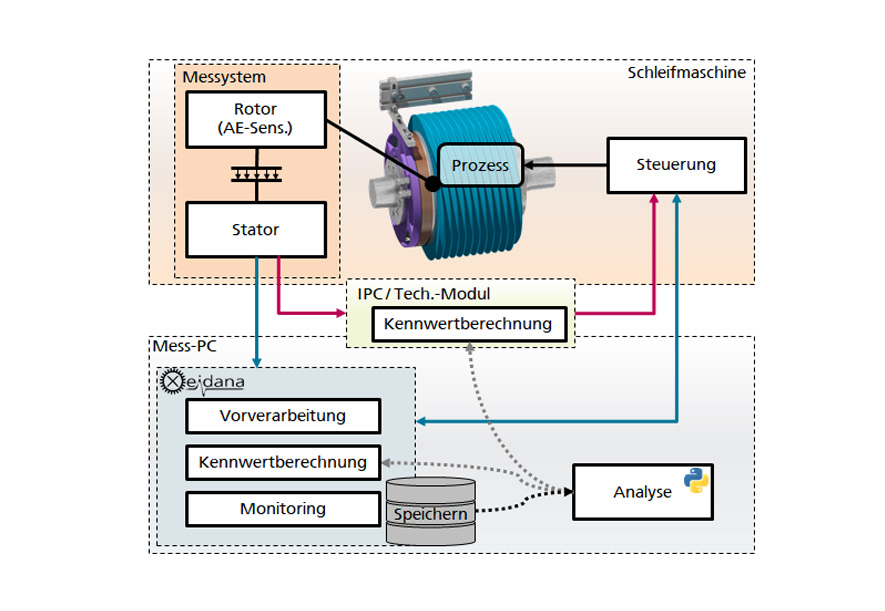

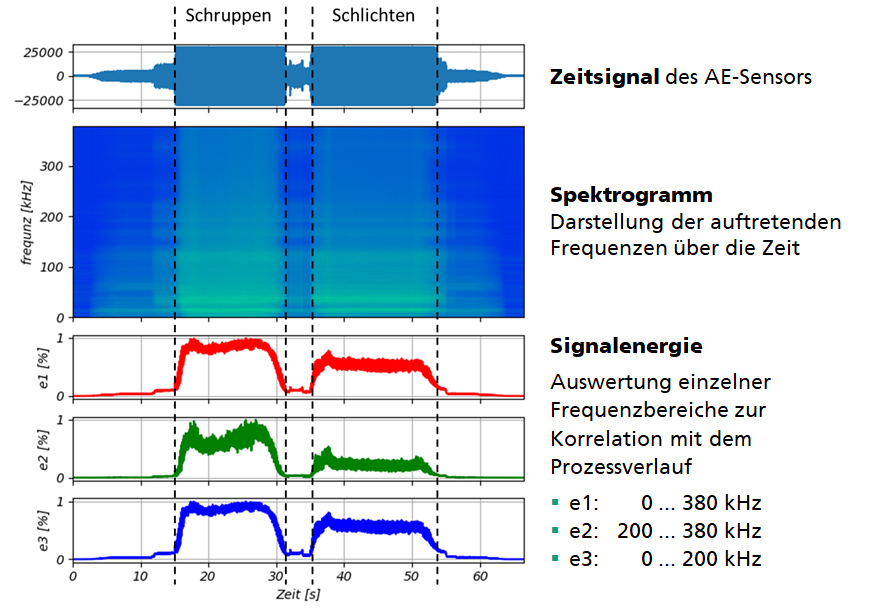

Process monitoring using Acoustic Emission offers a significant advantage over traditional measurement parameters such as spindle power or grinding force: it captures high-frequency vibrations caused by the cutting grain engagement. A newly developed measurement system directly couples the Acoustic Emission sensor to the grinding wheel. This minimizes disturbances from factors such as air locks, bearing noise, and drive noise, allowing for a more precise analysis of the grinding process.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology