FutureFlexPro – Battery Module Construction

Challenges

The objective of the “Battery module construction” sub-project of the BMBF project FutureFlexPro was to redesign a battery module, taking into account cell geometry and arrangement, thermal management, fire protection and module disassembly. The design of the battery module was based on the materials and production technologies of the participating project partners Fraunhofer IFAM, IST, IWU and WKI. Lithium iron phosphate pouch cells in standard dimensions were used as cells. Less than 60 V was selected for the module voltage. A detachable module connection was developed for the interface between the module and the battery housing to facilitate quick and easy disassembly. This was intended to meet the increased requirements for ease of repair, maintenance and disassembly. Due to the variety of the individual technologies and competencies that were considered in the processing environment of the battery module, a large part of the processing within the project took place at sub-component and material level. The results were incorporated into the overall design, which was developed jointly by Fraunhofer IWU and IFAM. This provided an excellent starting point for the implementation of the battery module demonstrator at the end of the project.

Solution

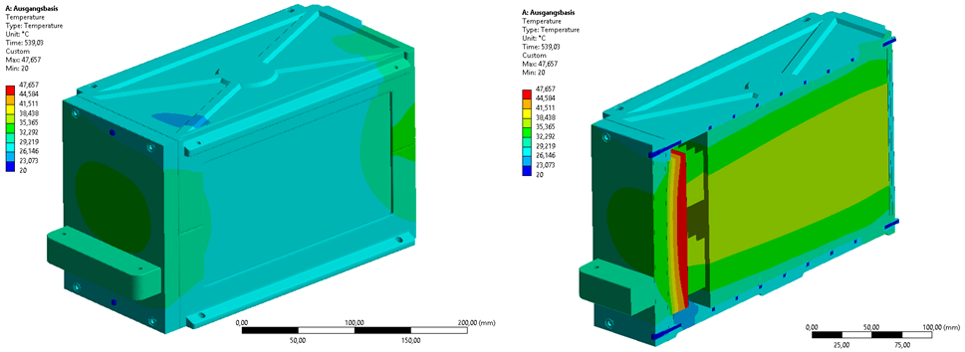

In addition to the development and implementation of suitable design principles, one of Fraunhofer IWU's declared project objectives was the integration of passive thermal storage elements directly into the module. The focus here was on phase change material (PCM), which was embedded in porous metallic structures. Kerosenes were selected as PCMs on the basis of their properties (such as corrosion behavior). A multifunctional support structure consisting of an aluminum foam sandwich and integrated thermal buffer material was developed based on the module component lid. An aluminum foam sandwich bumper is placed on top of this to protect the module from lateral crash and crush loads. The PCM with its low thermal conductivity was integrated directly into the aluminum structure, which acts as a heat-conducting matrix to ensure sufficiently rapid heat transfer to the storage material. The power electronics were placed on the back of the lid. Depending on the load, this generates heat quantities that result in a temperature increase in the power electonics and any adjacent parts. The thermal behavior for the fast charging load case was also examined at system level.

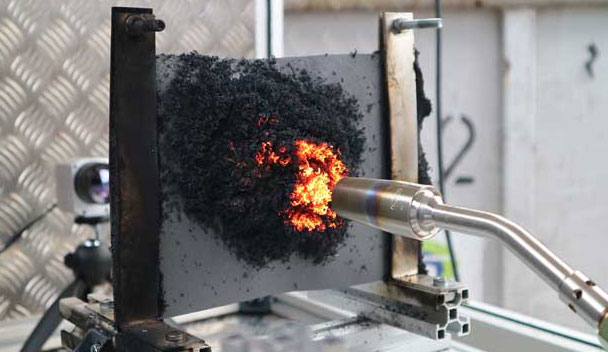

Another focus of the project was the investigation and implementation of suitable fire protection measures. To this end, a test rig was developed and set up to characterize various materials and material combinations in terms of fire resistance.

Insight into the Project

© Fraunhofer IWU

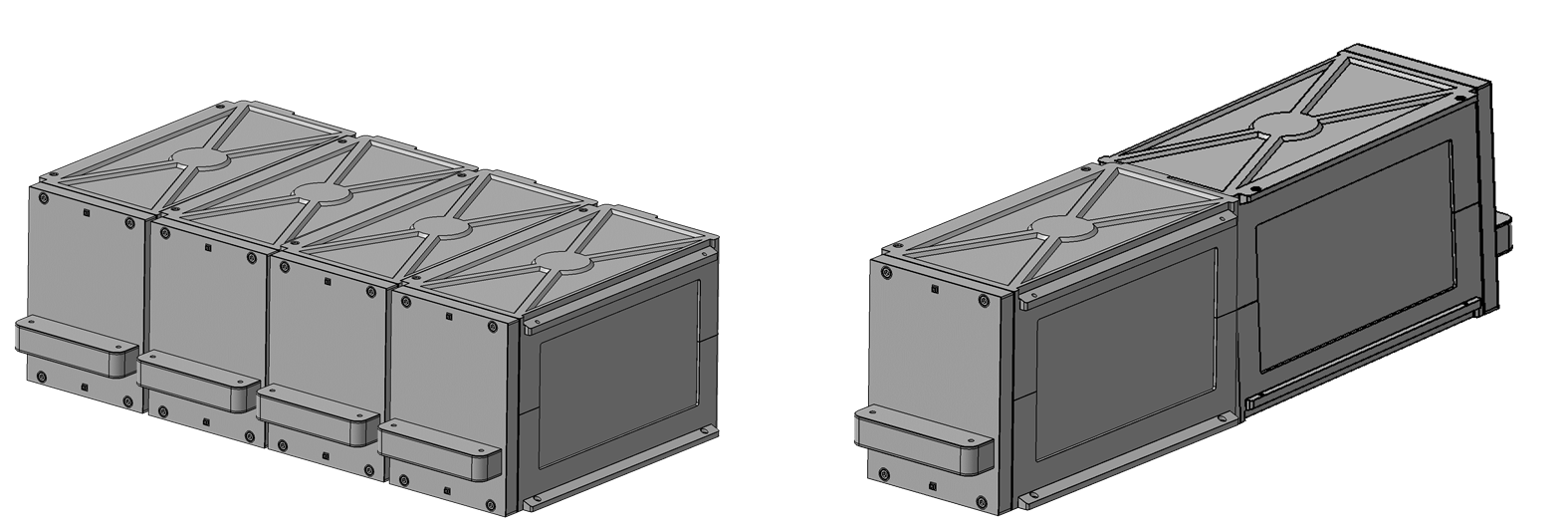

Demonstrator of the function-integrated battery module

Key data for the project

Term

March 2021 until December 2021

Coordination

Fraunhofer-Zentrum Circular Economy für Mobilität CCEM

Project Partner

Fraunhofer IWU, IFAM, WKI, IST, IAO

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology