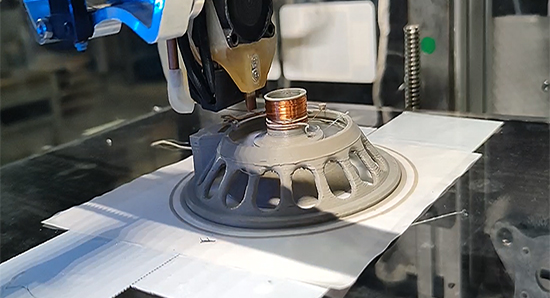

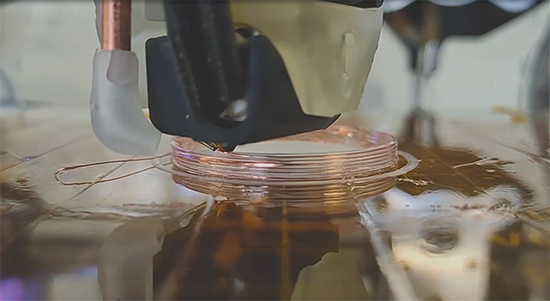

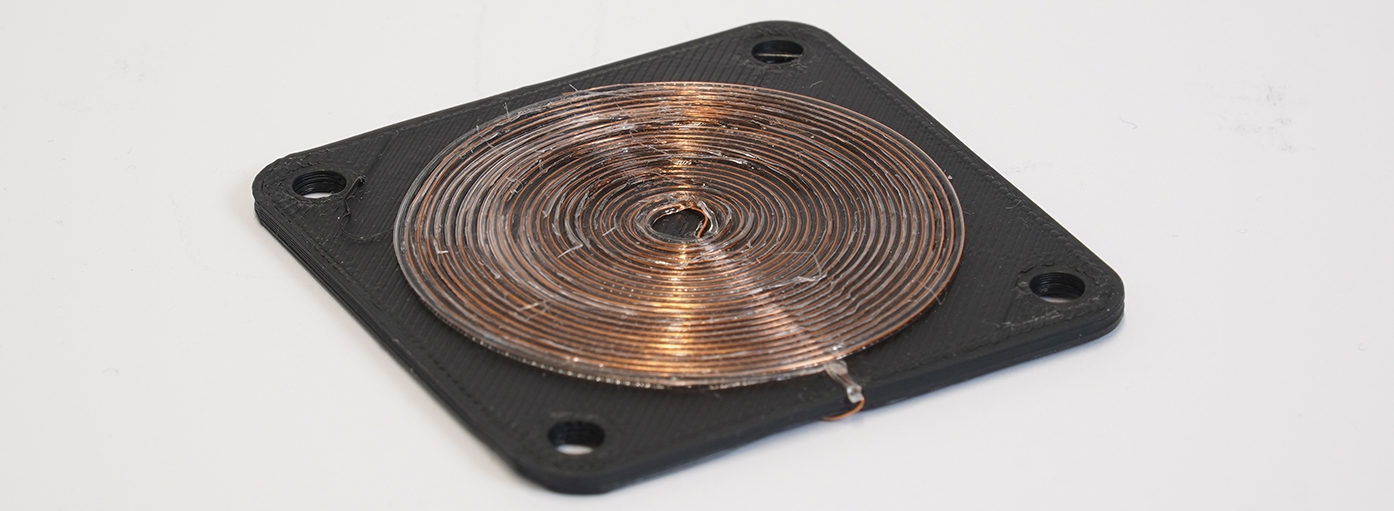

Custom-printed actuator coils

Challenge

Coils are used in numerous applications, whether as inductors, sensors, antennas, or actuators. They are thus an essential component of various products. Our research focuses on the customized production of coil elements for use in speakers, electrodynamic actuators, contactless information transmission, and integrated sensor technology. In this context, shape, winding density, and materials are crucial influencing factors that are evaluated and optimized.

Solution

The WEAM process enables the construction of a theoretically unlimited number of coil windings through rotational decoupling. Thanks to the free choice of materials, we can fully automate the integration of coils into various environments. The additive component of the WEAM process allows for the creation of any coil contours to achieve targeted field line densities. Our research technology offers the possibility to quickly and cost-effectively produce components in quantities from 1 to 100, ranging from individualized standard coils to complexly shaped special coils.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology