Here you can find our press information and high-resolution images for your editorial reporting. Publications about the Fraunhofer IWU are explicity desired.

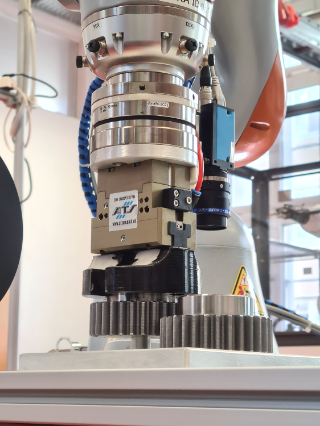

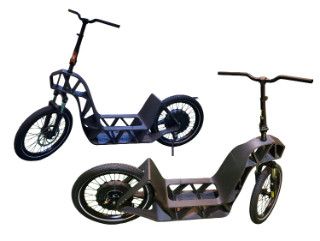

Smaller batch sizes instead of mass production, more complex production lines, increasing competitive pressure, unstable supply chains: Against this background, the Franco-German research project GreenBotAI addresses robotics. Three main objectives are in focus - ensuring production continuity even in pandemic times, strengthening Europe's independence in production automation, and significantly reducing the energy consumption of robot applications in European factories.

more info Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology