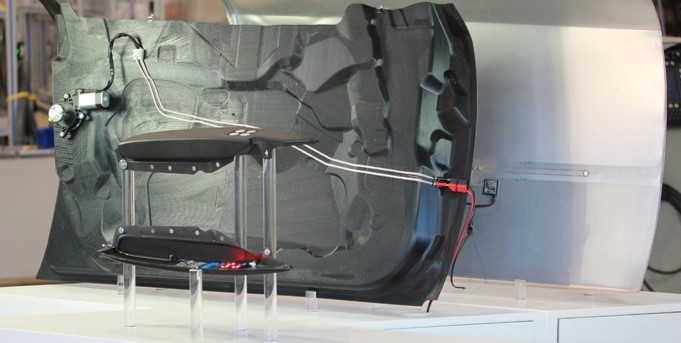

Smart Door – Printed sensors and wiring harnesses on vehicle door components (Go Beyond 4.0

Challenge

Digital printing processes, also known as functional printing, are rarely used in mass production for product customization. However, their use could allow series products to be adapted in a resource-efficient and cost-effective manner, even down to individual pieces.

A central challenge lies in the increasing density of sensors required in modern systems. Since many sensors need to be placed in hard-to-reach areas, assembly becomes particularly demanding. Additionally, the production of stable electrical contacts, usually realized through connectors or solder joints, is necessary. These technical requirements increase complexity and make cost-efficient integration of sensors into the production process difficult.

Solution

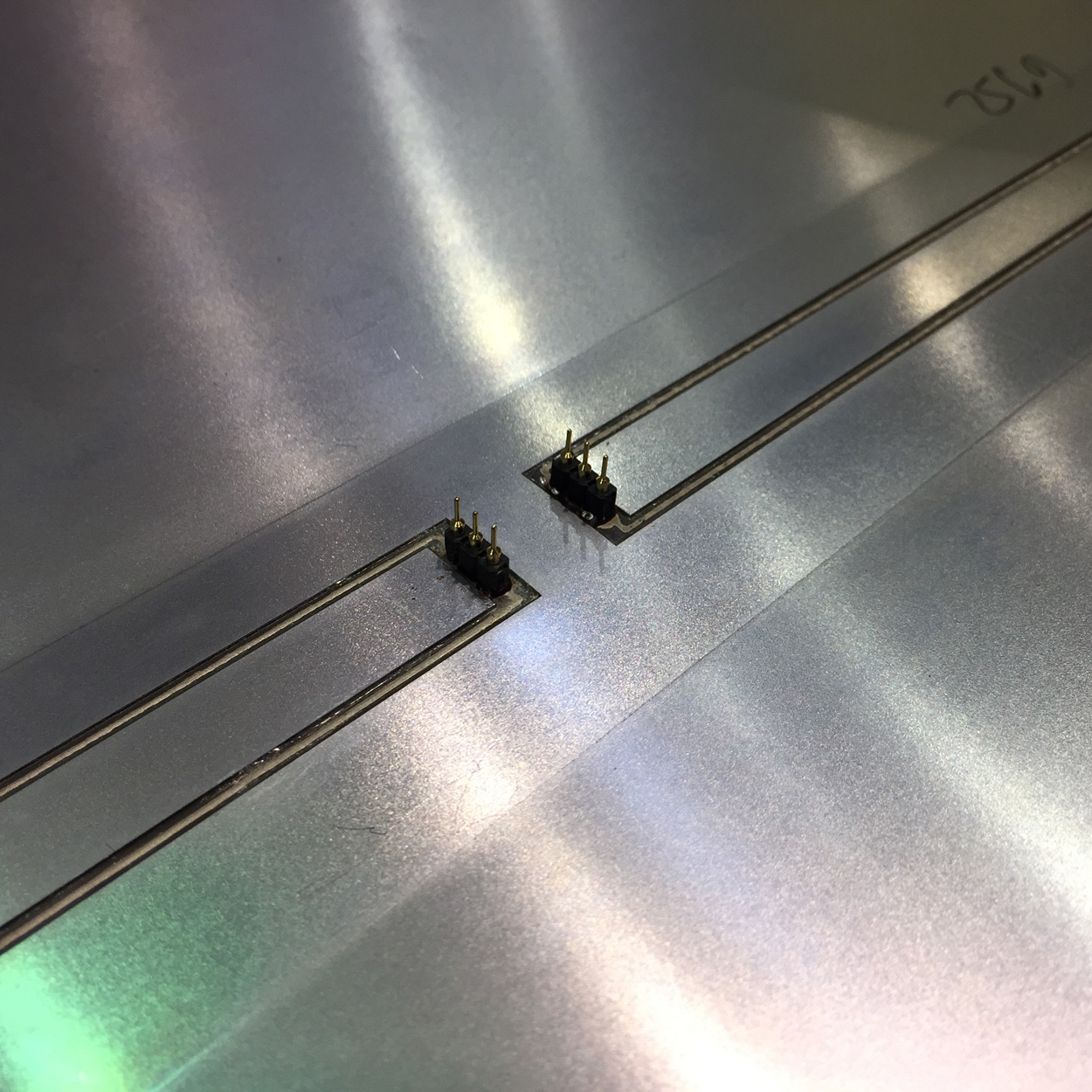

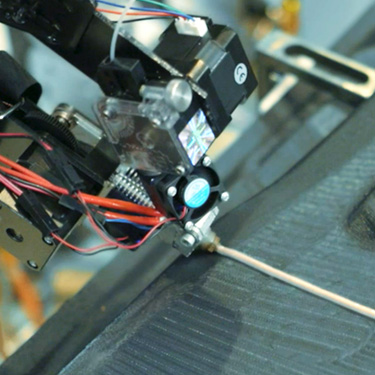

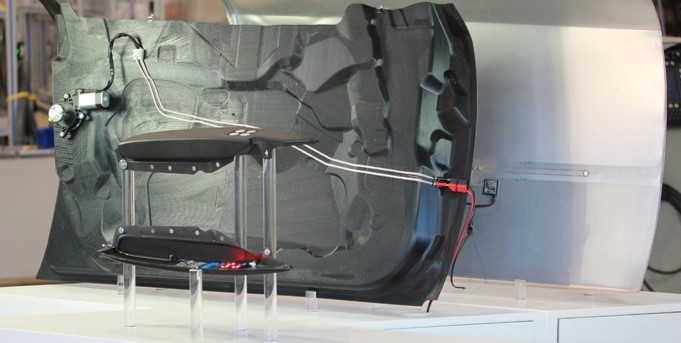

As part of the Go Beyond 4.0 flagship project, piezo-jet technology was successfully implemented to address key challenges in integrating sensors and circuit traces directly onto components.

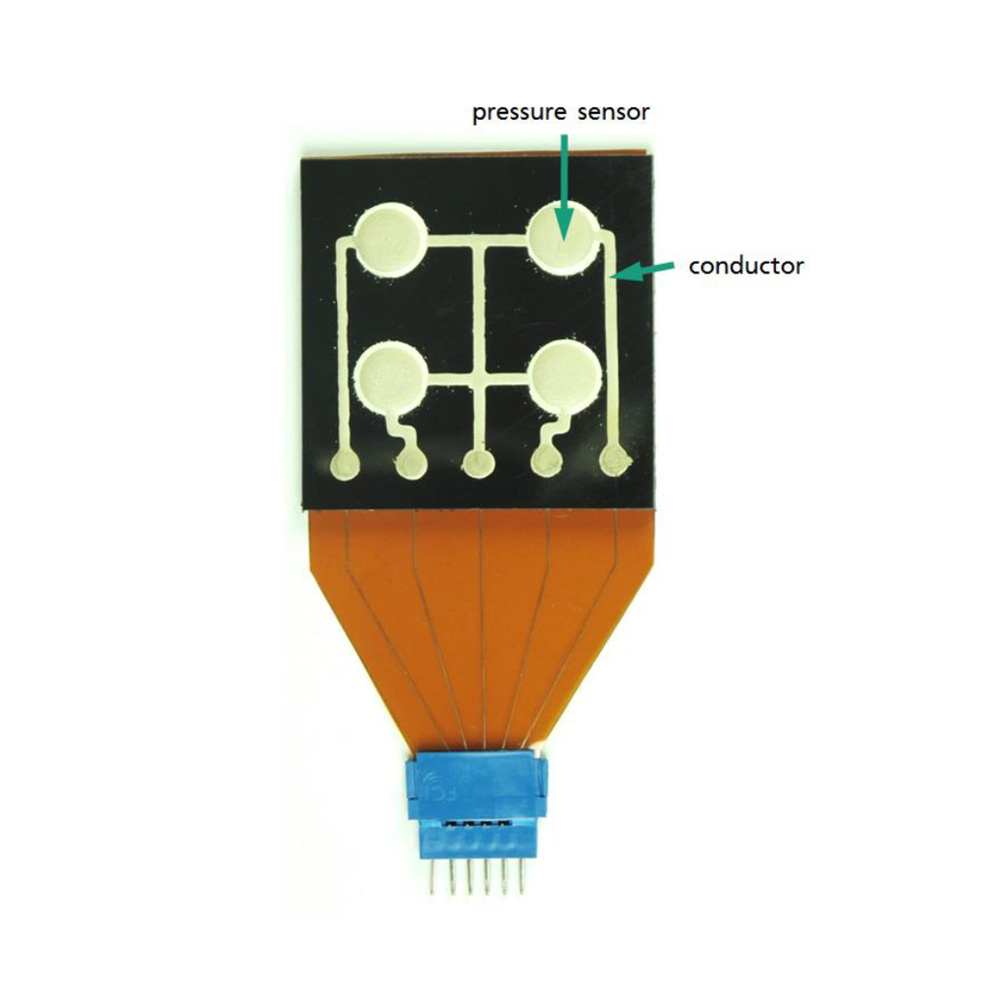

Significant progress was made through the project, including a fully printed control module for operating light elements on vehicle doors. This module includes both wiring and integrated force sensors, using silver paste for the circuit traces and a dielectric polymer paste for insulation to ensure optimal functionality and safety.

Additionally, the contacting and wiring for piezo elements and LEDs were successfully implemented, enabling robust and durable integration of these components into the overall system.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology