New Momentum for the Linked Factory

EmulDan reduces Energy Consumption in Forming and Machining by up to 20 Percent (on average)

EmulDan stands for ‘Energy Efficiency in Production through Multivalent Data Usage.’ In this joint project, the Fraunhofer IWU and its industry partners demonstrated that significantly lower consumption process routes are achievable while maintaining component quality, leading even to shorter processing times in some cases. Moreover, when process design is consistently energy-efficient, maintenance efforts for production equipment also decrease. EmulDan focuses on how to collect data, providing valuable insights for both AI-based models and improved manual control options.

Data is the gold of Industry 4.0: It is essential for controlling machines and systems in highly specialized processes. Sensors monitor these processes, generating large amounts of new data. Data collected at the points of action is particularly interesting for AI and machine learning applications when it can be aggregated, transformed into a unified data model, and analyzed profoundly. Only then can this data be used to create value, leading to continuous improvement in production.

'Linked Factory': Connected Machines, Customized Information

The Linked Factory data architecture is a vision developed by Fraunhofer IWU for a comprehensive digital representation of all products, processes, and machines within companies. This framework enables the integration of individual machines, logistics processes, and building management systems. As a central element, a knowledge graph permits connecting different data to generate real-time information. Extracting information from large volumes of data properly means that individual data packets should support employees in their tasks rather than add to their burdens. 'Contextual delivery' is the key phrase here, as the information needs of production managers differ from those of machine operators or maintenance technicians working on repairs. Therefore, each employee gets information tailored to their specific responsibilities. Central challenges in achieving a perfectly connected factory include intelligently linked controls and suitable interfaces to ensure all relevant data is extracted and fed back accurately.

For updates on the Linked Factory, visit GitHub.

EmulDan: Foundation for Informed Decisions and Machine Learning

Alongside data architecture, the AI models developed in EmulDan represent a significant step toward comprehensive digital twins. In manufacturing areas with low automation levels, these machine-learning applications can optimally support planners, decision-makers, and production staff in their decision-making processes by highlighting trends. For example, 'drifts,' where the manufacturing of a component approaches tolerance limits, can be detected earlier.

In EmulDan, project partners focused on energy efficiency, ensuring that traditional metrics such as manufacturing time, cost, and product quality did not deteriorate. Results achieved are now visible in demonstrators that highlight significant energy-saving potentials in manufacturing processes for hot forming, cold forming, and machining.

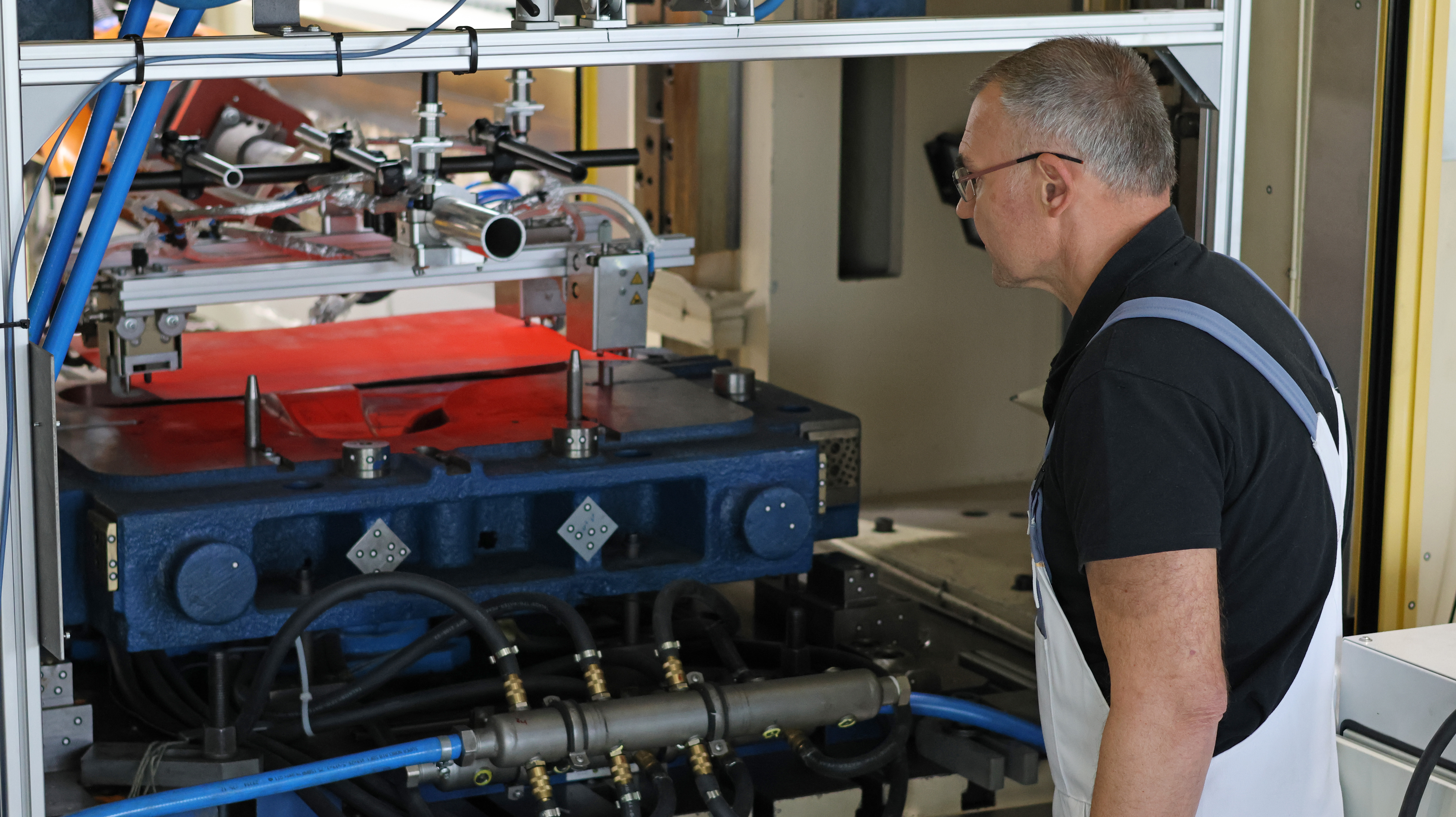

Press Hardening and Hot Forming

Press hardening combines the advantages of forming and heat treatment in a single step. It enables the production of high-strength, lightweight body parts, such as B-pillars in automobiles. In the project, a boron-manganese sheet was heated to over 900 °C and then formed and cooled in a die. The rapid cooling during and after forming transforms the material structure into a martensitic form, resulting in high hardness and strength. This manufacturing process consumes a lot of energy, so exploring saving opportunities is logical. For data-driven process control, project partners collected all relevant manufacturing data from individual processes and process chains and created process models to predict energy needs and component quality across various optimization scenarios. Hybrid process models based on digital twins proved particularly beneficial, resulting in potential energy savings of up to 20 percent by combining several adjusted process parameters.

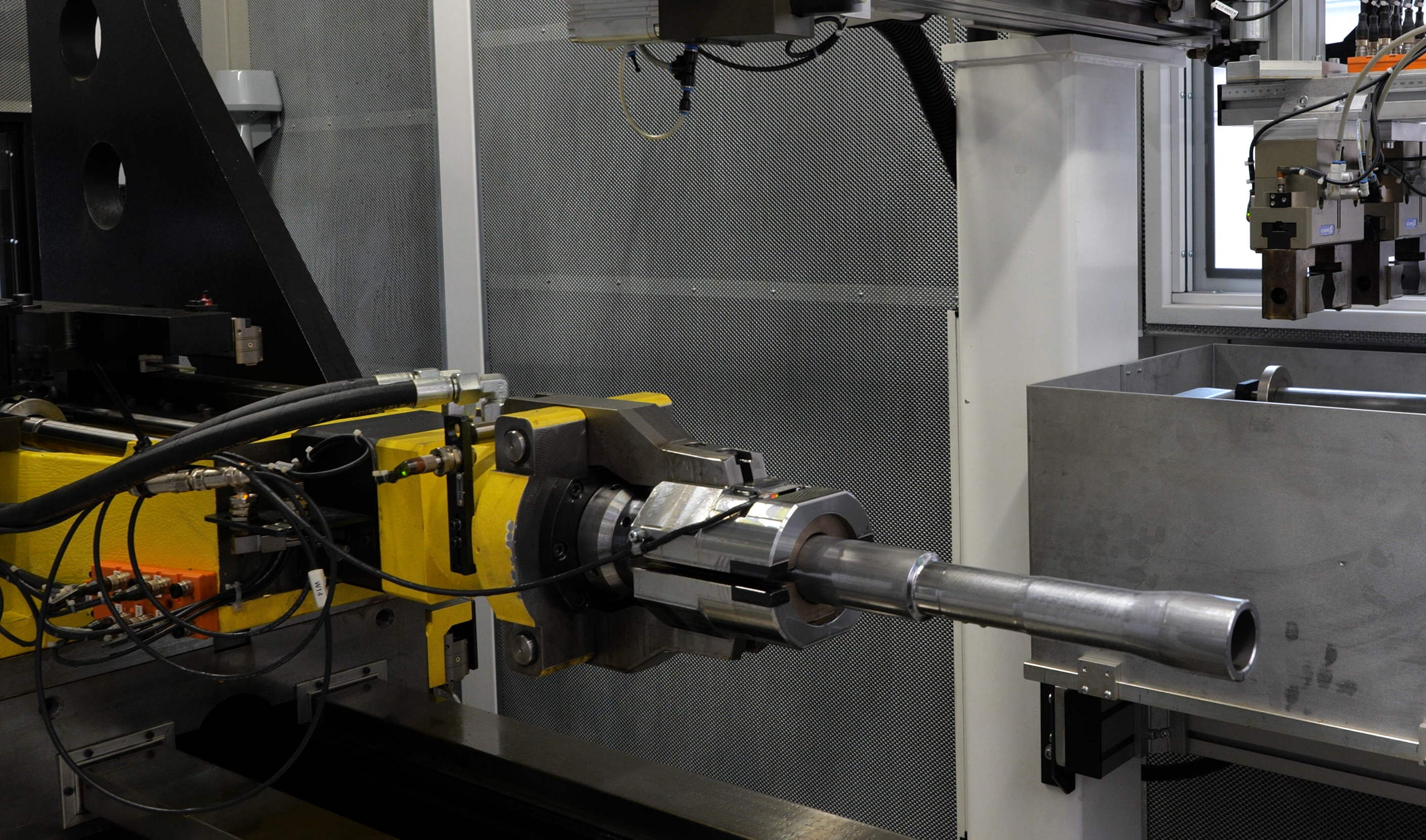

Cold Forming with a Round Bar Knurling Machine

Round bar knurling machines are a natural choice for the efficient, non-cutting production of lightweight components. The fundamental principle of round knurling involves a cyclical motion of several tool segments acting radially on the workpiece in rapid succession. This processing makes the material plastically deformable, allowing for complex, preferably rotationally symmetrical geometries.

Round knurling is suitable for producing various shapes. Typical applications in the automotive sector include steering spindles, drive shafts, and airbag cylinders; round knurling is a suitable production method for high-precision manufacturing of components for aircraft engines or landing gear, too.

EmulDan also demonstrated significant energy-saving potential for this forming process. The partners focused on supplementing the previously unregulated, primarily quality-focused, experience-based process parameters with energy-relevant aspects.

This approach helped design a software tool for data processing that enables self-learning process correction and creates suitable models for forecasting. It identifies relationships between machine parameters, component quality, and energy-related process metrics, translating them into process models that aim for overall optimization.

In practice, this means better process understanding and the potential for energy consumption reductions of up to 70 percent.

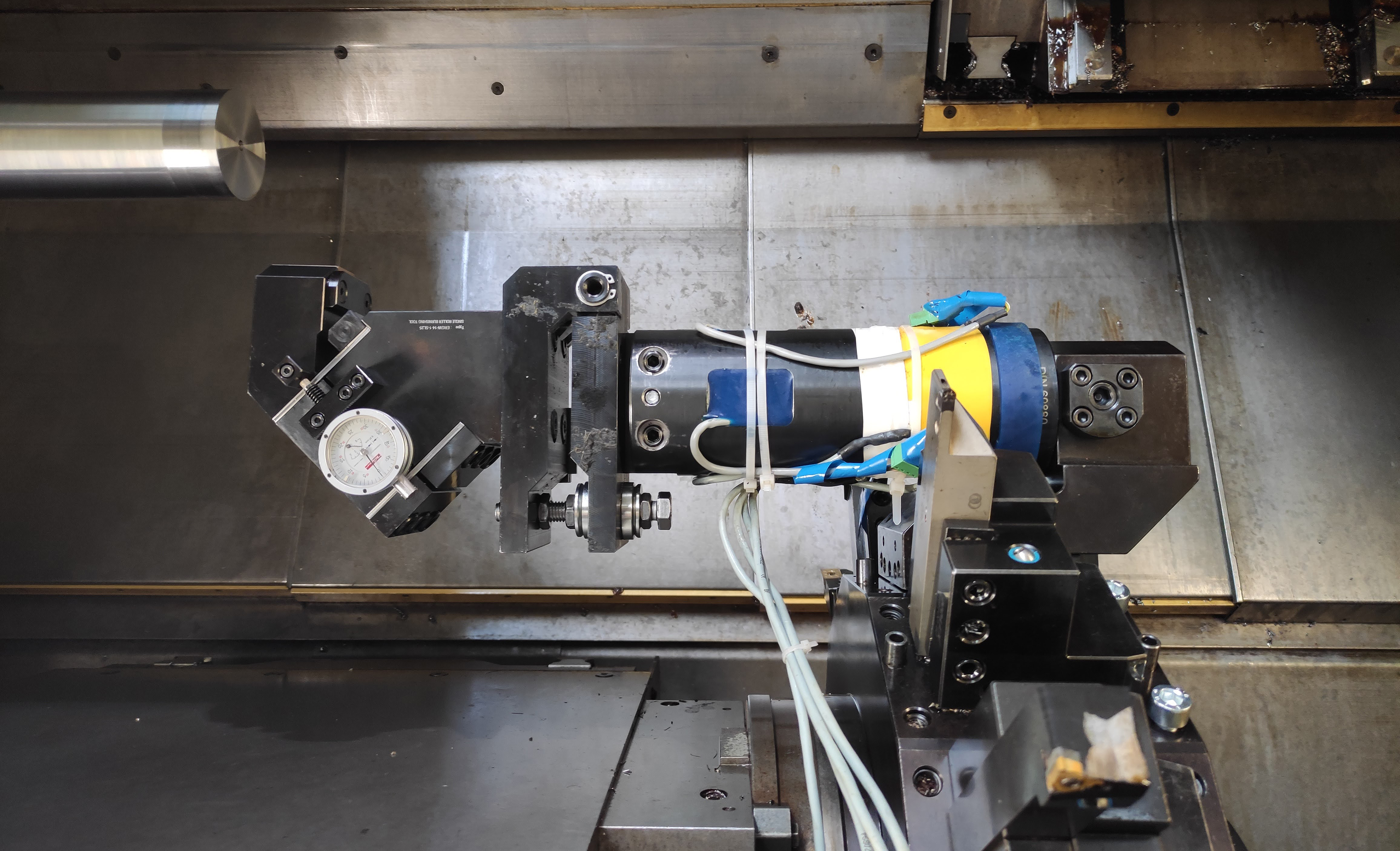

Turning and Rolling Processes

In processes such as turning and smoothing, high safety factors often guarantee that components comply with specifications and can be produced even under unfavorable conditions. In EmulDan, sensors integrated into tool holders provided data for assessing tool conditions and processes, forming the basis for significantly reducing many safety factors. Adaptive processes that build on the captured measurement signals can leverage such potential. Control occurs during turning through feed rate; when smoothing, delivery (rolling force) ensures control. The project partners demonstrated that a main times reduction of 50 percent is feasible. As a positive side effect, much testing becomes obsolete, and process reliability increases.

Project partners of Fraunhofer IWU in EmulDan include: AutoForm Engineering Deutschland GmbH, Autotech Engineering Deutschland GmbH, FORCAM GmbH, GT-Industrie-Service, HSP Schwahlen GmbH, ICM Institute for Chemnitz Mechanical Engineering and Plant Construction e.V., ROUNDTEC GmbH, VELOMAT Messelektronik GmbH, and Wenaroll GmbH tools and systems.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology