Towpregs

More cost-efficient, lighter, more eco-friendly: carbon fiber-reinforced plastics in lightweight construction

More cost-efficient, lighter, more eco-friendly: carbon fiber-reinforced plastics in lightweight construction

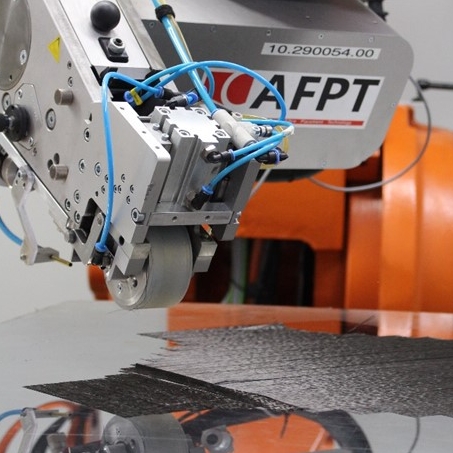

The MAREMO research project (material-efficient lightweight construction for resource-efficient mobility) focused on a key innovation: producing carbon fiber-reinforced plastics (CFRP) in a resource-efficient way for a wide range of applications. Compared to the use of flat textile semi-finished products, the deposition of fibers achieves a near-net-shape solution that is more appropriate to the requirements. This saves both weight and cost and protects the environment by minimizing scrap.

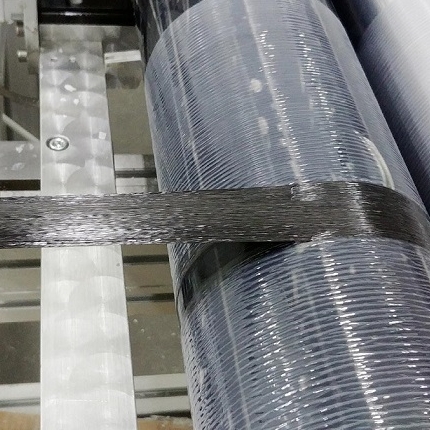

Initially, a pilot line was set up for the production and depositing of pre-impregnated fibers, so called towpregs - stable in storage and adhesive-free. Economic and ecological requirements were met with construction methods appropriate for the specific stress and corresponding production processes. However, it is a challenge to handle and impregnate a corresponding fiber architecture with resin systems. Therefore, the fibers are impregnated right at the beginning of the process chain. Due to the high reactivity of the resin systems used, low cycle times are possible in efficient production processes.

Together with its partners, Fraunhofer IWU covers the entire value chain from component and material development to manufacturing of semi-finished products and the component appropriate for the specific stress.

Fraunhofer Institute for Machine Tools and Forming Technology

Fraunhofer Institute for Machine Tools and Forming Technology