Polymer-metal 3D printing with hybrid material extrusion - Pompey

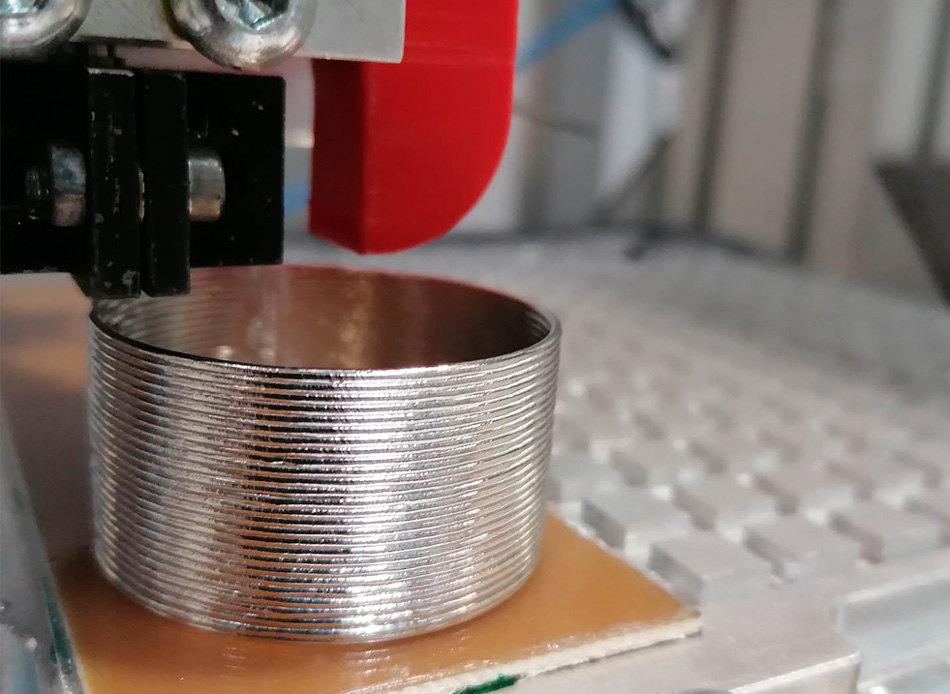

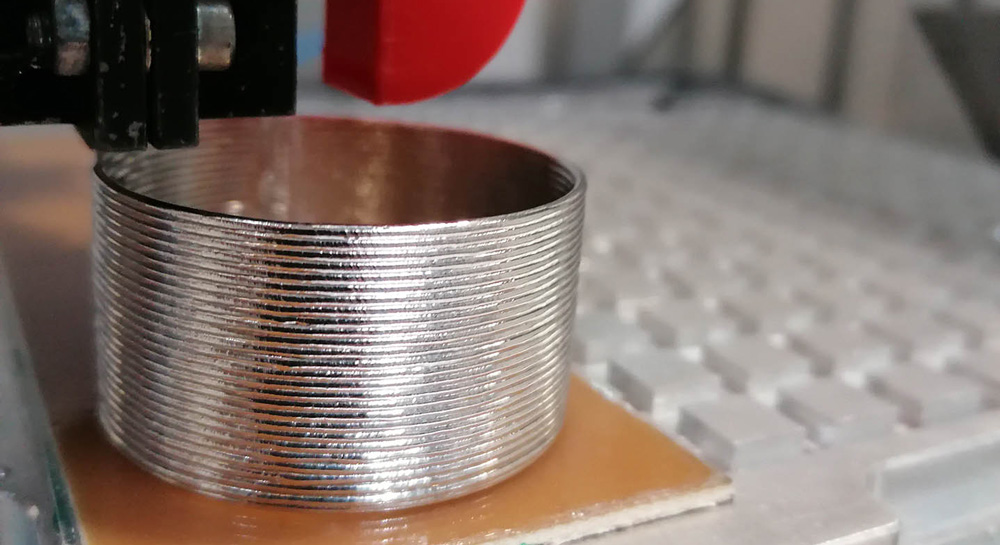

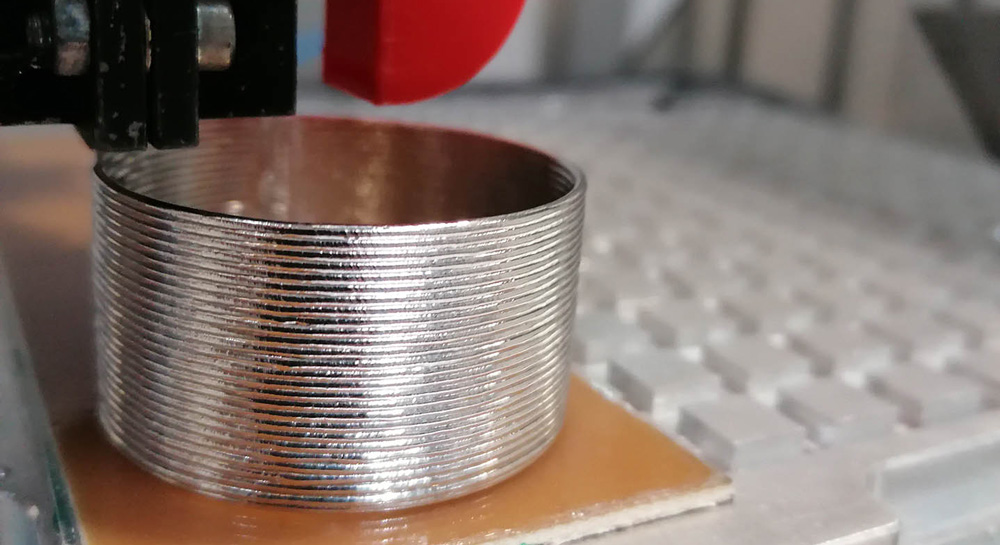

The Pompey project is developing an innovative multi-material approach to additive manufacturing based on the melt extrusion of polymer and metal materials. The aim is to produce multi-material parts with improved performance, reduced energy and material requirements and lower costs by using a newly developed hybrid manufacturing system. The tasks in the project include the investigation of the multi-material system of thermoplastics and low-melting solder joints, the development of the printing process and the design of a printer for multi-material processing. Comprehensive data acquisition during the process ensures high quality of the manufactured part and supports the establishment of a digital twin to accelerate further material and process development. The developed print heads will be integrated into an industrial 3D printer in the project and the technology will be validated by manufacturing a demonstrator with embedded electronic functionality and repairing an electrical circuit.

Video about the project

Key data for the project

Term

May 2022 – March 2025

Project Partner

- Omni3D Lid. Poznan / Poland

- TU Chemnitz, Institute for Machine Tools and Production Processes (IWP), Professorship Production Systems and Processes

- Fraunhofer IWU, Chemnitz (Coordinator)

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology