Fraunhofer IWU at Formnext, November 7 - 11, 2023, Fraunhofer joint booth Hall 11 Stand D31

Metal 3D Printing at Fraunhofer IWU: Delicate Implants, Sophisticated Heat Exchangers, Highly Durable Wheel Carriers

Additive manufacturing technologies enable an almost limitless variety of products with increasingly demanding materials and 'embedded' functions. Laser Powder Bed Fusion (LPBF) allows tremendous freedom in material selection, geometry, and integration of functions. Current research focus at Fraunhofer IWU: revolutionary printing strategies for high-quality medical implants and ultra-thin, highly efficient heat exchangers that utilize valuable waste heat. 3D-printed aluminum wheel carriers can be both highly durable and economically manufacturable.

Delicate lattice structures with integrated function; Premiere for new exposure strategies enabling particularly high-quality implants

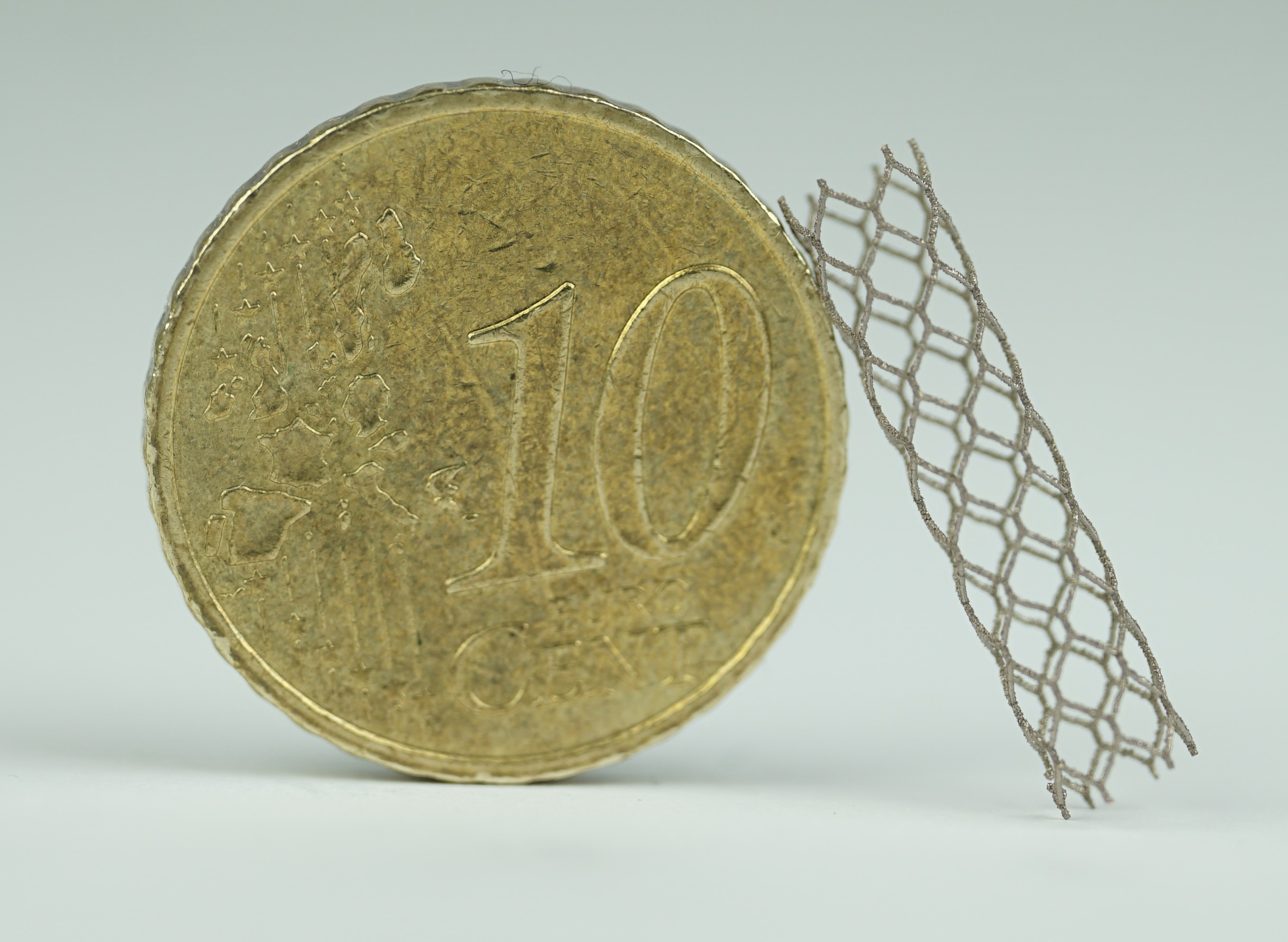

Thanks to LPBF, it is possible to integrate functions into sophisticated products and produce them at reasonable cost in small and medium quantities - without complex supply or process chains. The two options to achieve functional integration are integrating sensors or actuators, or processing so-called functional materials. This results in a fascinating variety of applications and products with highly utilizable value. Researchers at Fraunhofer IWU are increasingly addressing the needs of medical technology. One of their research topics is implants with delicate lattice structures like stents that keep clogged blood vessels open, especially around the heart or in the brain. For gentle implantation, it is advisable to use so-called superelastic shape memory alloys (SMA) that fully expand only when they reach the narrowed blood vessel. During transport through the catheter, the stent is elastically highly 'folded,' allowing the catheter to be thin, making the procedure particularly gentle (minimally invasive). Once in place, the stent returns to its original shape. The lattice structure of the stent enables both compact transport and permanent stabilization of a design made of wires that are only 100 - 200 micrometers (0.1 - 0.2 millimeters) thin.

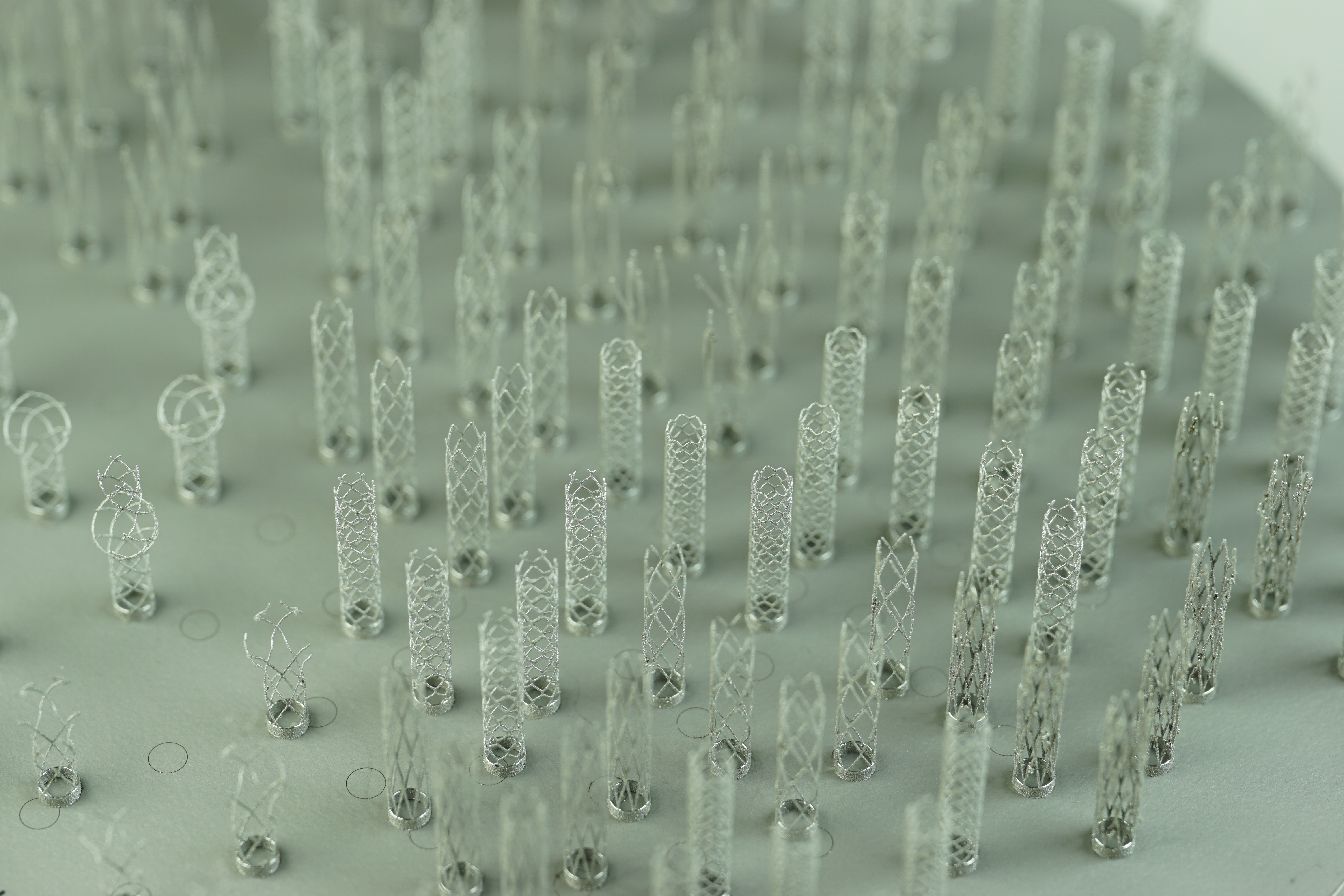

Manufacturing stents in the LPBF process minimizes waste: spaces between the lattices are not printed along, whereas spaces in a cylinder produced in forming technology must be cut out in another process step with a precision laser.

The printing technique also allows for the production of stents with different geometries in the same batch. For example, it is possible to print stents for cerebral aneurysms (stroke) according to the needs of individual patients. Since pathological protrusions in the vessels are individually shaped, such customized products can help reduce the risk during the procedure and improve the chances of healing.

In cooperation with the Chair of Virtual Product Development at the Technical University of Dresden, the Fraunhofer IWU team currently focuses on new exposure strategies that further improve the quality of printed stents. In the LPBF process, metal powder is applied in many layers, with the laser melting the material precisely where the component is to be formed. The way the laser moves over the powder material is determined by the exposure strategy. When it comes to stents, the goal is to print rods that describe a circle or ellipse in cross-section, depending on their orientation. When the laser is perfectly parameterized for optimized laser paths in terms of speed, power, and focus diameter, much more precise results are achieved, especially for delicate components: the energy input is homogeneous in every layer and section, and there are hardly any attachments. Additionally, productivity increases significantly as the laser requires much shorter distances.

Heat Exchangers: Maximally effective with thin-walled, multi-curved structures

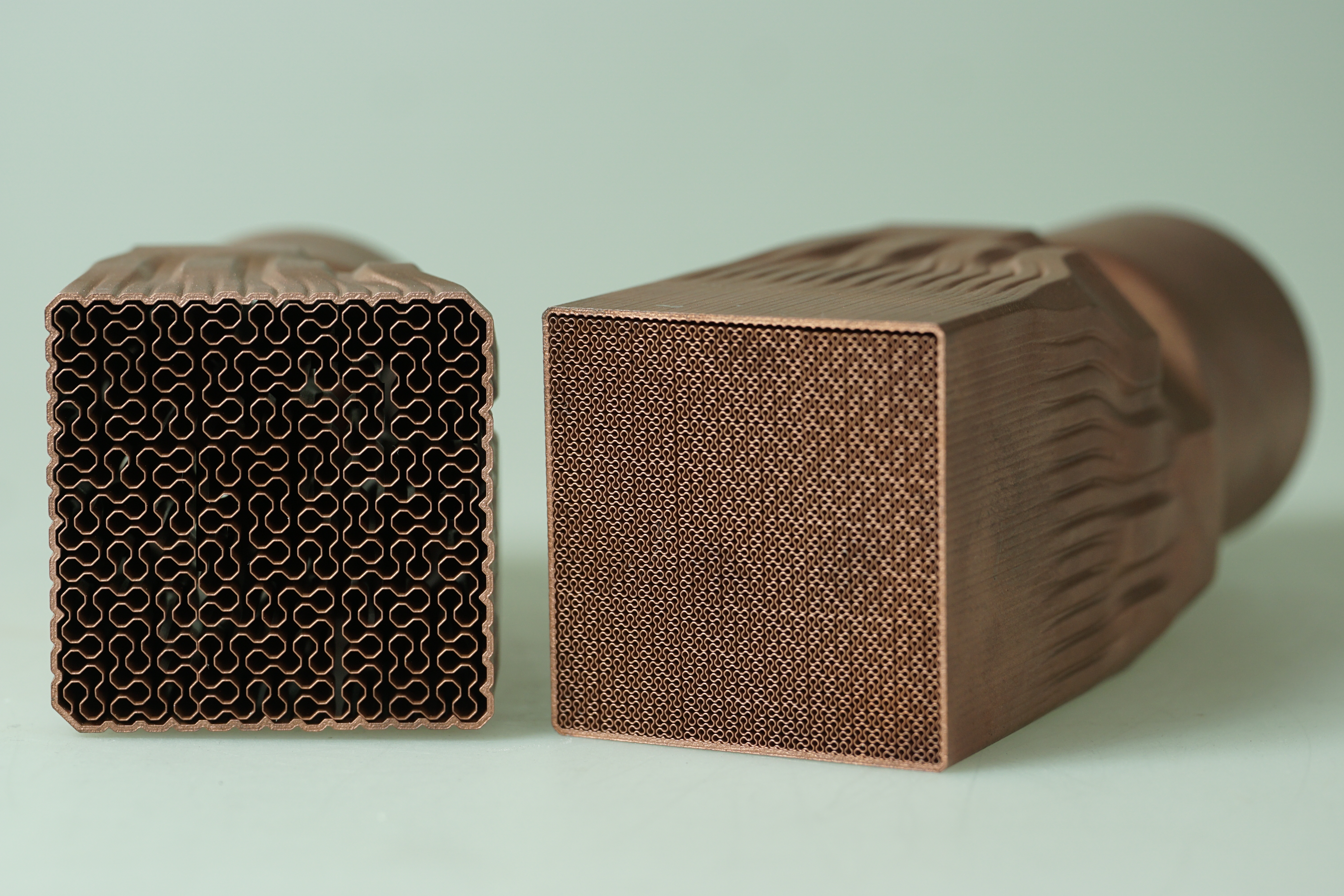

Heat exchangers are essential for the targeted transfer of thermal energy from one medium to another. Given the vast number of potential applications, these components need individual design according to their intended purpose and location - in terms of heat transfer performance, pressure resistance, and geometry. Only in this way can they deliver optimal performance for a given application. The efficiency of the heat exchanger often has a significant impact on the overall energy balance of the system.

Additive manufacturing processes are well suited for application-optimized, highly efficient heat exchangers. Thin-walled and large, multi-curved surfaces for heat transfer enable significant efficiency improvements. Metallic 3D printing using the LPBF process takes advantage of inherent design freedom for the rapid and resource-efficient production of such wall structures. Performance parameters in fluid-based applications, such as high-temperature heat exchangers and vapor chambers, greatly benefit from these structures - which are easily realizable through 3D printing. Moreover, high-temperature applications often require very resilient materials - which are being processed economically through LPBF.

This project is funded by the European Union under the Grant Agreement No. 101102316.

Printed aluminum wheel carriers: Highly resilient and economically manufacturable

Within the scope of the Campus FreeCity project for a networked fleet of modular robotic vehicles, the EDAG CityBot is being developed as a multifunctional robotic vehicle. It consists of a tractor and variable additional modules. After a test phase, it is foreseen particularly for passenger transport or cleaning tasks. In collaboration with Fraunhofer IWU and Constellium, EDAG Group has elaborated a streamlined process chain from rapid component development to selecting suitable manufacturing processes and materials, with an automated engineering approach. One example is the wheel carrier component, which connects the wheel to the chassis and steering motors. Different transport tasks and corresponding loads demand a customized component design. Laser Powder Bed Fusion (LPBF), in combination with the aluminum alloy Constellium Aheadd® CP1, proved to be economically and technologically advantageous - in terms of processability, production speed, and mechanical properties of the product. Fraunhofer IWU subsequently developed the LPBF process parameters for a standard industrial printer. Soon, the CityBot will undergo practical testing at the Deutsche Bank Park in Frankfurt am Main. The German Federal Ministry for Digital and Transport provides funding for the Campus FreeCity project.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology