Fraunhofer Institutes Establish New Branch for Aviation Research in Cottbus

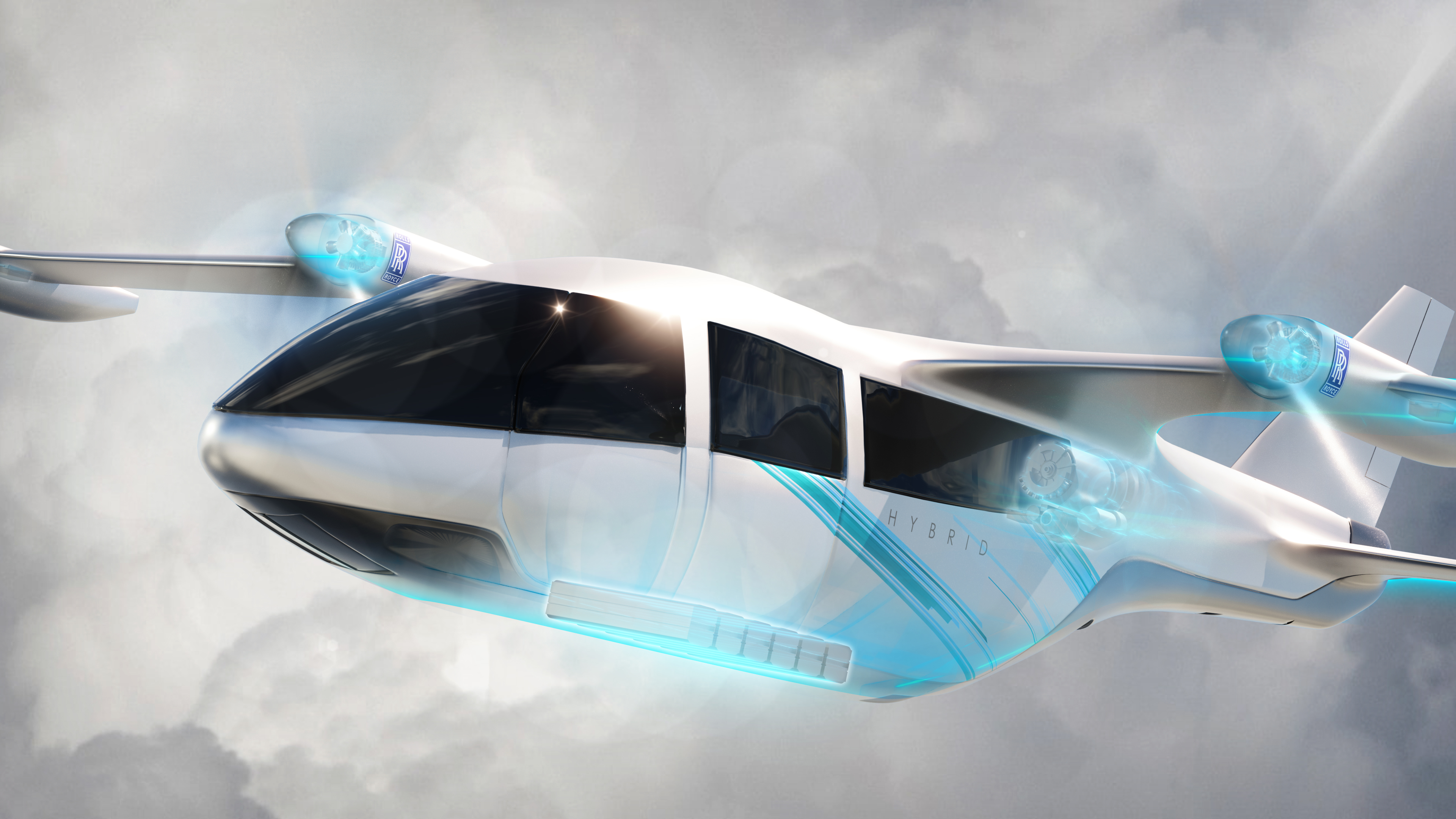

Thrust for Hybrid Electric Flying

Several Fraunhofer Institutes and the Brandenburg Technical University Cottbus-Senftenberg, under the leadership of Rolls-Royce Germany and other partners such as the research institution ACCESS, are collaborating on the future of hybrid electric flying. Supported by the state of Brandenburg and the Federal Ministry for Economic Affairs and Climate Protection, the partners are researching an entirely new propulsion system for medium-range aircraft with up to 35 passengers.

The Clean Sky programs of the European Union and the Clean Aviation perspectives within them serve as important guidelines for the industry on the way to a significant reduction of nitrogen oxide and noise emissions caused by aviation. A promising technology for this purpose is hybrid electric flying: a gas turbine generates electrical energy, which charges intermediate battery storage; the aircraft draws its electrical energy from this storage for propulsion. This technology banks on larger, slower rotating rotors that produce less noise on the ground, creating a significantly smaller noise footprint than conventional propulsion aircraft. The modular structure of the proposed concept also allows for the future use of alternative fuels or entirely new power sources.

By mid-2026, the partners aim to develop manufacturing technologies for hybrid electric propulsion components, qualify existing technologies, and produce prototype components. The focus is on accelerating the development and delivery of prototypes in a sector characterized by high competition. An example is the project's goal to significantly shorten the lead times from the finished design of a functional prototype to handing it over to the client, reducing them from several months to a few weeks. Other projects involve creating highly flexible production concepts essential for efficient mass production. These projects open the perspective of attractive jobs in Cottbus and the Lausitz region, ranging from developing state-of-the-art propulsion systems (not only in aviation) to industrial production.

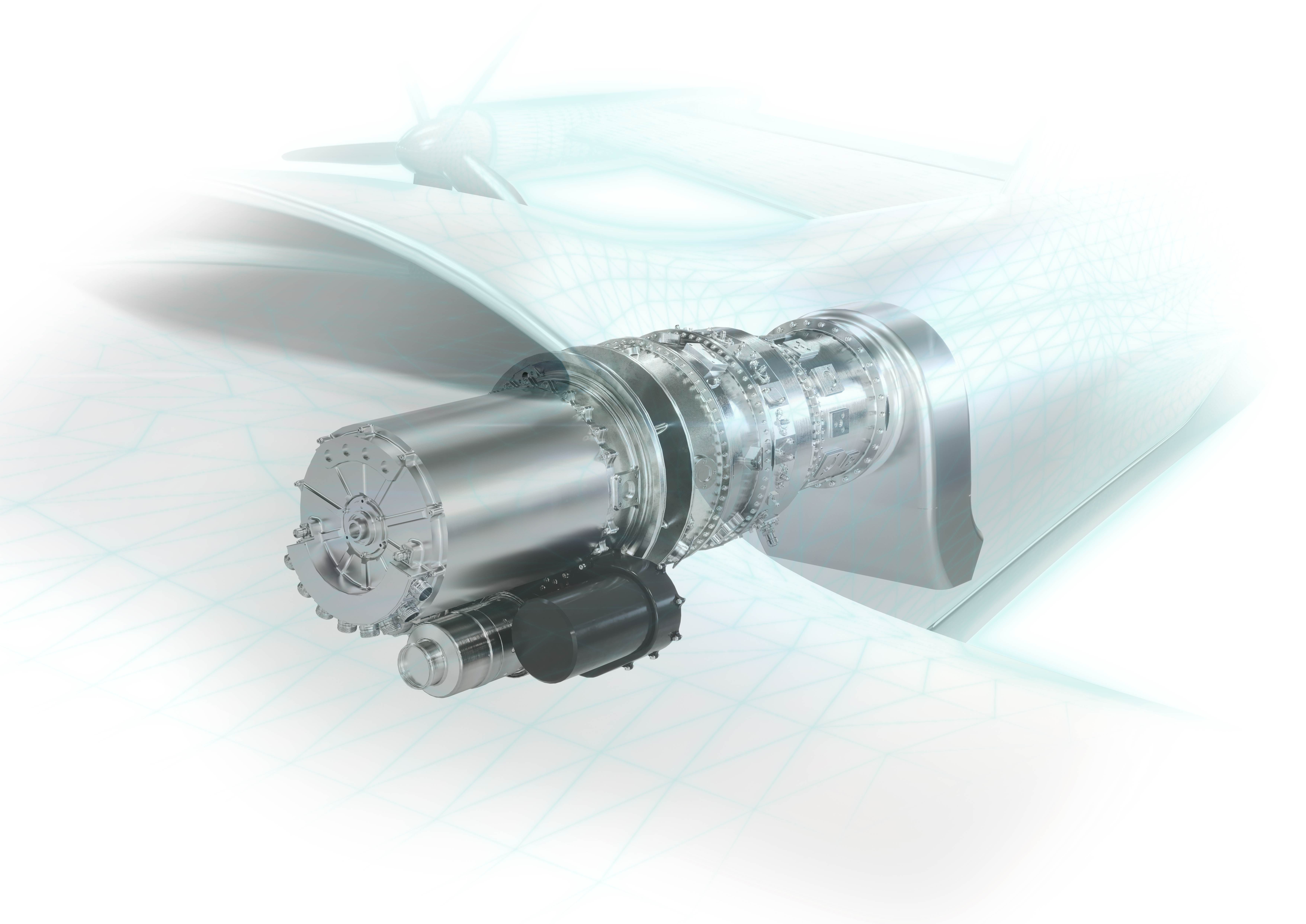

Each of the participating Fraunhofer Institutes contributes its specific expertise to provide solutions for the aircraft manufacturer's later serial development. Numerous planned production technologies, such as additive manufacturing (3D printing) and forming, have not been applied in aircraft construction before; qualifying them for this industry with its particularly stringent requirements for quality, reliability, and durability is a challenge that the institutes are now addressing. The high interdisciplinarity of the research projects requires utilizing the competencies of multiple institutes and discussing technical issues synergistically. One key component involving multiple institutes in its development is the combustion chamber of the gas turbine.

The Fraunhofer Institute for Machine Tools and Forming Technology IWU has built a reputation for developing cutting-edge manufacturing processes and production systems. It takes on the coordination role among the research partners. Fraunhofer IWU, relying on its expertise in forming technology and high-performance machining, is involved in production processes for the combustion chamber housing via bulk-forming and flexible component machining. Another focus is the arrangement or geometry of wire windings (coils) in electric drives that enable a more efficient operation or higher torque. Fraunhofer IWU specifically supports the indispensable, continuous digital representation throughout all sections of the development cycle to serial production for successful project completion.

The Fraunhofer Institute for Material and Beam Technology IWS focuses on laser-based additive manufacturing. In Direct Energy Deposition (DED), metal is melted and subsequently welded where needed. This technology allows to print components of up to ten meters in length freely in shape and size. Fraunhofer IWS privileges Laser Powder Bed Fusion (PBF-LB) as the best method for manufacturing the combustion chamber. In this process, a laser melts metal powder layer by layer onto a component. Cooling holes are inherently spared during printing, saving material.

The Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM further develops a specifically innovative metallic 3D printing process established by the Israeli company Tritone Technologies Ltd. MoldJet® combines two manufacturing processes that work alternately for layer-wise component manufacturing. In the first layer, the form is produced as a negative to the component geometry from a wax-like polymer using inkjet print heads. This printed layer of form material is then filled with metal powder paste through a slot nozzle and a squeegee. Due to the layer-wise construction, it is possible to manufacture complex components with undercuts or internal channels without support structures.

No gas turbine is complete without cast components such as turbine blades or housings. ACCESS e.V. is responsible for the development of these cast components. At its Cottbus location, established in 2021, ACCESS refines the latest additive processes to accelerate the complex precision casting route. The goal is to develop tool-free precision casting parts – in a shorter time, at lower costs, but with greater design freedom.

The Center for Hybrid Electric Systems (chesco) at the Brandenburg Technical University Cottbus-Senftenberg (BTU) takes on development tasks. It will coordinate future orders for research and development projects granted by Rolls-Royce Germany to the Fraunhofer Institutes, for example. Simultaneously, chesco will ensure that competence for future series production of hybrid electric passenger aircraft will be available in the Brandenburg Lausitz region.

Fraunhofer IWU, IFAM, and IWS: New Cottbus Facility

The new facility on Siemens-Halske-Ring is located on the BTU campus and, thus, close to BTU and chesco. The operational coordination with the already established Fraunhofer Institutes in Cottbus also benefits from the presence of the three institutes in the Brandenburg Lausitz region.

Rolls-Royce Germany

Rolls-Royce develops and delivers complex energy and propulsion solutions for safety-critical applications in the air, on water, and on land. Rolls-Royce Germany has been present with own locations in Germany since 1990 and is active in the aviation industry. Within the group, Germany, with around 10,000 employees at a dozen locations, has the second-largest workforce after the United Kingdom. Rolls-Royce Germany is the only German aircraft engine manufacturer authorized for the development, production, and maintenance of modern civil and military turbine engines.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology